Micro-nano pore-containing chlorine-alkali ion membrane preparation method

A technology of ion-exchange membrane and ion-exchange membrane, applied in the direction of diaphragm, organic diaphragm, electrolysis process, etc., can solve problems affecting the performance of chlor-alkali membrane, achieve excellent high-temperature thermal stability, reduce transmission resistance, and improve mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

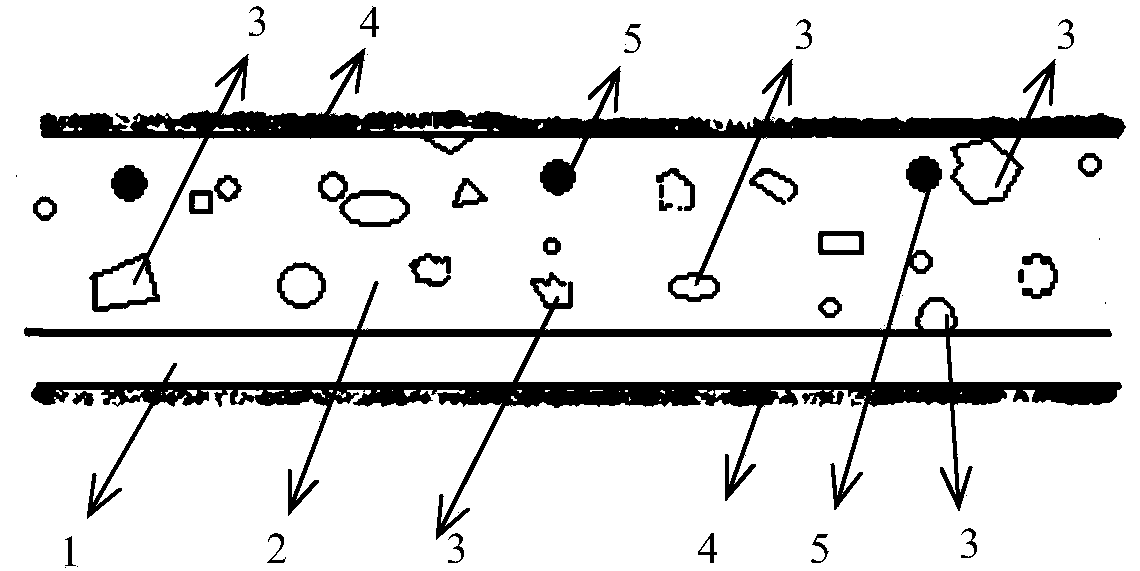

Image

Examples

Embodiment 1

[0038] a. Preparation of resin pellets

[0039] The perfluorosulfonic acid resin is the powder obtained by copolymerization of tetrafluoroethylene and perfluoro 3-oxa-4-butenesulfonyl fluoride, the ion exchange capacity is 0.99mmol / g, and the sodium chloride particles ( It can be prepared according to the literature method: Zhang Li, Cheng Humin, Ma Jiming. Preparation of NaCl nanoparticles in non-aqueous inverse microemulsion [J]. Acta Physicochemical Sinica, 2002, 18(01): 79-81.) and the above-mentioned perfluorosulfuronium The acid resin powder is fully mixed according to the mass ratio of 9:100, and then melted, extruded and granulated to obtain perfluorosulfonic acid resin pellets containing nano-sodium chloride particles.

[0040] The powder obtained by copolymerization of tetrafluoroethylene and perfluoro-4,7-dioxa-5-methyl-8-nonenoate methyl ester is melt-extruded and granulated to obtain pellets of perfluorocarboxylic acid resin. The capacity is 0.95mmol / g.

[0041]...

Embodiment 2

[0048] (1) Preparation of resin pellets

[0049] Perfluorosulfonic acid resin is a powder obtained by copolymerization of tetrafluoroethylene, hexafluoropropylene and perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluoride, with an ion exchange capacity of 1.06mmol / g , the potassium chloride powder (dissolvable ultrafine powder) with a particle size of 100nm to 10μm is fully mixed with the above-mentioned perfluorosulfonic acid resin powder (mass ratio 15:100), and then melted and extruded to obtain soluble ultrafine powder. Granules of fine powder perfluorosulfonic acid resin. The powder obtained by copolymerization of tetrafluoroethylene and perfluoro 4,7-dioxa-5methyl-8-nonenoate methyl ester has an ion exchange capacity of 0.97mmol / g, and the perfluoro Pellets of carboxylic acid resin.

[0050] (2) Membrane preparation and reinforcement

[0051] Using the above-mentioned perfluorocarboxylic acid resin pellets and the perfluorosulfonic acid resin pellets containing potass...

Embodiment 3

[0057] Step (1), step (2) and step (3) are the same as in Example 1, except that the average particle size of the dissolvable ultrafine powder in step (1) is a hollow structure sodium chloride powder with an average particle size of 100 nm to 10 μm (It can be prepared according to the literature method: Tao Yuhong et al., Preparation and Surface Analysis of Ultrafine Sodium Chloride Powder with Hollow Structure, Inorganic Salt Industry, 2010, 42(7): 31-33).

[0058] The prepared ion membrane tensile strength of the present embodiment is 39MPa, can be used for the ion exchange membrane in the chlor-alkali ion membrane electrolyzer, at 7.5kA / m 2 Under the current density, the mass ratio concentration of the cathode NaOH solution is 32%, the concentration of the anode brine entering the tank is 305g / L, the concentration of the brine leaving the tank is 203g / L, the tank temperature is 85-87°C, the active cathode is under the conditions of 1mm pole distance According to the test, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com