Resin composition for sealing semiconductor, semiconductor device with the cured product thereof and method for manufacturing semiconductor device

A resin composition and sealing technology, which can be used in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as insufficient moisture resistance, reduced adhesion of CuLF, peeling or cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0185] Hereinafter, examples and comparative examples are shown, and the present invention will be described in more detail, but the present invention is not limited to the following examples. In addition, the part in each example is a mass part.

[0186] [Example and Comparative Example]

[0187] Prepare the following components with the compositions shown in Table 1 to Table 6, mix them uniformly with a high-speed mixer, knead them uniformly with two heated rollers, cool them, and pulverize them to obtain a resin composition .

[0188] [Components (A) to (D) used in the first composition, the second composition, and the third composition]

[0189] (A) Cyanate compound

[0190] (a) Cyanate compound represented by the following formula (7) (Primaset (Primaset) PT-60, manufactured by Lonza Japan Co., Ltd., cyanoxy group equivalent: 119)

[0191] [chem 25]

[0192]

[0193] (mixture of n=0~10)

[0194] (b) Cyanate compound obtained in Synthesis Example 1 below

Synthetic example 1

[0196] 100 g of phenol compound MEH-7851SS (manufactured by Meiwa Kasei) was dissolved in 600 g of butyl acetate. The solution was cooled to about -15°C, and 32 g of gaseous cyanogen chloride was introduced. Next, 50 g of triethylamine was added dropwise with stirring over about 30 minutes while maintaining the temperature at -10°C or lower. After a further 30 minutes at the temperature, the cooling was stopped and the reaction mixture was filtered. The filtrate is then passed to an ion exchanger packed column. Next, the solvent was removed under reduced pressure at a bath temperature of 70°C, followed by removal of volatile impurities (including solvent residues, free triethylamine, di ethyl cyanamide). The obtained product was a cyanate compound represented by the following formula (8) (cyanooxy group equivalent weight: 208).

[0197] [chem 26]

[0198]

[0199] (mixture of n=0~10)

[0200] (B) Phenolic compounds

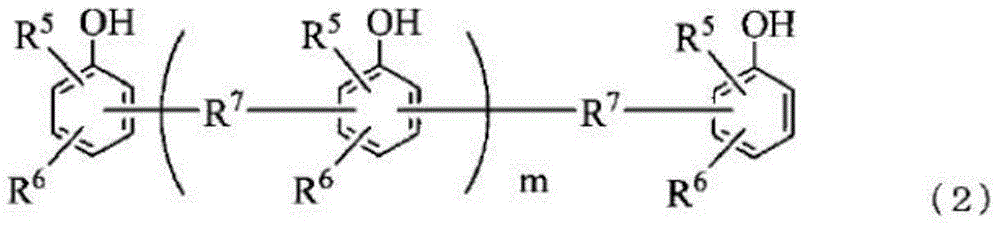

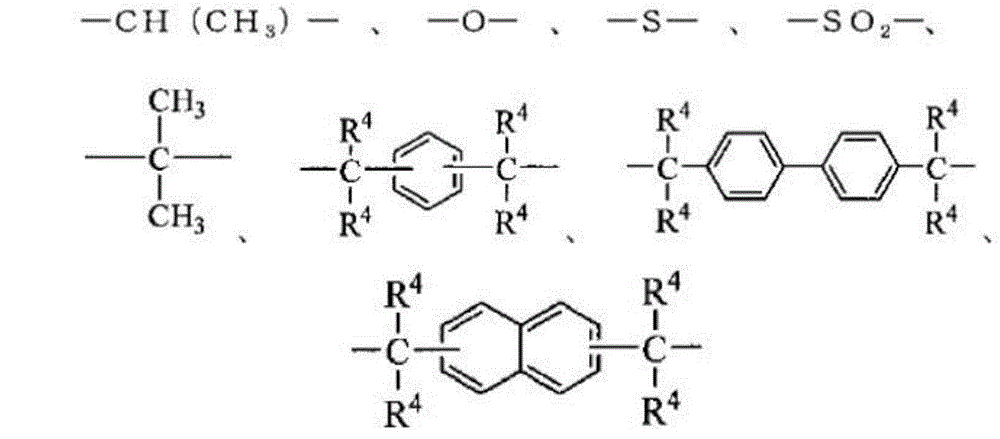

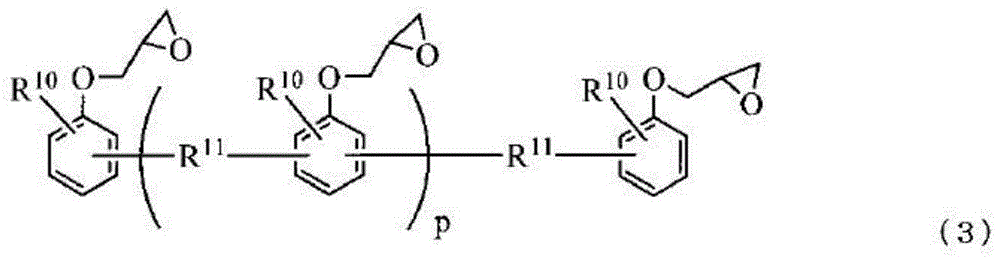

[0201] (c) A phenolic compound represented by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com