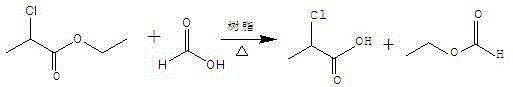

Process for preparing r-(+)-2-chloropropionic acid with high optical purity by transesterification

A technology of chloropropionic acid and transesterification, which is applied in the preparation of carboxylate, carboxylate/lactone, and oxygenated compounds, etc., can solve the problems of high production cost, many chiral impurities, affecting optical purity and the like, To achieve the effect of short production cycle, good catalytic effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] ⑴Add 600g of ethyl chloropropionate to the reactor equipped with stirring, thermometer, spherical condenser, electric heating mantle, and tail gas absorption device, turn on the stirrer, and add 1200g of chloropropionate with a mass fraction of 94% under stirring conditions 180g of formic acid and 732 resin treated with acid and alkali, slowly warming up to 54°C, and collecting the ethyl formate fraction; The distillate is mainly formic acid; after the reaction, the material and the resin are filtered and separated, and the resin is returned to the system for the next hydrolysis and separation process, which is recycled and reused.

[0018] (2) Connect the reactor to a vacuum pump, evacuate and reduce the pressure to -0.095MPa~-0.01MPa, start to heat up, and collect fractions below 108°C, which are unreacted ethyl chloropropionate and chloropropionic anhydride, etc. The remaining product in the reactor is chloropropionic acid; after cooling and rectifying, the distillat...

Embodiment 2

[0020] (1) Add 700g of ethyl chloropropionate to the reactor equipped with stirring, thermometer, spherical condenser, electric heating mantle, and tail gas absorption device, turn on the stirrer, and add 1050g of 94% mass fraction under stirring conditions Formic acid and 210g of D001 strongly acidic cationic resin treated with acid and alkali, slowly warm up to 54°C, and collect the ethyl formate fraction; when the mass of the collected ethyl formate fraction is about 350g, continue to heat up, and collect Fraction, this fraction is mainly formic acid; after the reaction, the material and resin are separated by filtration, and the resin is returned to the system for the next hydrolysis separation process, which is recycled and reused.

[0021] (2) Connect the reactor to a vacuum pump, evacuate and reduce the pressure to -0.095MPa~-0.01MPa, start to heat up, and collect fractions below 108°C, which are fractions such as unreacted ethyl chloropropionate and chloropropionic anhy...

Embodiment 3

[0023] (1) Add 400g of ethyl chloropropionate to the reactor equipped with stirring, thermometer, spherical condenser, electric heating mantle, and tail gas absorption device, turn on the stirrer, and add 1600g of chloropropionate with a mass fraction of 94% under stirring conditions Formic acid and 240g of 734 strongly acidic cationic resin treated with acid and alkali, slowly raise the temperature to 54°C, and collect the ethyl formate fraction; when the mass of the collected ethyl formate fraction is about 200g, continue to heat up, and collect the 85°C~108°C fraction , this fraction is mainly formic acid; after the reaction, the material and resin are filtered and separated, and the resin is returned to the system for the next hydrolysis and separation process, which is recycled and reused.

[0024] (2) Connect the reactor to a vacuum pump, evacuate and reduce the pressure to -0.095MPa~-0.01MPa, start to heat up, and collect fractions below 108°C, which are unreacted ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com