Cuttlefish paste and preparation method thereof

A technology of cuttlefish slippery and production method, which is applied in the field of food processing, can solve the problems that cuttlefish slippery products have few appearances, functions and product quality need to be improved, etc., and achieves the effects of saving raw materials, convenient preparation, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

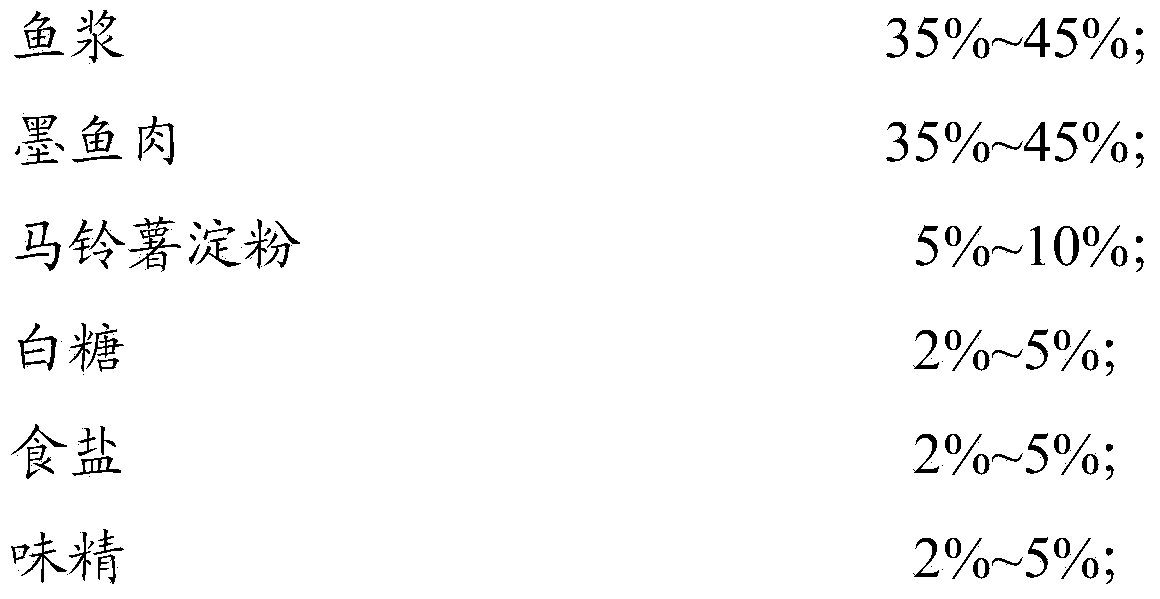

[0026] A kind of preparation method of cuttlefish slip, described cuttlefish slip is made from the raw material of following mass percentage:

[0027]

[0028] The rest is water, and the temperature of the water is 0°C;

[0029] Described preparation method specifically comprises the following steps:

[0030] (1) Clean the cuttlefish meat, then put it into a shredder and cut it into cubes for later use;

[0031] (2) Put the fish paste into a chopping machine and chop it into fine particles for later use;

[0032] (3) Add the fish paste chopped in step (2) into the barrel of the chopping machine, and stir until the fish paste has a certain viscosity;

[0033] (4) add white granulated sugar, salt, monosodium glutamate and the fish paste gained in step (3) into a chopping machine and beat in a barrel and stir evenly;

[0034] (5) Add the potato starch into the barrel of the chopping machine in step (4), and stir until the slurry is fine and elastic so that the fish paste is...

