An InGaN-based blue-green light-emitting diode epitaxial structure and growth method

A technology of light-emitting diodes and epitaxial structures, applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as mismatch and large lattice, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

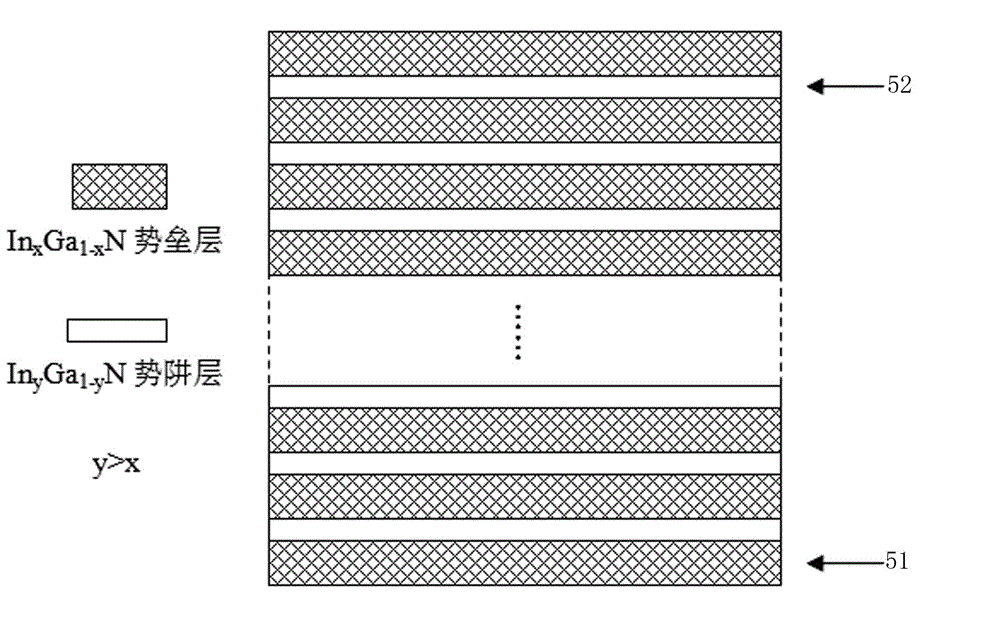

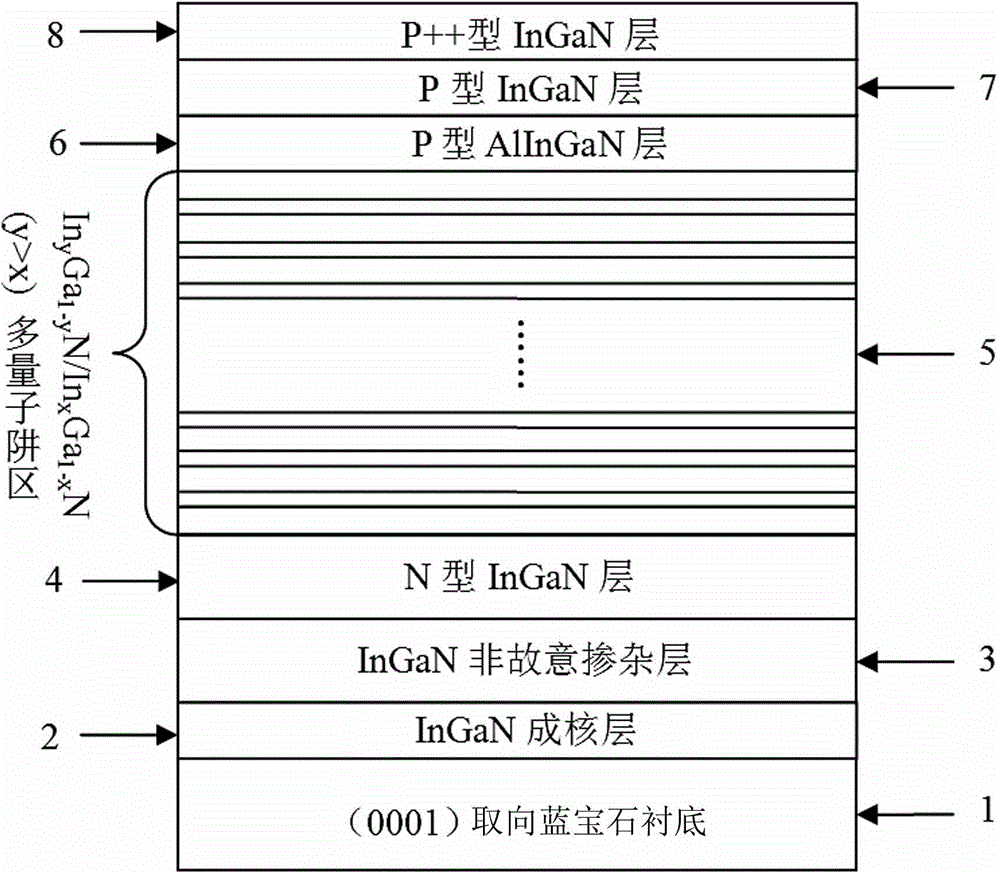

[0040] Embodiment 1 A method for growing an InGaN-based blue-green light emitting diode epitaxial structure includes the following steps:

[0041] (1) Substrate annealing treatment: annealing the (0001) surface sapphire substrate in a hydrogen atmosphere at a temperature of 1060°C, then cooling to 580°C and introducing ammonia gas, and nitriding the substrate for 6 minutes;

[0042] (2) Growing a low-temperature InGaN nucleation layer: Change the hydrogen atmosphere to a nitrogen atmosphere, turn on the gallium source TMGa and indium source TMIn, and grow a 30nm thick InGaN nucleation layer at 580°C under the condition of 50sccm hydrogen gas. The pressure is 600mbar;

[0043] (3) Growing high-temperature InGaN unintentionally doped layer: turn off TMGa and TMIn, raise the temperature to 770°C, reduce the pressure to 150mbar, turn on TMGa and TMIn again, and grow a 1 micron unintentionally doped InGaN layer;

[0044] (4) Growing an n-type InGaN layer: keeping the growth temperature and...

Embodiment 2

[0050] Embodiment 2 A growth method of an InGaN-based blue-green light emitting diode epitaxial structure includes the following steps:

[0051] (1) Substrate annealing treatment: annealing the (0001) surface sapphire substrate in a hydrogen atmosphere at a temperature of 1060°C, then cooling to 580°C and introducing ammonia gas, and nitriding the substrate for 6 minutes;

[0052] (2) Growing a low-temperature InGaN nucleation layer: Change the hydrogen atmosphere to a nitrogen atmosphere, turn on the gallium source TMGa and indium source TMIn, and grow a 30nm thick low-temperature InGaN nucleation layer at 580°C under the condition of 50sccm hydrogen gas. The growth pressure is 600 mbar.

[0053] (3) Growing high-temperature InGaN unintentionally doped layer: turn off TMGa and TMIn, raise the temperature to 770°C, reduce the pressure to 150mbar, turn on TMGa and TMIn again, and grow a 1 micron unintentionally doped InGaN layer;

[0054] (4) Growing an n-type InGaN layer: keeping the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com