High-temperature-resistant crosslinking acid liquor system as well as preparation method thereof

A cross-linking acid and system technology, applied in chemical instruments and methods, mining fluids, earth-moving drilling, etc., can solve the problems of poor high temperature resistance, high cost, and large amount of cross-linking agent in the cross-linked acid system. Improve stable cross-linking performance and temperature resistance, low cost, stable release effect

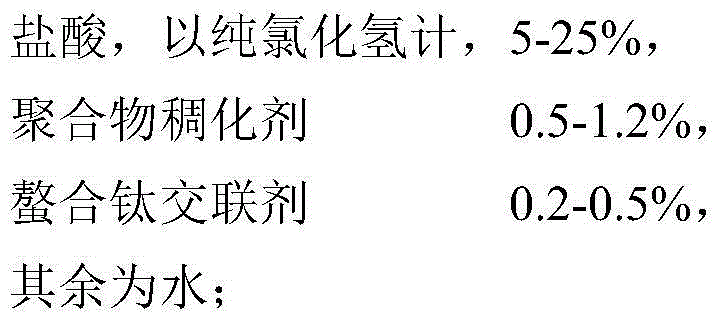

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

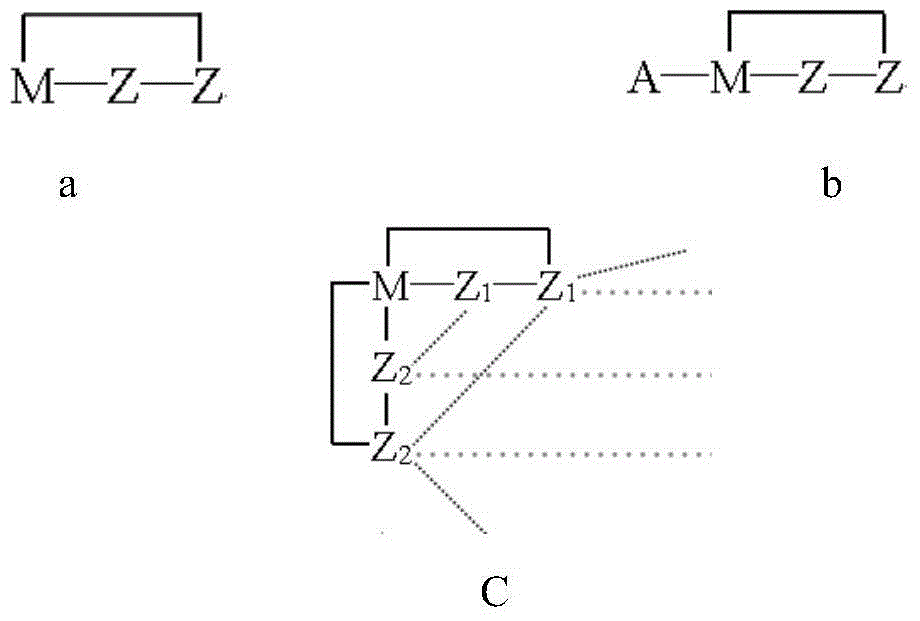

Method used

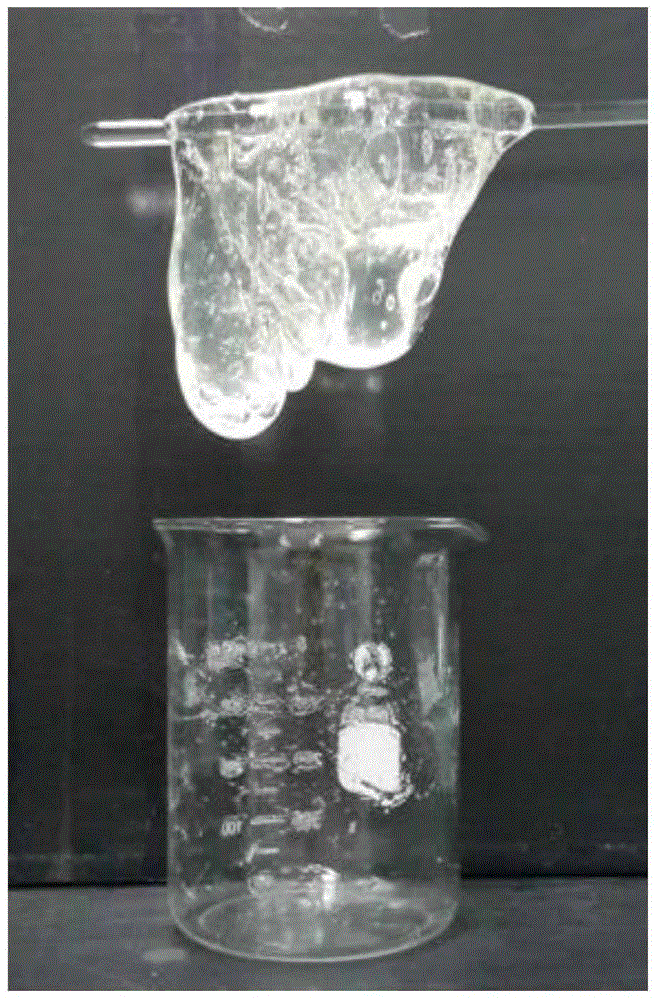

Image

Examples

Embodiment 1

[0041] Embodiment 1: the synthesis (1) of polymer thickener

[0042] Add 23g of acrylamide monomer, 17g of methacryloyloxyethyltrimethylammonium chloride, 3g of urea, and 57g of deionized water into a flask equipped with a stirrer and a thermometer, shake evenly to make the components fully miscible, Put it into ice water to cool, start nitrogen, add 0.003g polyethylene glycol diacrylate and 0.04g K after 45min 2 S 2 o 8 -NaHSO 3 After the addition, the nitrogen flow was stopped, the container was taken out from the water bath and the lid was closed, and the reaction was allowed to stand at room temperature for 8 hours. Precipitate and wash the synthesized copolymer with absolute ethanol, then suction filter to obtain a solid reactant, put it in a vacuum drying oven and dry it at low temperature (40°C) for 24 hours to obtain a thickener, and obtain the desired acrylamide-methacrylic acid Acyloxyethyltrimethylammonium chloride copolymer (molecular weight 8 million-12 millio...

Embodiment 2

[0044] Embodiment 2: the synthesis (2) of polymer thickener

