Preparation method and application of MnOOH/Ag nano-composite material

A nano-composite material and nano-rod technology, which is applied in the field of preparation of nOOH/Ag nano-composite materials, can solve the problems such as the inability to control the morphology of precious metals, and achieve the effects of superior catalytic performance, high repeatability and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of MnOOH / Ag nano composite material, comprises the following steps:

[0041] a. Disperse 15 mg of the raw material MnOOH nanorods in 30 mL of 1 mol / L sodium salt solution, sonicate for 20 min, add 1 mL of polystyrene sodium sulfonate (PSS) under stirring, and stir for 1 h. Centrifuge and wash the pellet 5 times with deionized water.

[0042] B, the product obtained in step (a) is dispersed in 50mL H 2 O, add 5mg AgNO 3 , and added 100mg of PVP, stirred for 1h.

[0043] c. Add 200 μL 37% HCHO (density 1.08 g / ml) to the system, add 500 μL NH 3 .H 2 O to adjust the pH to be alkaline, continue stirring for 1 h, centrifuge, wash with deionized water and absolute ethanol several times, and dry at 60°C. The MnOOH / Ag nanosheet composite was obtained.

[0044] The reducing agents HCHO and NH 3 .H 2 O is replaced by hydrazine hydrate, under the above experimental conditions, MnOOH / Ag nanoparticle composites can be obtained

