A kind of preparation method of compound micropill capsule and the prepared compound micropill capsule

A technology of teriflunomide compound pellets and capsules is applied in the preparation of compound pellets and capsules, and the field of compound pellets and capsules can solve the problems of inconvenience in taking, high production cost and high medical cost, and achieve convenient administration and low production and medical cost. , the effect of reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of dimethyl fumarate-teriflunomide compound pellet capsule

[0027] 1. Preparation of drug-loaded pills

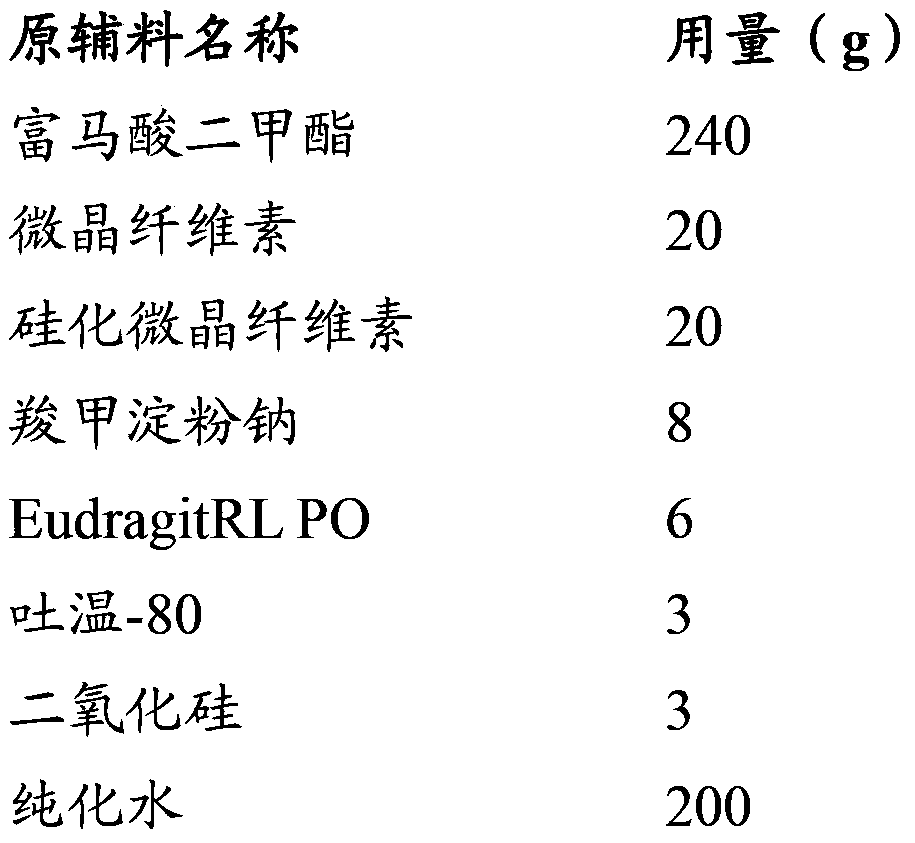

[0028] (1) Prescription (1000 capsules)

[0029]

[0030] (2) Preparation

[0031] Mix the recipe amount of dimethyl fumarate, microcrystalline cellulose, sodium starch glycolate, silicified microcrystalline cellulose, Tween-80, silicon dioxide and purified water, and add EudragitRL PO binder Solution, wet granulation, put the wet granules into a rotary extruder, the extruded strips are pelletized in a centrifugal spheronizer, the extrusion speed is 70rpm, the screen diameter is 1.0mm, the spheronizer speed is 300rpm, and the spheronization time For 5 to 7 minutes, the extrusion spheronizer was a WL-350 extrusion spheronizer from Zhejiang Xiaolun Pharmaceutical Co., Ltd. After making pellets, it was put into an oven for drying at 35°C.

