A method for producing 1,3-propanediol with high efficiency and high conversion rate

A high conversion rate, propylene glycol technology, applied in the field of bioengineering, can solve the problems of 3-hydroxypropionic acid accumulation, difficulty, and small production promotion effect, and achieve the effect of high production intensity, high product concentration and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The identification of embodiment 1, KG

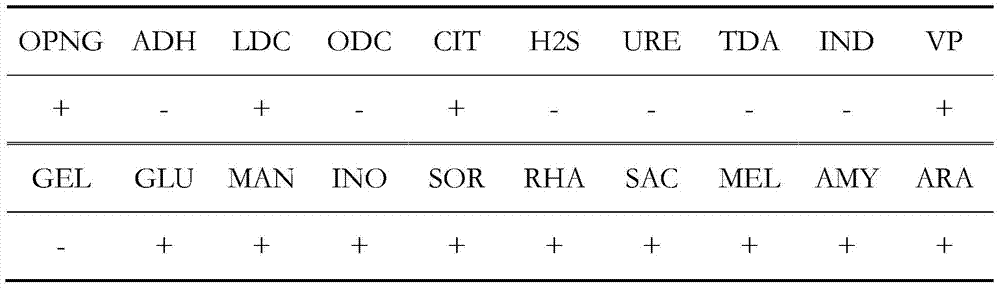

[0030] The physical and chemical indicators of KG were analyzed with the Gram-negative intestinal microorganism physicochemical kit API20E (Mérieux, France). The physical and chemical identification steps are based on the API20E operation manual, and the identification results are shown in Table 1. According to the API20E manual, KG belongs to Klebsiella pneumoniae.

[0031] Table 1: API20E physical and chemical identification results

[0032]

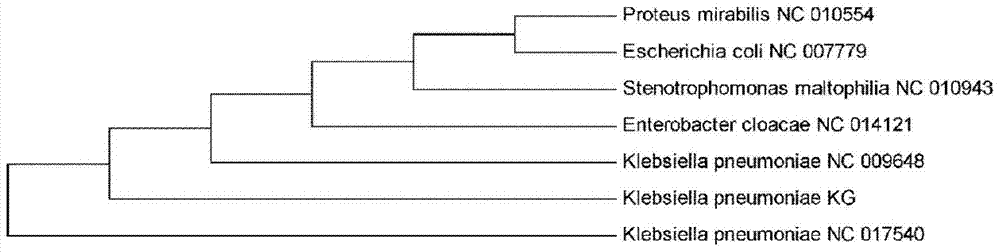

[0033] The bacterial 16srDNA universal primers 27f (AGAGTTTGATCCTGGCTCA) and 1394r (TACGGCTACCTTGTTACGAGTT) were used to amplify the 16srNDA gene of KG by PCR using the KG genome as a template. The homologous comparison of 16srNDA showed that KG belongs to Klebsiella pneumoniae (attached figure 1 ).

Embodiment 2

[0034] Embodiment 2, KG can produce 1,3-PD with high conversion rate

[0035] Put KG and the control bacterium K.pneumoniae ATCC49790 into a 250ml shaker flask (50ml liquid volume) for seed cultivation for 20 hours, and then put it into a 5L fermenter (2L liquid volume of the fermentation broth), according to the process shown below Conditions control the fermentation process.

[0036] The initial glycerol concentration is 60g / L, the fermentation temperature is 35°C; the ventilation rate is 1.0vvm; the stirring speed is 20rpm; the pH value is controlled by adding NaOH solution to 5.5-7.5 during the fermentation process. In each period of fermentation, the glycerin concentration is controlled at 10-60 g / L by supplementing glycerin solutions with different concentrations, and the fermentation ends in 30 hours.

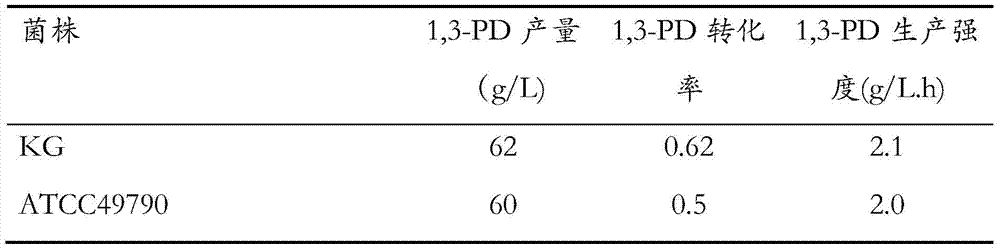

[0037] Shown in fermentation result table 2:

[0038] Table 2: Fermentation comparison of KG and ATCC49790

[0039]

[0040] It can be seen from Table 2 that compare...

Embodiment 3

[0041] Embodiment 3, construction contains the expression plasmid of moderate expression promoter Tac

[0042] The backbone of the expression vector was pET28a, and the Tac promoter sequence was pGEX-4T-1. Using a pair of primers containing the BglII-EcoRI restriction site (GGAagatctACGTTATCGACTGCACGG, GGCgaattcCATGAATACTGTTTCCTGT), the Tac promoter region 260bp (SEQ ID NO.2) on pGEX-4T-1 was amplified and inserted into the BglII-EcoRI of pET28a Restriction sites were used to replace the original T7 promoter region of pET28a to construct an expression vector pETac capable of moderate gene expression in Klebsiella.

[0043] In order to prove that pETac can moderately express genes in Klebsiella pneumoniae, a reporter gene (lacZ) was used to analyze the promoter Tac. lacZ (the gene encoding galactosidase) was derived from Escherichia coli. A pair of primers containing HindIII-XhoI (CACaagcttGCGTTTTACAACGTCGTGAC, CCGctcgagTTATTTTTGACACCAGACCA) was used to amplify the 3075bp lac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com