A treatment process for high-concentration waste liquid in the circuit board industry

A waste liquid treatment, high-concentration technology, applied in water/sewage treatment, aerobic process treatment, anaerobic digestion treatment, etc., can solve high energy consumption, low economic and operational feasibility, one-time investment Problems such as high cost to achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

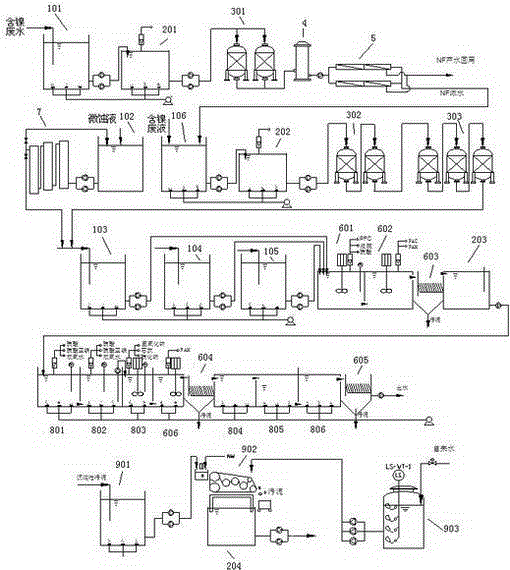

Image

Examples

Embodiment 1

[0070] (1) Separately collect the high-concentration organic developing defilming waste liquid, acidic waste liquid, alkaline waste liquid, micro-etching liquid, nickel-containing waste liquid and nickel-containing wastewater in the circuit board industry to the corresponding collection tank, and the nickel-containing wastewater collection tank (101) Collect nickel-containing wastewater, the slightly turbid liquid collection tank (102) collects the slightly turbid liquid, the acid waste liquid collection tank (103) collects acidic waste liquid, the alkaline waste liquid collection tank (104) collects alkaline waste liquid, organic The waste liquid collection tank (105) collects organic waste liquid, and the nickel-containing waste liquid collection tank (106) collects nickel-containing waste liquid;

[0071] (2) After the nickel-containing wastewater is pumped to the intermediate tank I (201) to adjust the pH, it is filtered by the sand filter tank (301) and the security filter (4...

Embodiment 2

[0083] (1) Separately collect the high-concentration organic developing defilming waste liquid, acidic waste liquid, alkaline waste liquid, micro-etching liquid, nickel-containing waste liquid and nickel-containing wastewater in the circuit board industry to the corresponding collection tank, and the nickel-containing wastewater collection tank (101) Collect nickel-containing wastewater, the slightly turbid liquid collection tank (102) collects the slightly turbid liquid, the acid waste liquid collection tank (103) collects acidic waste liquid, the alkaline waste liquid collection tank (104) collects alkaline waste liquid, organic The waste liquid collection tank (105) collects organic waste liquid, and the nickel-containing waste liquid collection tank (106) collects nickel-containing waste liquid;

[0084] (2) After the nickel-containing wastewater is pumped to the intermediate tank I (201) to adjust the pH, it is filtered by the sand filter tank (301) and the security filter (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com