Separator for lithium ion battery and preparation method of separator

A lithium-ion battery and diaphragm technology, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve problems affecting battery performance, increased diaphragm thickness, and low surface energy. Achieve precise control of coating thickness, improve battery performance, and lower process temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

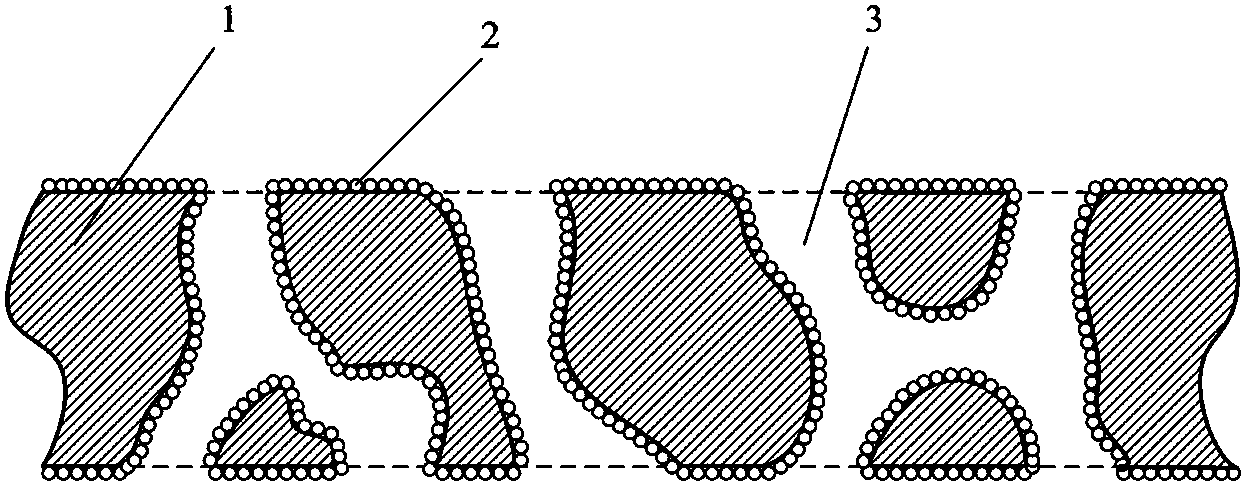

[0034] A separator for lithium-ion batteries, such as figure 1 As shown, it includes a polymer microporous membrane substrate, the surface of the substrate and the inner wall of the micropore channel are covered with a nano-oxide layer, wherein the substrate is polypropylene, the thickness of the substrate is 20 μm, the porosity is 40%, and the nano-oxide layer is The material layer is an aluminum oxide layer. The aluminum oxide layer has a thickness of 10-20 nm.

[0035] Its preparation method comprises the following steps:

[0036] (1) The biaxially stretched polypropylene microporous membrane substrate with a thickness of 20 μm and a porosity of 40% was first treated with a 3mol / L nitric acid solution for 10 minutes, and then soaked in a 1mol / L sodium hydroxide solution for 10 minutes. Wash with deionized water, then bake at 50°C for 1h;

[0037] (2) Put the microporous membrane obtained in step (1) into the cavity of the atomic layer deposition instrument, vacuumize an...

Embodiment 2

[0060] A separator for a lithium ion battery, comprising a polymer microporous film base material, the surface of the base material and the inner wall of the micropore channel are covered with nano-sized oxygen

[0061] The compound layer, wherein the substrate is polyethylene, the thickness of the substrate is 5 μm, the porosity is 30%, and the nano-oxide layer is an alumina layer. The aluminum oxide layer has a thickness of 10-20 nm.

[0062] Its preparation method comprises the following steps:

[0063] (1) The biaxially oriented polyethylene microporous membrane substrate with a thickness of 5 μm and a porosity of 30% was first treated with a 3mol / L nitric acid solution for 1min, and then soaked in a 1mol / L sodium hydroxide solution for 1min. Wash with deionized water, then bake at 40°C for 3h;

[0064] (2) Place the microporous membrane obtained in step (1) in the cavity of the atomic layer deposition instrument, vacuumize and heat to 100°C for 1 min.

[0065] (3) Introd...

Embodiment 3

[0072] A separator for a lithium ion battery, comprising a polymer microporous film base material, the surface of the base material and the inner wall of the micropore channel are covered with nano-sized oxygen

[0073] The compound layer, wherein the substrate is polyvinylidene chloride, the thickness of the substrate is 60 μm, the porosity is 60%, and the nano-oxide layer is an alumina layer. The aluminum oxide layer has a thickness of 80-100 nm.

[0074] Its preparation method comprises the following steps:

[0075] (1) The biaxially stretched polyvinylidene chloride microporous membrane substrate with a thickness of 60 μm and a porosity of 60% was first treated with a 3mol / L nitric acid solution for 15 minutes, and then soaked in a 1mol / L sodium hydroxide solution for 10 minutes Finally, wash with deionized water, and then bake at 80°C for 0.5h;

[0076] (2) Put the microporous membrane obtained in step (1) into the chamber of the atomic layer deposition instrument, vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com