Preparation method of benzyl acetate

A technology of benzyl acetate and sodium acetate, applied in the field of benzyl acetate preparation, can solve problems such as affecting the aroma of benzyl acetate, side reactions, etc., and achieve the effects of improving reaction yield and conversion rate, pure aroma and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

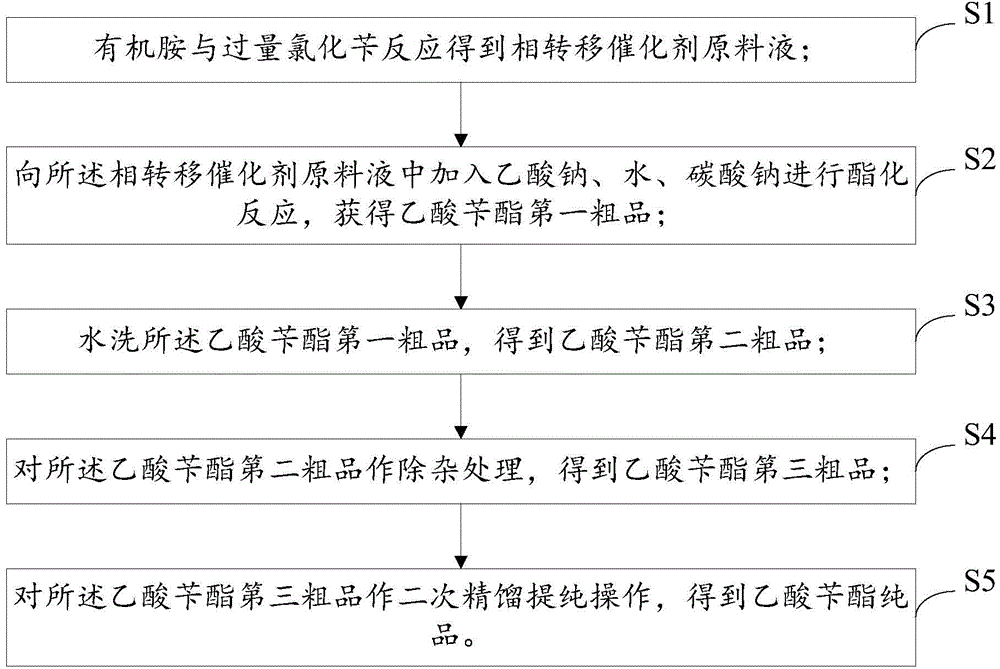

[0030] see figure 1 , is a flowchart of the preparation method of benzyl acetate described in one embodiment of the present invention. The method comprises the steps of:

[0031] S1, the organic amine reacts with excess benzyl chloride to obtain a phase transfer catalyst raw material solution;

[0032] The reaction conditions are: react at 60-90°C for 15-60 minutes, and the molar ratio of benzyl chloride to organic amine is 1:0.01-0.04. And, the organic amine is dimethylamine, trimethylamine, ethylamine.

[0033] S2. Adding sodium acetate, water, and sodium carbonate to the phase transfer catalyst raw material solution for esterification to obtain the first crude product of benzyl acetate;

[0034] The mol ratio of sodium acetate, water, sodium carbonate in the described esterification reaction is 1.05-1.25:0.4-0.5:0.01-0.03; The mass ratio of each reactant added in the described benzyl chloride and esterification reaction is 1: 1.05-1.25:0.4-0.5:0.01-0.03. The temperatur...

no. 1 example

[0050] Weigh 300g of benzyl chloride and 6g of ethylamine into the reactor, keep the temperature at 85°C, stir and react for 20 minutes, put 235g of anhydrous sodium acetate, 17g of water, and 4g of sodium carbonate into the reactor, raise the temperature to 120°C, and stir for 2.5 Hour. The first crude product of benzyl acetate was obtained after the reaction was completed, and the second crude product of benzyl acetate was obtained by washing with water.

[0051]In the second crude product of benzyl acetate of 346g, add 103.8g mass fraction and be 5% sodium carbonate aqueous solution, react at 120 ℃ for 1 hour, separate layers to obtain the organic phase; then add 173g saturated aqueous sodium bisulfite solution in the organic phase The reaction was stirred at room temperature for 1 hour, and the layers were separated to obtain the upper organic layer. Stir and react the organic layer with 14g acetic acid and 4g cationic resin at 80°C for 1.5 hours, filter, the obtained fil...

no. 2 example

[0054] Weigh 400g of benzyl chloride and 8g of dimethylamine into the reaction kettle, keep the temperature at 75°C, stir and react for 30 minutes, put 300g of anhydrous sodium acetate, 20g of water, and 4g of sodium carbonate into the reaction kettle, raise the temperature to 110°C, and stir for reaction 3 hours. The first crude product of benzyl acetate was obtained after the reaction was completed, and the second crude product of benzyl acetate was obtained by washing with water.

[0055] In the second crude product of benzyl acetate of 453, adding 182.8g mass fraction is 5% aqueous sodium carbonate solution, reacted for 1 hour at 120°C, and layered to obtain the upper organic phase; then add 453g saturated aqueous sodium metabisulfite solution in the organic phase The reaction was stirred at room temperature for 1 hour, and the layers were separated to obtain the upper organic layer. Stir and react the organic layer with 28g of acetic acid and 10g of cation exchange resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com