Embodiment 2

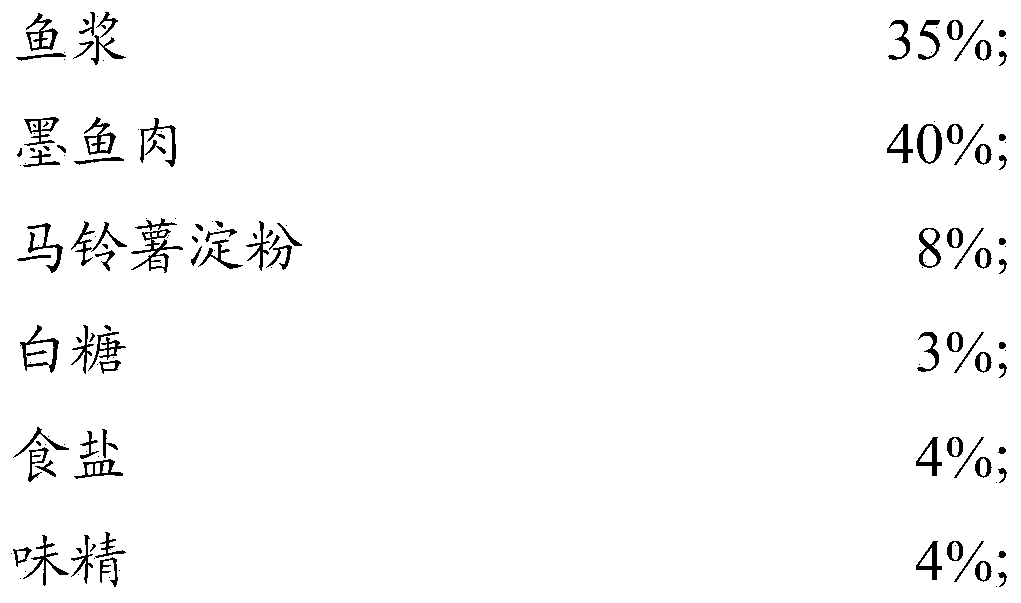

[0038] 1, a kind of preparation method of cuttlefish slip, described cuttlefish slip is made by the raw material of following mass percentage:

[0039]

[0040] Described preparation method specifically comprises the following steps:

[0041] (1) Clean the cuttlefish meat, then put it into a shredder and cut it into cubes for later use;

[0042] (2) Put the fish paste into a chopping machine and chop it into fine particles for later use;

[0043] (3) Add the fish paste chopped in step (2) into the barrel of the chopping machine, and stir until the fish paste has a certain viscosity;

[0044] (4) add white granulated sugar, salt, monosodium glutamate and the fish paste gained in step (3) into a chopping machine and beat in a barrel and stir evenly;

[0045] (5) Add the potato starch into the barrel of the chopping machine in step (4), and stir until the slurry is fine and elastic so that the fish paste is mixed;

[0046] (6) Add the diced cuttlefish meat in step (1) into ...

Embodiment 3

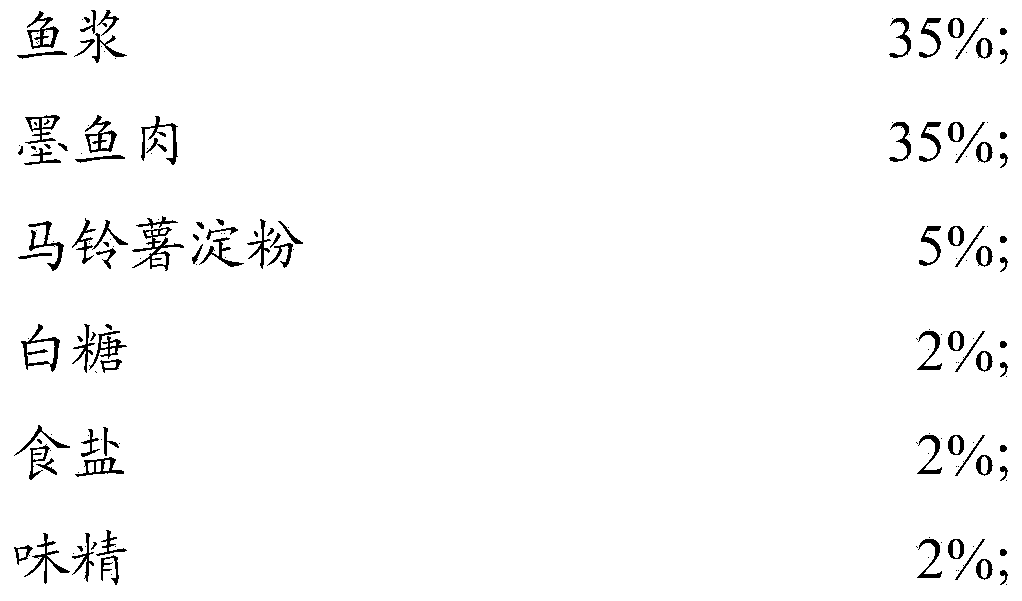

[0049] 1, a kind of preparation method of cuttlefish slip, described cuttlefish slip is made by the raw material of following mass percentage:

[0050]

[0051]

[0052] The rest is water, and the temperature of the water is 5°C;

[0053] Described preparation method specifically comprises the following steps:

[0054] (1) Clean the cuttlefish meat, then put it into a shredder and cut it into cubes for later use;

[0055] (2) Put the fish paste into a chopping machine and chop it into fine particles for later use;

[0056] (3) Add the fish paste chopped in step (2) into the barrel of the chopping machine, and stir until the fish paste has a certain viscosity;

[0057] (4) add white granulated sugar, salt, monosodium glutamate and the fish paste gained in step (3) into a chopping machine and beat in a barrel and stir evenly;

[0058] (5) Add the potato starch into the barrel of the chopping machine in step (4), and stir until the slurry is fine and elastic so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com