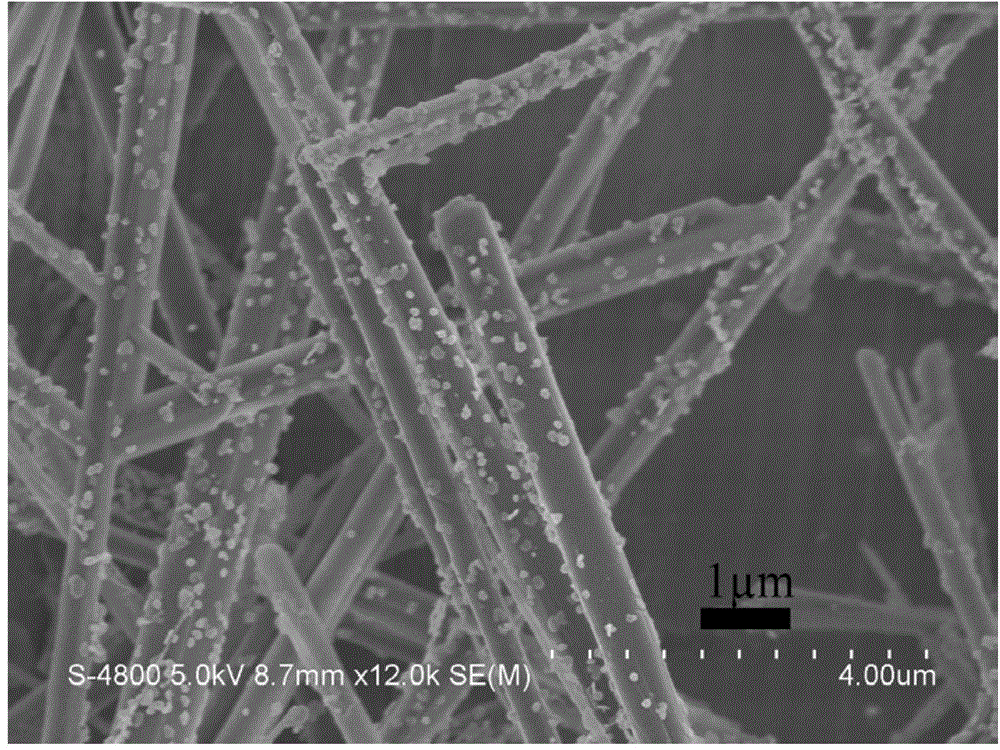

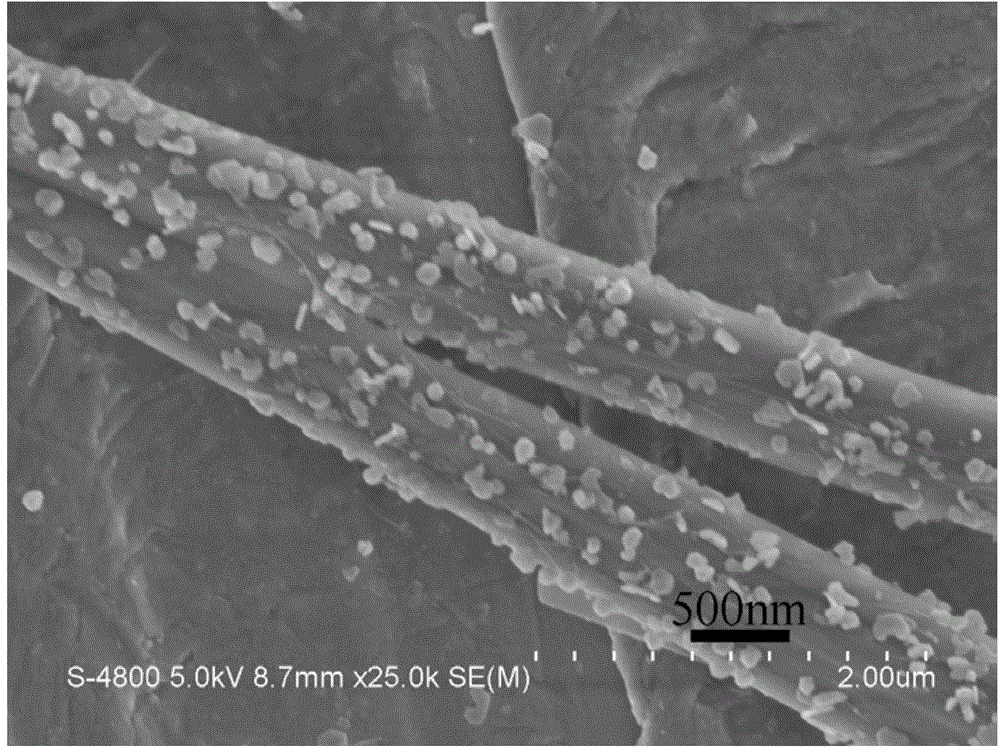

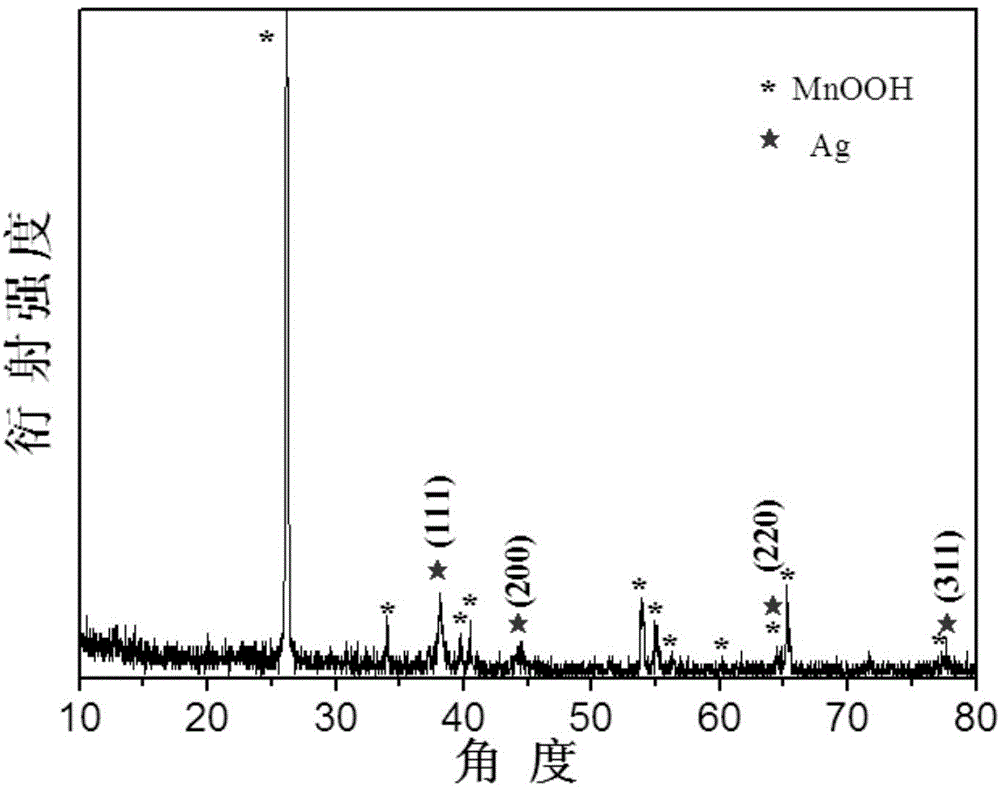

[0045] Fig. 1 (a)...

Embodiment 2

[0049] a. Disperse 15 mg of the raw material MnOOH nanorods in 30 mL of 1 mol / L sodium salt solution, sonicate for 30 min. Add 1 mL of polystyrene sodium sulfonate (PSS) under stirring, and stir for 1 h. Centrifuge and wash the pellet 6 times with deionized water.

[0050] B, the product obtained in step (a) is dispersed in 50mL H 2 O, add 5mg AgNO 3 , and added 15mg of PVP, stirred for 1h.

[0051] c. Add 200 μL 37% HCHO (density 1.08 g / ml) to the system, add 500 μL NH 3 .H 2 O to adjust the pH to be alkaline, continue stirring for 1 h, centrifuge, wash with deionized water and absolute ethanol several times, and dry at 60°C. The MnOOH / Ag nanosheet composite was obtained.

Embodiment 3

[0053] a. Disperse 15 mg of raw material MnOOH nanorods in 30 mL of 1 mol / L sodium salt solution, ultrasonicate for 25 min, add 1 mL of polystyrene sodium sulfonate (PSS) under stirring, and stir for 1 h. Centrifuge and wash the pellet 5 times with deionized water.

[0054] B, the product obtained in step (a) is dispersed in 50mL H 2 O, add 5mg AgNO 3 , and added 75mgPVP, stirred for 1h.

[0055] c. Add 200 μL 37% HCHO (density 1.08 g / ml) to the system, and 500 μL NH 3 .H 2 O to adjust the pH to be alkaline, continue stirring for 1 h, centrifuge, wash with deionized water and absolute ethanol several times, and dry at 60°C. The MnOOH / Ag nanosheet composite was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com