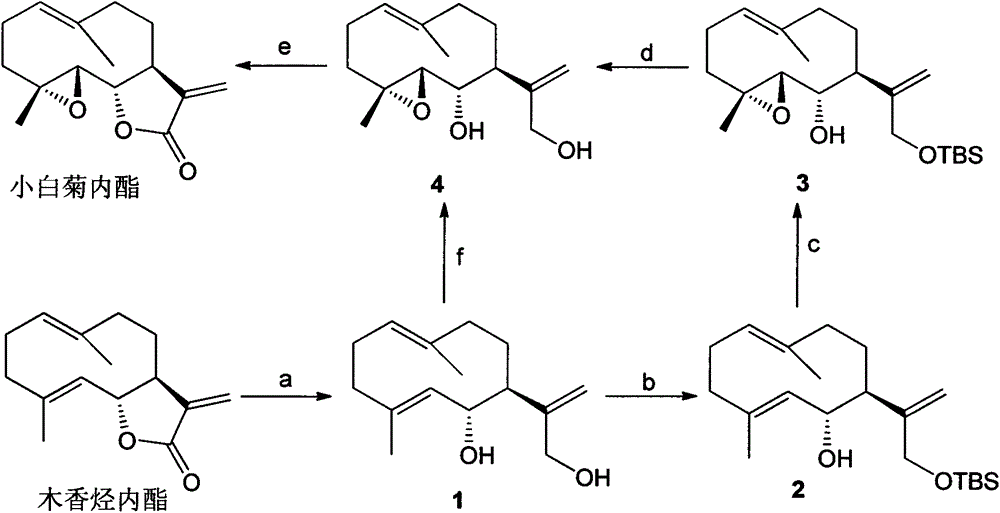

Method for preparing parthenolide by using costunolide as raw material

A kind of technology of parthenolide and woody lactone, which is applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

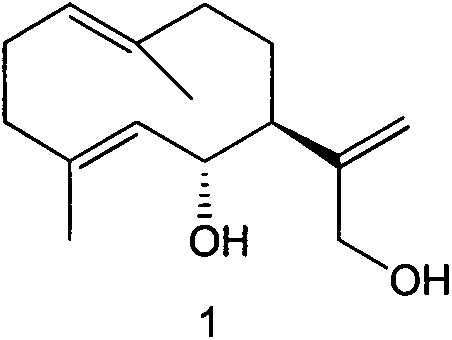

[0014] Preparation of compound 1:

[0015] Under the protection of nitrogen, dissolving coynelide (1.39g, 6mmol) in dried toluene, cooled to zero, slowly added 1M diisobutylaluminum hydride dichloromethane solution (24mL, 24mmol), after the addition was complete Stirring was continued for four hours at room temperature. After TLC detected that the reaction was substantially complete, it was quenched with 10% sodium potassium tartrate solution (10 mL), filtered a layer of diatomaceous earth, and the aqueous phase was extracted three times with ether, and the combined organic layers were washed with saturated brine. Dry over anhydrous sodium sulfate. After filtration and purification by column chromatography, compound 1 (1.11 g, 79%) was obtained.

[0016]

[0017] Molecular formula: C 15 h 24 o 2

[0018] Molecular weight: 236

[0019] Appearance: colorless oily

[0020] Spectral data:

[0021] δ 1 HNMR (400MHz, CDCl 3 )δ5.16(s, 1H), 5.01(s, 1H), 4.79(brd, J=10.4Hz...

Embodiment 2

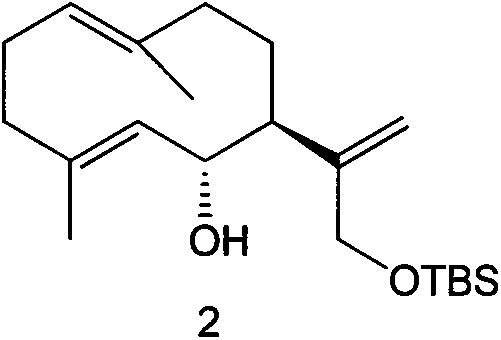

[0023] Preparation of Compound 2:

[0024] Under nitrogen protection, compound 1 (115mg, 0.487mmol), 4-dimethylaminopyridine (6mg, 0.0487mmol), triethylamine (0.12mL, 0.818mmol) were dissolved in dry dichloromethane (2.3mL), Cool to zero, add 0.54M trimethylchlorosilane dichloromethane solution (1mL, 0.54mmol), stir for 4 hours, add saturated brine (2.4mL) to terminate the reaction, and extract the aqueous layer with dichloromethane (5mL) three times, It was dried over sodium sulfate, filtered, concentrated and purified by column chromatography to obtain compound 2 (159 mg, 93%).

[0025]

[0026] Molecular formula: C 21 h 38 o 2 Si

[0027] Molecular weight: 350

[0028] Appearance: colorless oily

[0029] Spectral data:

[0030] 1 HNMR (400MHz, CDCl 3 )δ5.16(s, 1H), 5.00(s, 1H), 4.80(brd, J=10.0Hz, 1H), 4.64(brd, J=9.6Hz, 1H), 4.21-4.06(m, 3H), 2.66(s, 1H), 2.40-2.30(m1H), 2.29-2.16(m, 2H), 2.16-2.01(m, 3H), 2.01-1.92(m, 1H), 1.71-1.62(m, 5H), 1.41(s, 3H), 0.93...

Embodiment 3

[0032] Preparation of Compound 3:

[0033] method 1:

[0034] Under nitrogen protection, add 723mg activated Molecular sieves and 19 mL of dried dichloromethane. Cool to -4 degrees, add diisopropyl tartrate (60μL, 0.28mmol), stir for ten minutes, add titanium tetraisopropoxide (70μL, 0.24mmol), stir for 15 minutes, then add 3.3mol / L peroxide tert-butanol toluene solution (1.1mL, 3.63mmol), after stirring for 30 minutes, compound 2 ((817mg, 2.35mmol) was dissolved in 4mL of dried dichloromethane and added, the reaction temperature was raised to -18 degrees, Stir for 12 hours, add acetone (20mL) containing 2% water to quench the reaction, rise to room temperature and stir for 3 hours, filter a layer of diatomaceous earth, dry the filtrate with anhydrous magnesium sulfate, filter and concentrate to pass through the column to obtain compound 3 (607mg , 71%)

[0035] Method 2:

[0036] Dissolve compound 2 (220mg, 0.63mmol) in dichloromethane (15mL), add vanadyl acetylacetonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com