Processing process and formula for red jujube drink

A processing technology and technology for red dates, which are applied in multi-step food processing, food preparation, food science and other directions, can solve the problems affecting the promotion of red dates beverage products, reduce edible quality, and have poor seasoning effects, and achieve the elimination of dates. Guarantee the effect of health care function and elegant taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

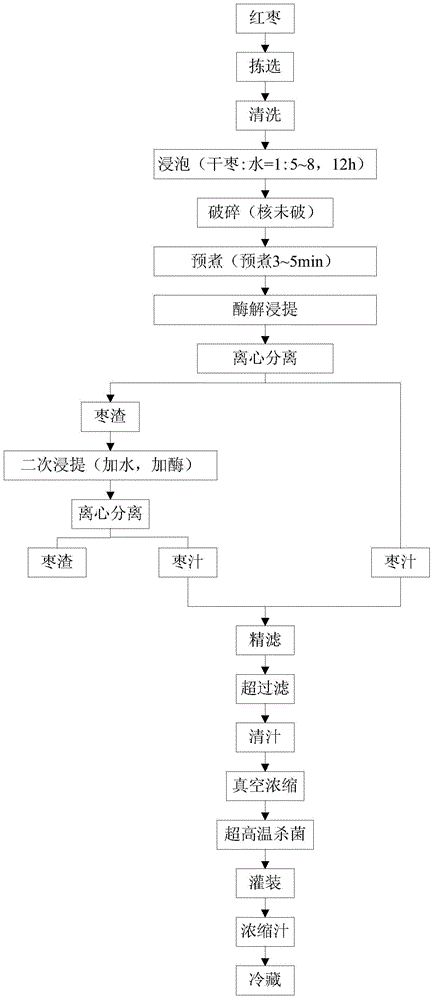

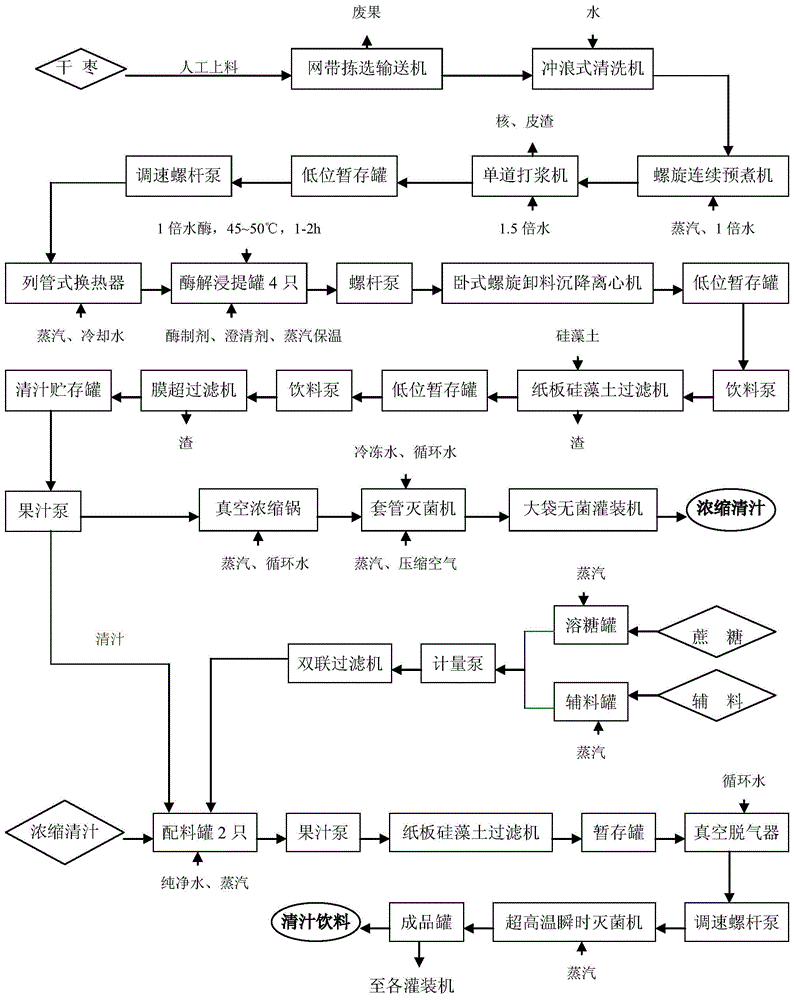

Method used

Image

Examples

Embodiment 1

[0062] Step 1: Select and weigh a certain quality of red dates, wash them by surfing, soak the red dates and pre-cook them at 90°C for 3 minutes, crush them and put them in a container. Add purified water to the container to obtain jujube pulp, heat the temperature to 50°C, add pectinase to the container for enzymolysis reaction according to the mass ratio of pectinase and jujube at a ratio of 1:100, the enzymolysis temperature is 45°C, and the temperature is constant Extract for 3 hours, and centrifuge to obtain jujube juice and jujube dregs;

