Formed foil post-processing method, electrode foil and capacitor

A technology of electrode foil and forming foil, which is applied in the field of capacitors, can solve the problems of many manufacturing processes of capacitors, affecting the qualification rate of capacitors, affecting the performance of capacitors, etc., and achieve the effect of maintaining excellent characteristics, compact structure, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

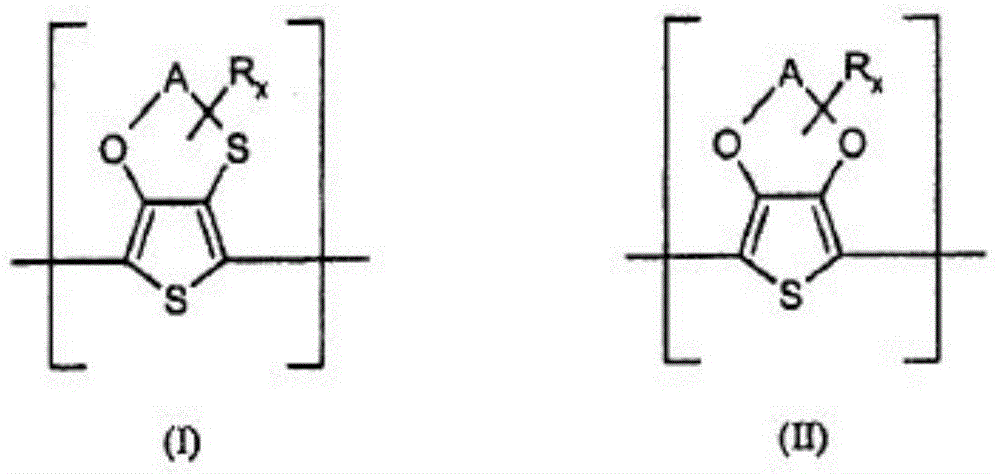

Method used

Image

Examples

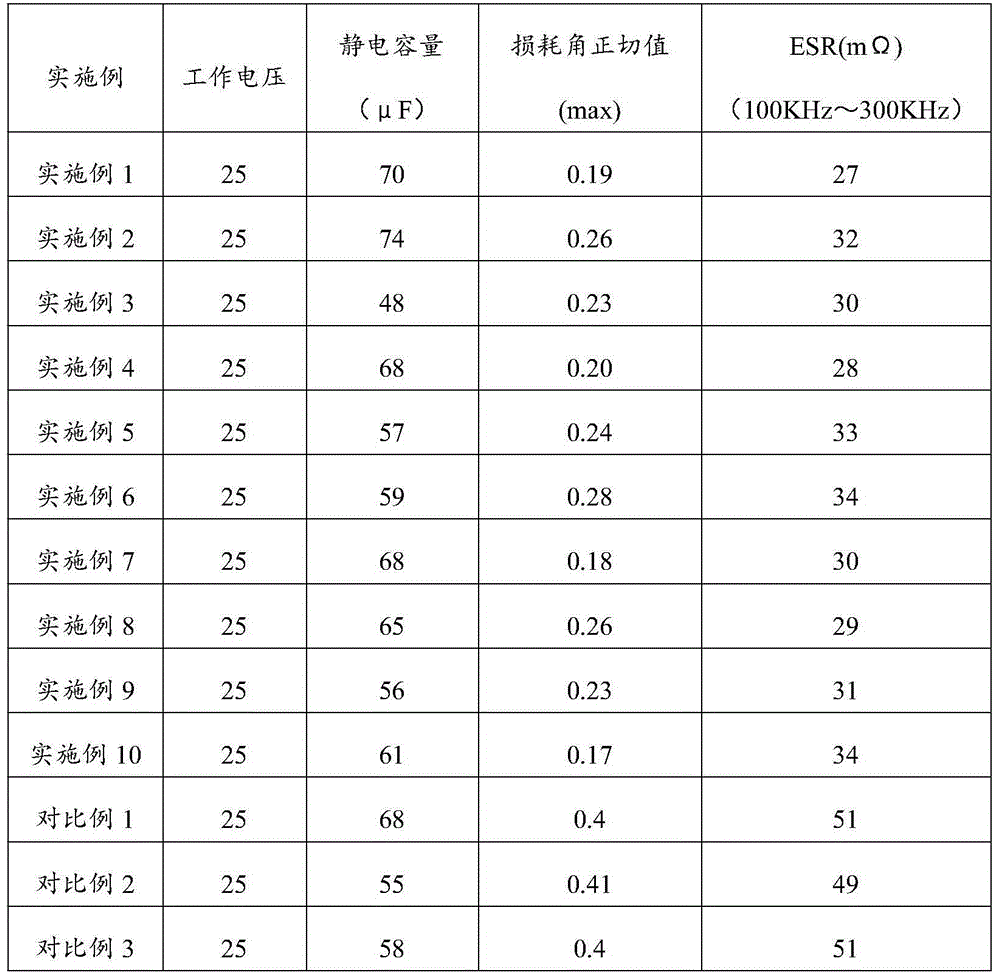

Embodiment 1

[0034] The electrolyte glue in this example is added in the following order in order: conductive polymer 50g, water-based resin 35g, wax emulsion 10g, surfactant 1g, leveling agent 1g, defoamer 1g, film forming agent 1g, adhesion promoter Add 1g of silane coupling agent, 1g of silane coupling agent, 6g of isopropanol, and 6g of pure water. Stir evenly while adding, and then coat the electrolyte glue on the surface of the metal oxide layer of the formed foil with a coating thickness of 50 μm and bake at 150°C for 5 minutes. , to obtain the electrode foil.

[0035] Then the electrode foil is assembled into a solid aluminum electrolytic capacitor according to the procedures: foil opening, riveting, winding, impregnation, and sealing. Among them, the impregnation is the step of impregnating the electrolyte in the traditional liquid capacitor. In this example, it is introduced into the preparation of solid aluminum electrolytic capacitors, which has a certain repair effect on the e...

Embodiment 2

[0038] The process and measurement methods of this example are exactly the same as those of Example 1, except that the electrolyte glue, coating thickness and baking conditions are changed, and the rest are exactly the same.

[0039] The electrolyte glue in this example is added in the following quantities: 70g of conductive polymer, 30g of water-based resin, 2g of wax emulsion, 2g of surfactant, 2g of leveling agent, 2g of defoamer, 2g of film forming agent, and 2g of adhesion promoter , silane coupling agent 2g, ethylene glycol 5g, isopropanol 5g. In this example, the coating thickness is 60 μm, and the electrode foil is obtained by baking at 120° C. for 15 minutes.

[0040] The test results of this example are also shown in Table 1.

Embodiment 3

[0042] The process and measurement methods of this example are exactly the same as those of Example 1, except that the electrolyte glue, coating thickness and baking conditions are changed, and the rest are exactly the same.

[0043] The electrolyte glue in this example was added in the following quantities: 95g of conductive polymer, 25g of water-based resin, 1g of surfactant, 1g of leveling agent, 2g of defoamer, and 2g of silane coupling agent. In this example, the coating thickness is 100 μm, and the electrode foil is obtained by baking at 150° C. for 15 minutes.

[0044] The test results of this example are also shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com