Method for preparing activated carbon for super capacitor with fruit shells as raw material and application of activated carbon

A technology of supercapacitor and activated carbon, which is applied in the preparation of activated carbon for supercapacitor and the field of activated carbon for supercapacitor, can solve the problems of inability to completely remove the surface functional groups of activated carbon, high cost, and general impurity removal effect, and achieves improved cycle life and reduced Preparation cost, the effect of reducing the bloating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

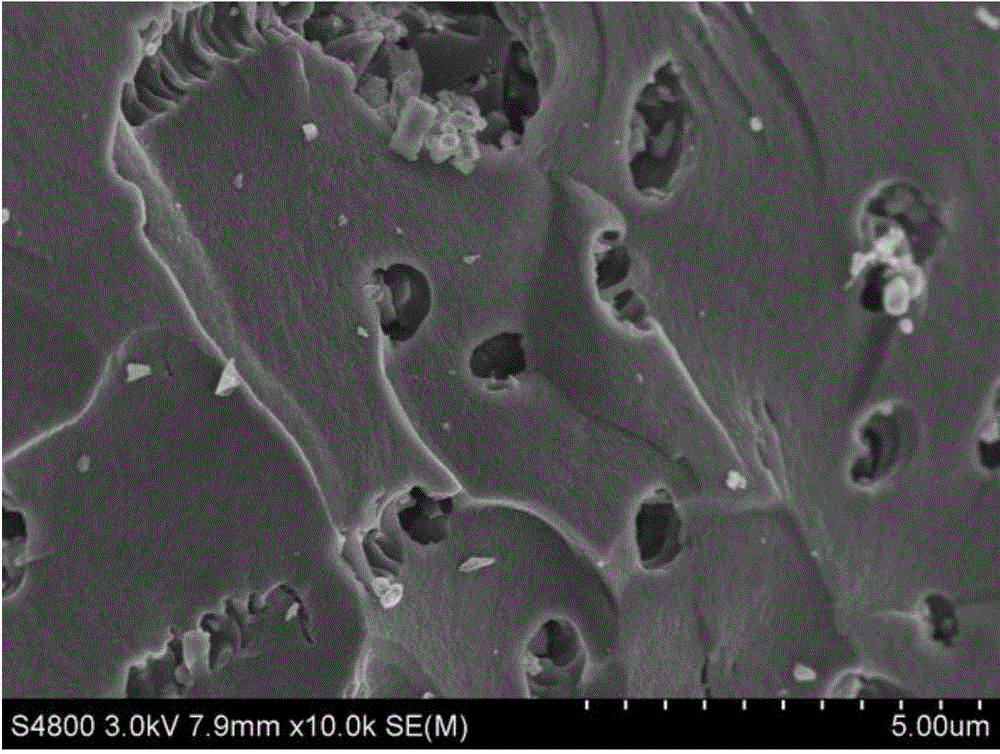

Embodiment 1

[0051] 2.5 kg each of the selected walnut shells, apricot shells and coconut shells were placed in a nitrogen-filled box furnace, and carbonized at 350 ° C for 2 hours. After the carbonized material is cooled, use a planetary ball mill to grind to a particle size (D50) of 15 μm, then mix it with sodium hydroxide particles at a ratio of 1:1 (mass ratio), and then place it in a nitrogen-filled box furnace at 650 ° C Activate for 1 hour. After the activated product is immediately injected with water and washed twice, use a mixed acid of hydrochloric acid and sulfuric acid, heat to 80°C to remove impurities for 5 hours, wash with water until neutral, then dry at 250°C under the protection of nitrogen, and sinter at 760°C to obtain the activated carbon product.