[0063] Step 2: finely filter the above-mentioned jujube juice with diatomaceous earth on a cardboard, and ultra-micro-filter the membrane, and the filtrate is red jujube clear juice, which is collected and stored for later use;

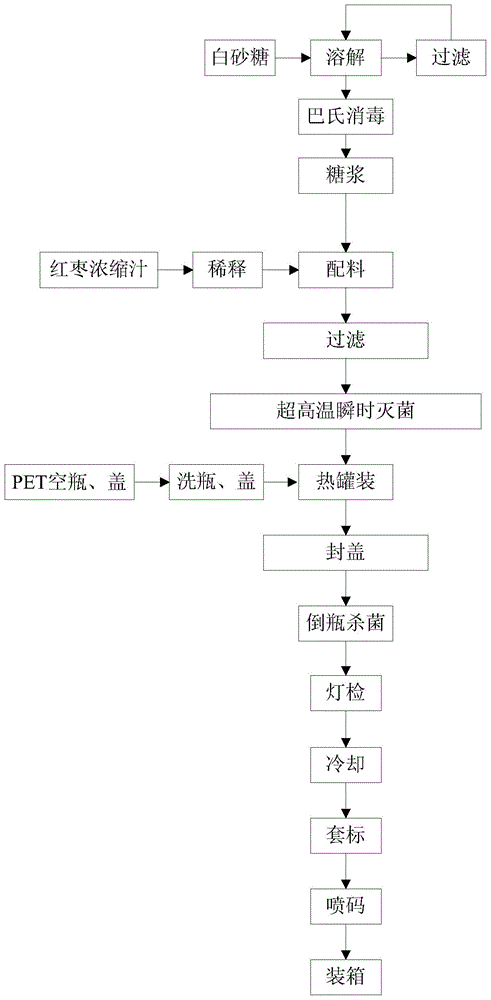

[0064] Step 3: in parts by mass, 300 parts of jujube clear juice per 1000 parts, 2 parts of honey, 30 parts of white sugar, 0.2 part of citric acid, 0.4 part of sodium citrate, 0.2 part of malic acid Divide t...

Embodiment 2

[0067] Step 1: Select and weigh a certain quality of red dates, wash them by surfing, soak the red dates and pre-cook them at 92°C for 4 minutes, crush them and put them in a container. Add pure water to the container to obtain jujube pulp, heat the temperature to 60°C, add pectinase to the container for enzymolysis reaction according to the mass ratio of pectinase to red dates as 1.1:100, the enzymolysis temperature is 50°C, and the temperature is constant Extract for 2 hours, and centrifuge to obtain jujube juice and jujube dregs;

[0068] Step 2: finely filter the above-mentioned jujube juice with diatomaceous earth on a cardboard, and ultra-micro-filter the membrane, and the filtrate is red jujube clear juice, which is collected and stored for later use;

[0069] Step 3: in parts by mass, 350 parts of jujube clear juice per 1000 parts, 3 parts of honey, 40 parts of white granulated sugar, 0.3 part of citric acid, 0.5 part of sodium citrate, 0.2 part of malic acid and 0.4 ...

Embodiment 3

[0072] Step 1: Select and weigh a certain quality of red dates, wash them by surfing, soak the red dates and pre-cook them at 98°C for 5 minutes, crush them and put them in a container. Add purified water to obtain jujube pulp, heat the temperature to 55°C, and perform an enzymatic hydrolysis extraction. According to the mass ratio of pectinase to jujube 0.65:100, add pectinase into the container for enzymolysis reaction, enzymolysis The temperature is 48°C, constant temperature leaching for 1.5h, the first centrifugation to obtain jujube juice and jujube dregs; the jujube dregs and pure water are mixed at a mass ratio of 1:3, and the second enzymatic extraction is carried out. The mass ratio of jujube is 0.4:100. Pectinase is added to the container for enzymolysis reaction. The enzymolysis temperature is 48°C, constant temperature leaching for 1.5h, the second centrifugation to obtain jujube juice and jujube dregs. The separated jujube juice is mixed;

[0073] Step 2: finely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com