Method for producing biologic cellulose from microorganism aerosol

A technology of biological cellulose and aerosol, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as waste, low yield, and reduced fermentation efficiency, so as to expand the range of shapes and sizes and reduce production Cost, the effect of prolonging the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of mist aerosol

[0023] Use coconut water as the liquid medium, inoculate it with 8% by volume of Gluconacetobacter xylinum seed solution that has been cultivated to the logarithmic growth phase after sterilization, and then spray it together with sterile compressed air through a gas-liquid two-phase nozzle The mist aerosol is formed in the aerosol generation chamber, and the flow rate of sterile compressed air is 8 m 3 / h, the flow rate of the liquid medium is 200 ml / min. The aerosol preparation equipment can use a commercially available atomized aerosol generator, and its working principle is: most atomized aerosol generators have a nozzle, and compressed air is blown into the liquid to be atomized through an annular gap, and the air injection port The shear force between the liquid and the liquid fully disperses the liquid droplets in this annular gap to form fine aerosol particles. The preparation of the mist aerosol of the present i...

Embodiment 2

[0024] Embodiment 2: the preparation of mist aerosol

[0025] Take 10g of glucose, 10g of sucrose, 10g of yeast extract, 5g of peptone, and 2g of potassium dihydrogen phosphate, and dilute it to 1000ml with distilled water to make a liquid medium. After sterilization, inoculate the seeds of Gluconacetobacter xylinum that have been cultivated to the logarithmic growth phase Liquid 10% by volume; then spray it and sterile compressed air into the aerosol generating chamber through the gas-liquid two-phase nozzle to form a mist aerosol, the flow rate of sterile compressed air is 6 m 3 / h, the flow rate of the liquid medium is 100 ml / min. Use the same equipment as above.

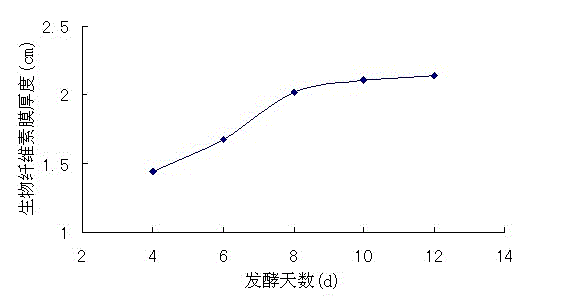

[0026]

Embodiment 3

[0027] Embodiment 3: the preparation of mist aerosol

[0028] Get 5g of glucose, 15g of fructose, 8g of ammonium sulfate, 10g of peptone, and 1g of magnesium chloride, and dilute to 1000ml with distilled water to make a liquid medium, and inoculate 12% by volume of Acetobacter xylinum seed solution that has been cultivated to the logarithmic growth phase after sterilization; Then spray it and sterile compressed air into the aerosol generating chamber through the gas-liquid two-phase nozzle to form a mist aerosol. The flow rate of the sterile compressed air is 2 m 3 / h, the flow rate of the liquid medium is 50 ml / min.

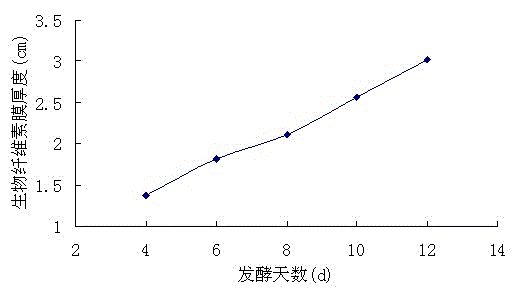

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com