Compound containing polacrilin potassium-paroxetine

A technology of polacrine potassium and compound, which is applied in the directions of non-active ingredient medical preparation, drug combination, pill delivery, etc., can solve the problems of large compound loss, poor stability, sticking and punching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

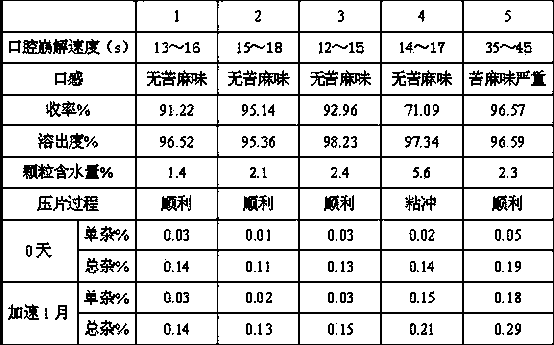

[0012] In this embodiment, the ratio of paroxetine to polacrilin potassium is 1:1, the ratio of polacrilin potassium and paroxetine solid to water is 1:50, the selected organic solvent is ethanol, and the ratio of alcohol to water is 1:5.

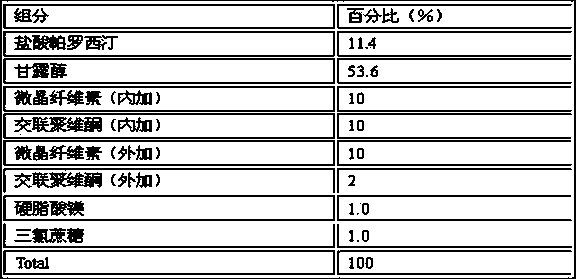

[0013]

[0014] Preparation process: Add 100g of polacrilin potassium and 114g of paroxetine hydrochloride into 10kg of water and stir for 1 hour to fully disperse and form a complex. Add 2000L of ethanol and let stand for 12h. Remove the supernatant, and then Add 536g mannitol and 100g microcrystalline cellulose to the precipitate, stir and granulate using a wet granulator, granulate with a 24-mesh sieve, dry in a fluidized bed at 50°C, and after sizing, add 100g microcrystalline cellulose, 2g Cross-linked povidone, 1g magnesium stearate, 1g silicon dioxide, 1g acesulfame K, mix evenly, calculate the tablet weight according to the content of paroxetine in the granules and press the tablet, the yield can reach more than 90%, and the disin...

Embodiment 2

[0016] In this embodiment, the ratio of paroxetine to polacrilin potassium is 1:3, and the ratio of polacrilin potassium and paroxetine solid to water is 1:30.

[0017]

[0018] Preparation process: Weigh 114g of paroxetine hydrochloride and 300g of polacrilin potassium, add them to 2000g of water, stir to make them fully dispersed, and form a complex. After standing still, remove the supernatant, then add 60ml of ethanol, and add 200g of Microcrystalline cellulose, 356g mannitol, stirred evenly with a wet granulator, granulated with a 24-mesh sieve, spray-dried at 50°C and granulated, then added 200g microcrystalline cellulose, 2g crospovidone, 1g stearin magnesium oxide, 1g silicon dioxide, 1g acesulfame K, mixed evenly, according to the content of paroxetine in the granules, the tablet weight was converted and pressed into tablets, the yield could reach more than 90%, the disintegration speed was 15±3s, the taste was slightly sweet and cool feeling.

Embodiment 3

[0020] In this embodiment, the ratio of paroxetine to polacrilin potassium is 1:2, and the ratio of polacrilin potassium and paroxetine solid to water is 1:60.

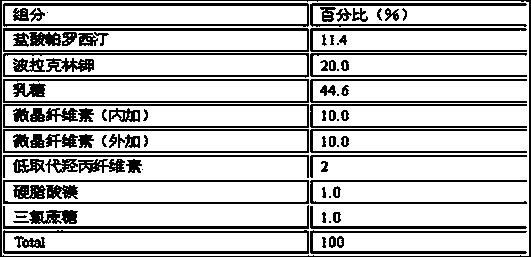

[0021]

[0022] Preparation process: Weigh 114g of paroxetine hydrochloride and 200g of polacrilin potassium, add them to 1.8kg of water, stir to make them fully dispersed, and form a complex. After standing still, remove the supernatant, then add 40ml of ethanol, and add 100g of microcrystalline cellulose, 446g of lactose, stirred evenly with a wet granulator, granulated with a 20-mesh sieve, dried in an oven at 50°C and granulated, then added 100g of microcrystalline cellulose, 2g of low-substituted hydroxypropyl cellulose, and 1g of hard Magnesium fatty acid, 1g of acesulfame K, mixed evenly, according to the content of paroxetine in the granules, the weight of the tablet was converted and compressed, the yield can reach more than 90%, the disintegration speed is 15±3s, the taste is slightly sweet and cool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com