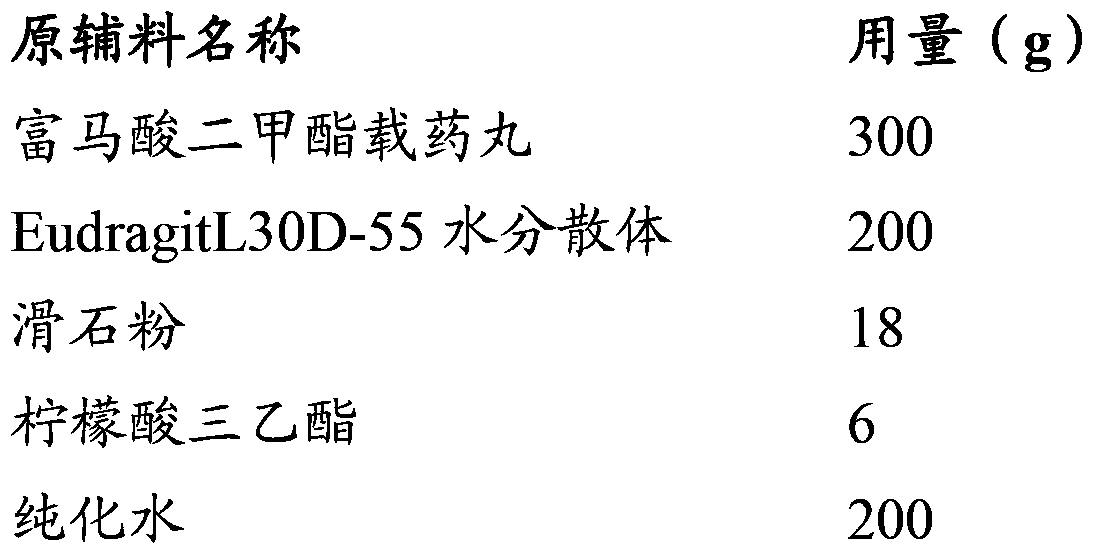

[0032] 2. Preparation of delayed release layer coating

[0033] (1) Prescription (coating wei...

Embodiment 2

[0043] Embodiment 2: the preparation of dimethyl fumarate-teriflunomide compound pellet capsule

[0044] 1. Preparation of drug-loaded pills

[0045] (1) Prescription (1000 capsules)

[0046]

[0047] (2) Preparation

[0048] Mix the recipe amount of dimethyl fumarate, microcrystalline cellulose, sodium starch glycolate, silicified microcrystalline cellulose, Tween-80, silicon dioxide and purified water, and add EudragitRL PO binder Solution, wet granulation, put the wet granules into a rotary extruder, the extruded strips are pelletized in a centrifugal spheronizer, the extrusion speed is 70rpm, the screen diameter is 1.0mm, the spheronizer speed is 300rpm, and the spheronization time For 5 to 7 minutes, the extrusion spheronizer was a WL-350 extrusion spheronizer from Zhejiang Xiaolun Pharmaceutical Co., Ltd. After making pellets, it was put into an oven for drying at 35°C.

[0049] 2. Preparation of delayed release layer coating

[0050] (1) Prescription

[0051] ...

Embodiment 3

[0061] Embodiment 3: the preparation of dimethyl fumarate-teriflunomide compound pellet capsule

[0062] 1. Preparation of drug-loaded pills

[0063] (1) Prescription (1000 capsules)

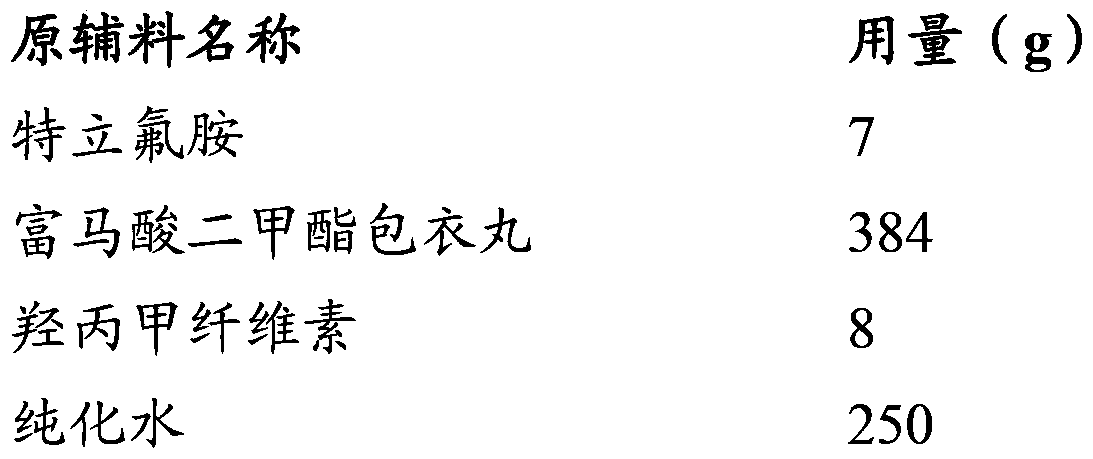

[0064]

[0065]

[0066] (2) Preparation

[0067] Mix the recipe amount of dimethyl fumarate, microcrystalline cellulose, sodium starch glycolate, silicified microcrystalline cellulose, Tween-80, silicon dioxide and purified water, and add EudragitRL PO binder Solution, wet granulation, put the wet granules into a rotary extruder, the extruded strips are pelletized in a centrifugal spheronizer, the extrusion speed is 70rpm, the screen diameter is 1.0mm, the spheronizer speed is 300rpm, and the spheronization time For 5 to 7 minutes, the extrusion spheronizer was a WL-350 extrusion spheronizer from Zhejiang Xiaolun Pharmaceutical Co., Ltd. After making pellets, it was put into an oven for drying at 35°C.

[0068] 2. Preparation of delayed release layer coating

[0069] (1) Prescription ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com