High Efficiency Electron Beam Irradiation Resistant Polypropylene Composites

A technology of electron beam irradiation and composite materials, which is applied in the field of medical radiation-resistant polypropylene composite materials, and can solve the problems of poor effect, limited effect, and short wavelength of electron beam irradiation of polypropylene materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

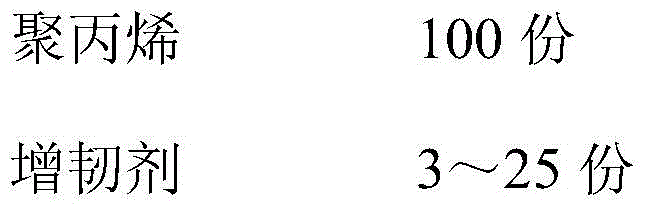

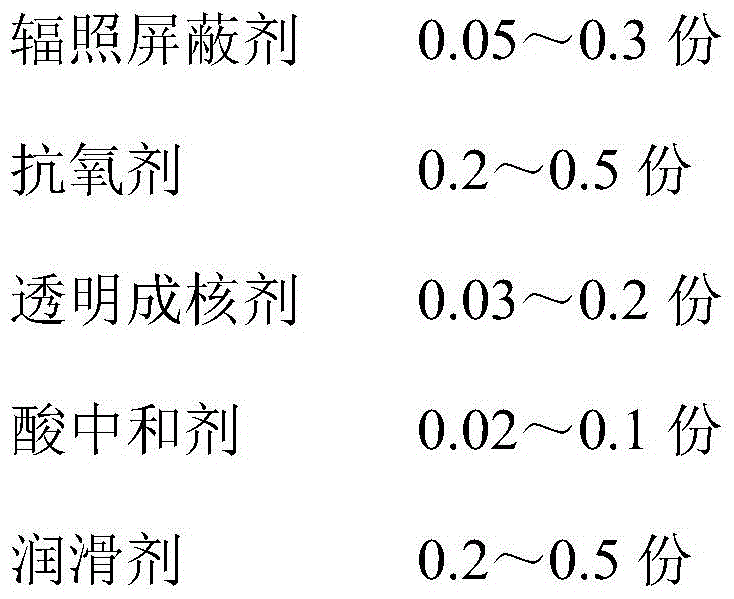

Method used

Image

Examples

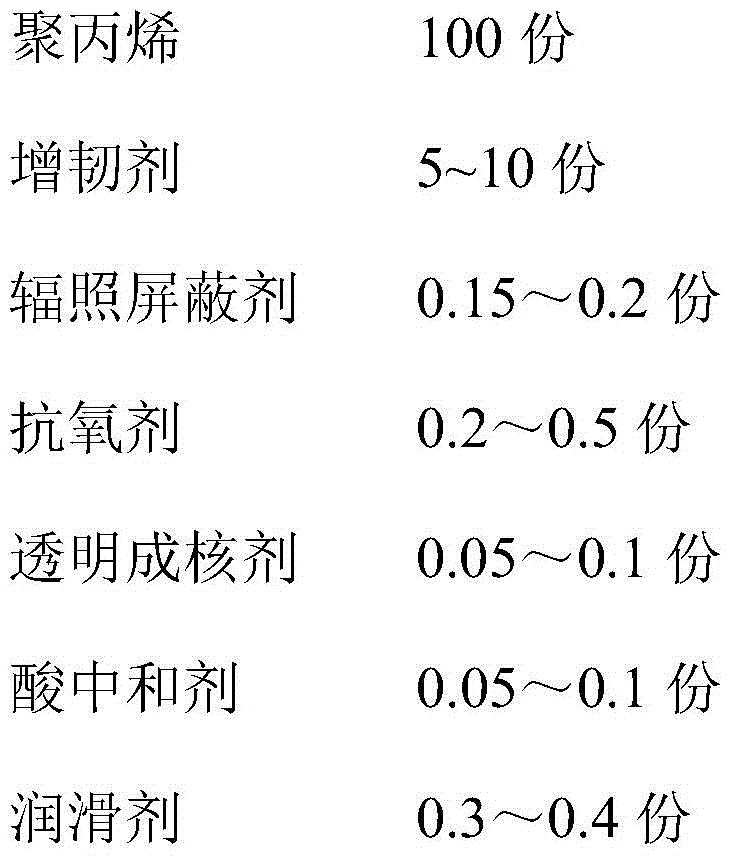

Embodiment 1

[0038]

[0039]

[0040] Randomly copolymerized polypropylene powder, toughening agent POE, radiation resistance additive, antioxidant 264, transparent nucleating agent bis(3,4 dimethylbenzylidene) sorbitol, calcium stearate and Oleamide was added to a high speed mixer and mixed for 5 minutes to obtain a premixed resin. Then add the premixed resin into the twin-screw for melt blending and extrusion. The temperature of each zone of the extruder is set as follows: the temperature from the feeding section to the die is 130-215°C, the temperature of the head and the die is 220°C, and the screw speed of the main engine It is 200r / min. The blend is extruded through a die, cooled, and granulated to obtain a polypropylene composite material. The obtained materials were tested for physical properties, chemical properties, and biological properties, and the results are listed in Table 1.

Embodiment 2

[0042]

[0043]

[0044]Randomly copolymerized polypropylene powder, toughening agent POE, radiation resistance additive, antioxidant, transparent nucleating agent bis(3,4 dimethylbenzylidene) sorbitol, calcium stearate and oil The acid amide was added to a high speed mixer and mixed for 5 minutes to obtain a premixed resin. Then add the premixed resin into the twin-screw for melt blending and extrusion. The temperature of each zone of the extruder is set as follows: the temperature from the feeding section to the die is 130-215°C, the temperature of the head and the die is 220°C, and the screw speed of the main engine It is 200r / min. The blend is extruded through a die, cooled, and granulated to obtain a polypropylene composite material. The obtained materials were tested for physical properties, chemical properties, and biological properties, and the results are listed in Table 1.

Embodiment 3

[0046]

[0047] Randomly copolymerized polypropylene powder, toughening agent SEBS, radiation resistance additive, antioxidant 264, transparent nucleating agent bis(3,4 dimethylbenzylidene) sorbitol, calcium stearate and Oleamide was added to a high speed mixer and mixed for 5 minutes to obtain a premixed resin. Then add the premixed resin to the twin-screw for melt blending and extrusion. The temperature of each zone of the extruder is set as follows: the temperature from the feeding section to the die is 135-220°C, the temperature of the head and the die is 225°C, and the screw speed of the main engine It is 200r / min. The blend is extruded through a die, cooled, and granulated to obtain a polypropylene composite material. The obtained materials were tested for physical properties, chemical properties, and biological properties, and the results are listed in Table 1.

[0048] Table 1 Physical properties, chemical properties, biological properties of materials

[0049] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com