A method for distilling alcohol by mixing straw cellulose dry matter with liquid alcohol fermented mash

A straw cellulose and alcohol fermentation technology, applied in fermentation, biofuels, etc., can solve problems such as high alcohol production costs, liquid wine tank pollution, and difficult treatment, and achieve the goals of reducing production costs, increasing alcohol content, and increasing added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

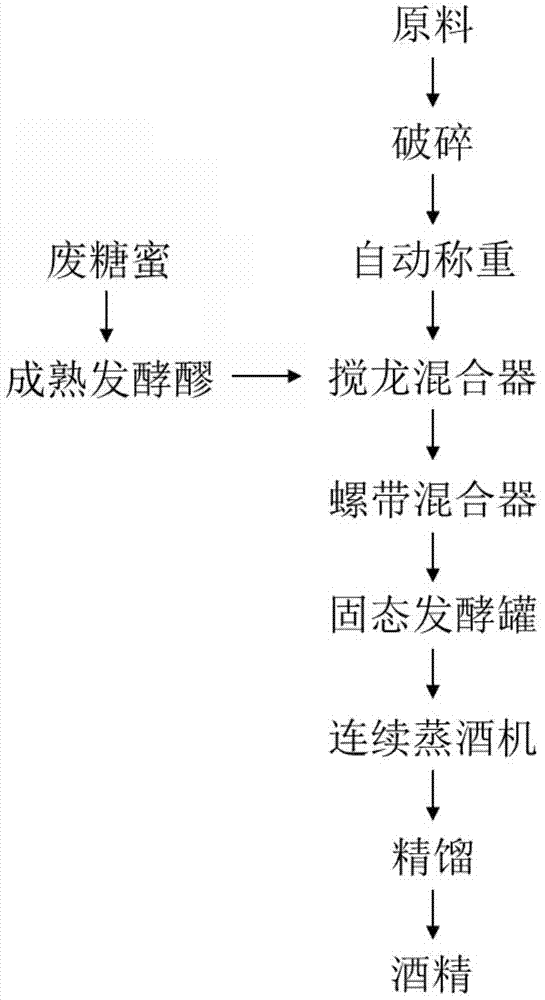

[0019] A method for distilling alcohol by mixing straw cellulose dry matter with liquid alcohol fermentation mash, comprising the following steps:

[0020] Step 1: Using corn as a raw material, ferment for 50 hours to prepare a mature liquid alcohol fermented mash with an alcohol content of 11% and a residual sugar content of less than 0.5%; the liquid alcohol fermented mash is then mixed with acidified waste molasses to make the liquid The fermentable sugar content in the alcohol fermented mash is adjusted to 2%, to obtain mixture A;

[0021] Step 2: Crushing the cellulose dry matter of corn stalks with a moisture content of 14% into small pieces with a length of 5-10 mm to obtain raw material B containing cellulose dry matter of straw;

[0022] Step 3: Mix the mixture A obtained in step 1 with the raw material B obtained in step 2 at a ratio of 5:3 and put it into a stirring mixer for the first initial mixing with liquid yeast, and then enter the ribbon mixer to fully Mix e...

Embodiment 2

[0027] A method for distilling ethanol by mixing straw cellulose dry matter with liquid fermented mash, comprising the following steps:

[0028] Step 1: using dried cassava as raw material, fermenting for 58 hours to prepare a mature liquid alcoholic fermented mash with an alcohol content of 12.5% and a residual sugar content of less than 0.2%; the liquid alcoholic fermented mash is then mixed with acidified waste molasses to make The fermentable sugar content in the liquid alcohol fermented mash is adjusted to 4%, to obtain mixture A;

[0029] Step 2: breaking the rice straw with a moisture content of 14% into small pieces of 1-5 mm, and then mixing the rice husks accounting for 10% of the rice straw to obtain the straw-containing cellulose dry matter raw material B;

[0030] Step 3: Mix the mixture A obtained in step 1 with the raw material B obtained in step 2 at a ratio of 5:2 and put it into a stirring mixer for the first initial mixing with liquid yeast, and then enter...

Embodiment 3

[0035] A method for distilling ethanol by mixing straw cellulose dry matter with liquid fermented mash, comprising the following steps:

[0036] Step 1: Using corn as raw material, ferment for 65 hours to prepare a mature liquid alcohol fermented mash with an alcohol content of 14% and a residual sugar content of less than 0.2%; the liquid alcohol fermented mash is then mixed with acidified waste molasses to make the liquid The fermentable sugar content in the alcohol fermented mash is adjusted to 4%, to obtain mixture A;

[0037] Step 2: crushing cotton stalks and dry bagasse with a moisture content of 14% into small pieces with a length of 5-20 mm in a ratio of 1:2, and then mixing them with sawdust to obtain dry material B containing straw cellulose;

[0038] Step 3: Mix the mixture A obtained in step 1 with the raw material B obtained in step 2 at a ratio of 5:2.5 and put it into a stirring mixer for the first initial mixing with liquid yeast, and then enter the ribbon mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com