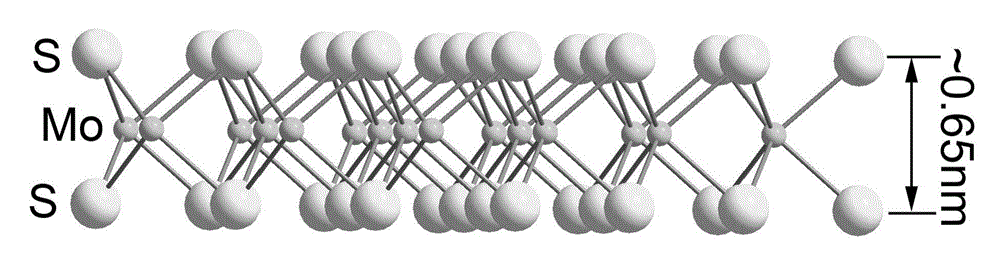

Molybdenum disulfide nano sheet and preparation method thereof

A technology of nano flakes and molybdenum disulfide, which is applied in the field of molybdenum disulfide nano flakes and its preparation, can solve the problems that the performance of electronic devices is difficult to meet the application requirements, the crystal quality of the molybdenum disulfide nano flakes is poor, and the amount of mechanical peeling is small. , to achieve the effect of easy mass production, special morphology, and uniform growth in a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

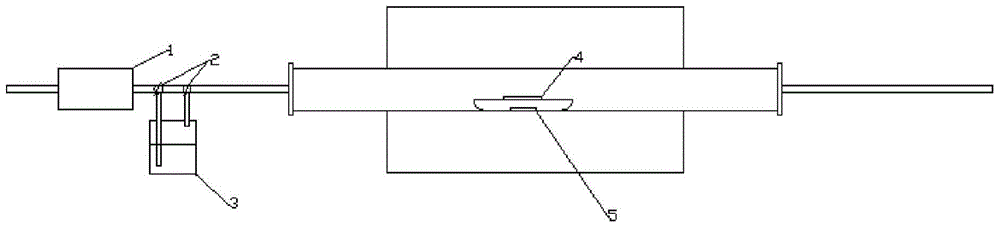

[0049] (1) Use such as figure 2 In the shown chemical vapor deposition device, the untreated molybdenum trioxide powder 5 is placed in the middle of the quartz boat as the molybdenum source, and the quartz boat is placed in the quartz tube so that the molybdenum source is located in the central area of the tube furnace. Use a vacuum pump to exhaust the air in the quartz tube, and then introduce an inert gas, and cycle like this for 3 times to exhaust the oxygen in the quartz tube as much as possible. Then continuously blow 250 sccm of inert gas into the quartz tube for 30 minutes to exhaust oxygen as much as possible. Then start heating, the inert gas flow rate is maintained at 25 sccm during the heating process, and the temperature increase rate is controlled to be 10 °C / min;

[0050] (2) When the temperature in the central area of the tube furnace reaches 720°C, the carrier gas loaded with carbon disulfide is introduced (before the quartz tube is passed into the bubble...

Embodiment 2

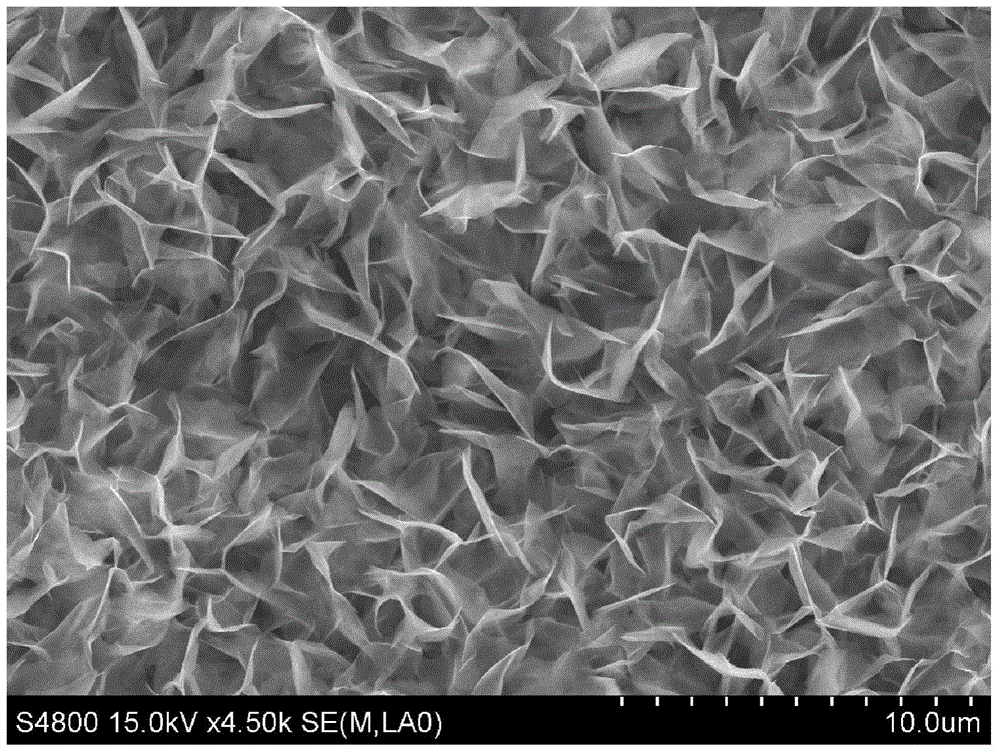

[0057] Molybdenum disulfide nanoflakes were prepared according to the method in Example 1. The difference is that when the temperature in the central area of the tube furnace reaches 750°C, the carrier gas loaded with carbon disulfide vapor is introduced at a flow rate of 250 sccm, and the tube furnace is turned off after 5 minutes of reaction. The scanning electron micrograph of the product that present embodiment obtains is as Figure 7 shown. This result is similar to the result of Example 1, and uniform molybdenum disulfide nanosheets have also grown.

Embodiment 3

[0059] Molybdenum disulfide nanoflakes were prepared according to the method in Example 1. The difference is that when the temperature in the central area of the tube furnace reaches 690°C, the carrier gas loaded with carbon disulfide vapor is introduced at a flow rate of 20 sccm, and the tube furnace is turned off after 60 minutes of reaction. The scanning electron micrograph of the product that present embodiment obtains is as Figure 8 shown. The results of this example are similar to those of Examples 1 and 2, and uniform molybdenum disulfide nanosheets were also grown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com