Chromium-free passivation solution as well as preparation and using methods thereof

A chromium-free passivation, solution technology, applied in the direction of metal material coating process, can solve the problems of large porosity of the passivation layer, unfavorable production and use, causing suspension and other problems, and achieves fast passivation treatment speed and strong adhesion. , The effect of bath stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0041] Examples 1-12 respectively provide the composition of the chromium-free passivation solution of the present invention, as shown in Table 1 and Table 2, wherein, the unit of the numerical value of each ingredient is g / L, and the volume of the solution is 1L.

[0042]

[0043] Table 1 embodiment 1-6 passivation solution formula composition

[0044] Example 1 2 3 4 5 6 Sodium molybdate 60 60 65 65 70 70 Sodium Tungstate 5 7 9 10 5 6 ethanol 7 5 6 3 5 4 Acetic acid 15 35 25 50 30 20 hydrogen peroxide 30 20 35 40 25 30 Disodium edetate 5 9 8 10 7 5 water margin margin margin margin margin margin

Embodiment 7-12

[0045]Table 2 embodiment 7-12 passivation solution formula composition

[0046] Example 7 8 9 10 11 12 Sodium molybdate 75 75 80 80 80 80 Sodium Tungstate 8 10 5 6 8 10 ethanol 2 7 4 2 7 5 Acetic acid 40 50 50 25 40 15 hydrogen peroxide 40 35 40 25 20 35 Disodium edetate 6 9 5 8 10 7 water margin margin margin margin margin margin

[0047] The preparation method of above embodiment 1-12 passivation solution is as follows:

[0048] (1) Dissolve disodium edetate in half the volume of required water, add sodium molybdate and sodium tungstate, dissolve completely and stir evenly to obtain a salt solution;

[0049] (2) Mix ethanol and acetic acid, stir well, then slowly add hydrogen peroxide to obtain a mixed solution;

[0050] (3) Mix the salt solution in step (1) with the mixed solution in step (2), add the remaining water to the required volume, stir well, and stir for 2 hours...

Embodiment 13

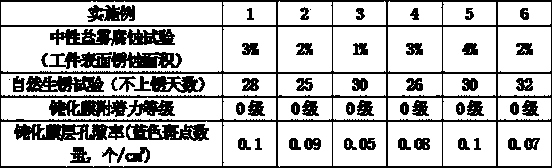

[0069] Take 100ml of the chromium-free passivation solution of Example 10, add water to dilute to 700ml and mix well to make a passivation working solution (bath solution), heat it to 60°C and maintain the temperature during the application process, and then process 100 pieces of purification After the carbon steel workpiece, the passivation time is 3 minutes, and after the treatment, it is successively baked in a 55°C hot air furnace for 15 minutes to dry to obtain a passivated workpiece; the passivation condition of each workpiece is better, and the color is consistent, respectively. 10, 30, 50, 70, and 100 pieces of workpieces were subjected to neutral salt spray corrosion test, natural rust test and measured passivation film porosity, passivation film and spray coating adhesion, all of which can reach the list in Table 5 passivation effect.

[0070] It can be seen from the above examples and comparative examples that the passivation layer of the chromium-free passivation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com