[0045] Add 23.5g of acrylamide monomer, 16.5g of methacryloyloxyethyltrimethylammonium chloride, 4g of urea, and 56.5g of deionized water into a flask equipped with a stirrer and a thermometer, shake evenly to make each component fully Miscible, put into ice water to cool, start nitrogen, add 0.004g polyethylene glycol diacrylate and 0.05g K after 40min 2 S 2 o 8 -NaHSO 3 After the addition, the nitrogen flow was stopped, the container was taken out from the water bath and the lid was closed, and the reaction was allowed to stand at room temperature for 9 hours. Precipitate and wash the synthesized copolymer with absolute ethanol, then suction filter to obtain a solid reactant, put it in a vacuum drying oven and dry it at low temperature (38°C) for 24 hours to obtain a thickener, and obtain the desired acrylamide-methacrylic acid Acyloxyethyltrimethylammonium chloride copolymer (molecular weight 10 million-11 mi...

Embodiment 3

[0047] Embodiment 3: the synthesis (3) of polymer thickener

[0048] Add 24g of acrylamide monomer, 16g of methacryloyloxyethyltrimethylammonium chloride, 3.5g of urea, and 56g of deionized water into a container with a rubber stopper, shake evenly to make the components fully miscible, and put Cool in ice water, start nitrogen, add 0.005g polyethylene glycol diacrylate and 0.06g K after 35min 2 S 2 o 8 -NaHSO 3 After the addition, the nitrogen flow was stopped, the container was taken out from the water bath and the lid was closed, and the reaction was allowed to stand at room temperature for 9 hours. Precipitate and wash the synthesized copolymer with absolute ethanol, then suction filter to obtain a solid reactant, put it in a vacuum drying oven and dry it at low temperature (35°C) for 24 hours, and finally pulverize it with a pulverizer to obtain a powdery thickener. Obtain required acrylamide-methacryloxyethyltrimethylammonium chloride copolymer (molecular weight 8,00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com