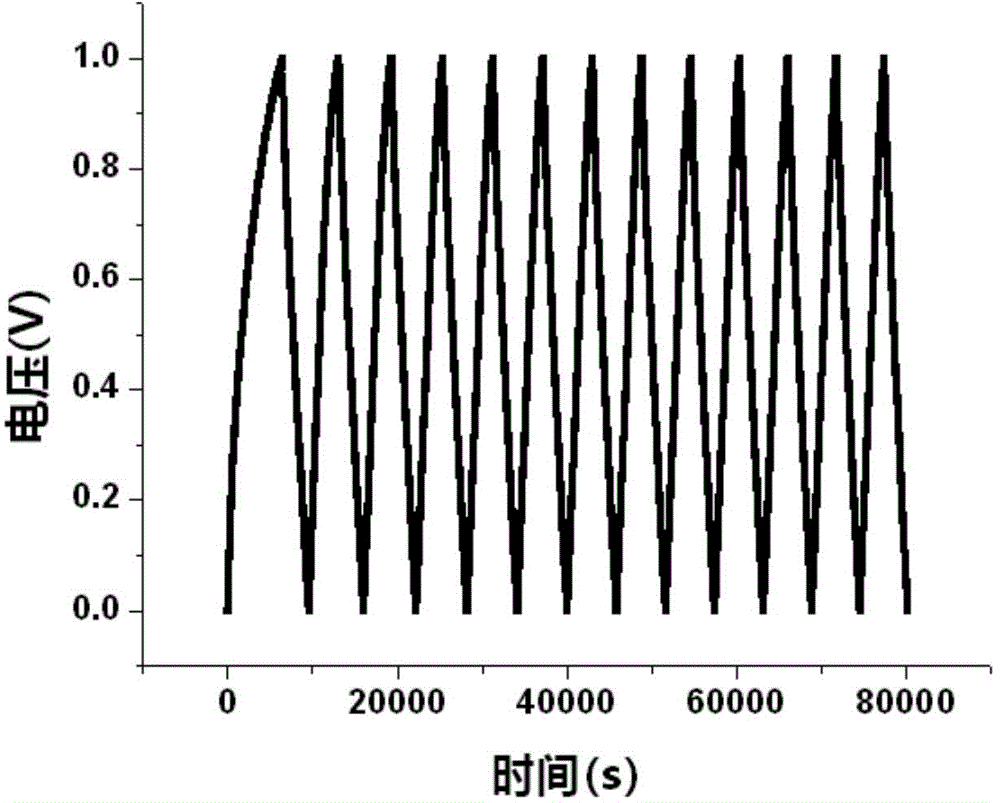

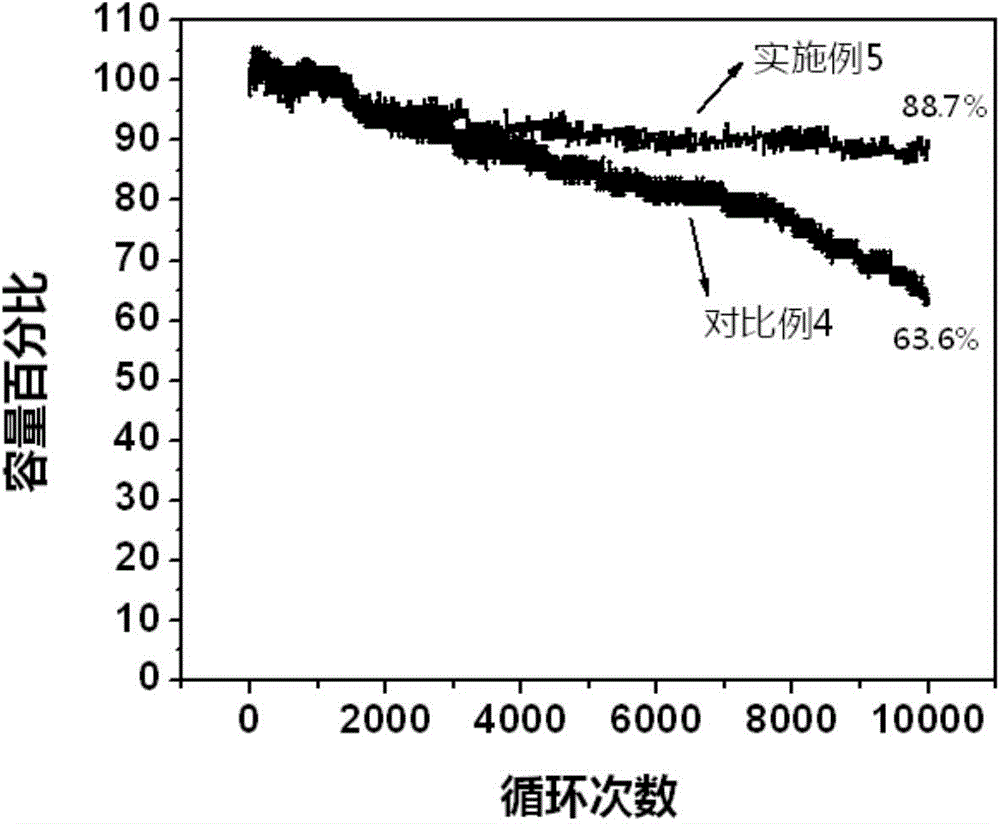

[0052] The activated carbon is prepared into a supercapacitor, wherein the water-based supercapacitor is mixed with reference to the mass ratio of activated carbon: carbon black conductive agent (SP): binder polytetrafluor...

Embodiment 2

[0056] 2.5 kg each of the selected walnut shells, apricot shells and coconut shells were placed in a nitrogen-filled box furnace, and carbonized at 350 ° C for 2 hours. After the carbonized material is cooled, use a planetary ball mill to grind to a particle size (D50) of 15 μm, then mix it with sodium hydroxide particles at a ratio of 1:1 (mass ratio), and then place it in a nitrogen-filled box furnace at 550 ° C Activate for 1 hour. After the activated product is immediately injected with water and washed twice, use a mixed acid of hydrochloric acid and sulfuric acid, heat to 80°C to remove impurities for 5 hours, wash with water until neutral, then dry at 250°C under the protection of nitrogen, and sinter at 760°C to obtain the activated carbon product.

Embodiment 3

[0065] 2.5 kg of the selected coconut shells were placed in a nitrogen-filled box furnace and carbonized at 390° C. for 1 hour. After the carbonized material is cooled, crush it to 0.5-5mm with a pulverizer, mix it with sodium hydroxide at a ratio of 1:2, place it in a nitrogen-filled box furnace, and activate it at 650°C for 1 hour. After the activated product is immediately injected with water and washed twice, take 1 times the weight of 37% hydrochloric acid and 1 times the weight of 98% concentrated sulfuric acid, heat it to 80°C to remove impurities for 5 hours, wash it with water until neutral, and then store it at 250°C under nitrogen protection. Drying, sintering at 850°C to obtain activated carbon products, that is, activated carbon products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com