Method for denitration by catalytic direct decomposition of NO with perovskite type catalyst

A perovskite type, catalyst technology, applied in the field of catalytic decomposition of NO denitration, can solve the problems of complex removal process, low NO removal rate, etc., and achieve high removal efficiency, convenient operation and easy control, and strong oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

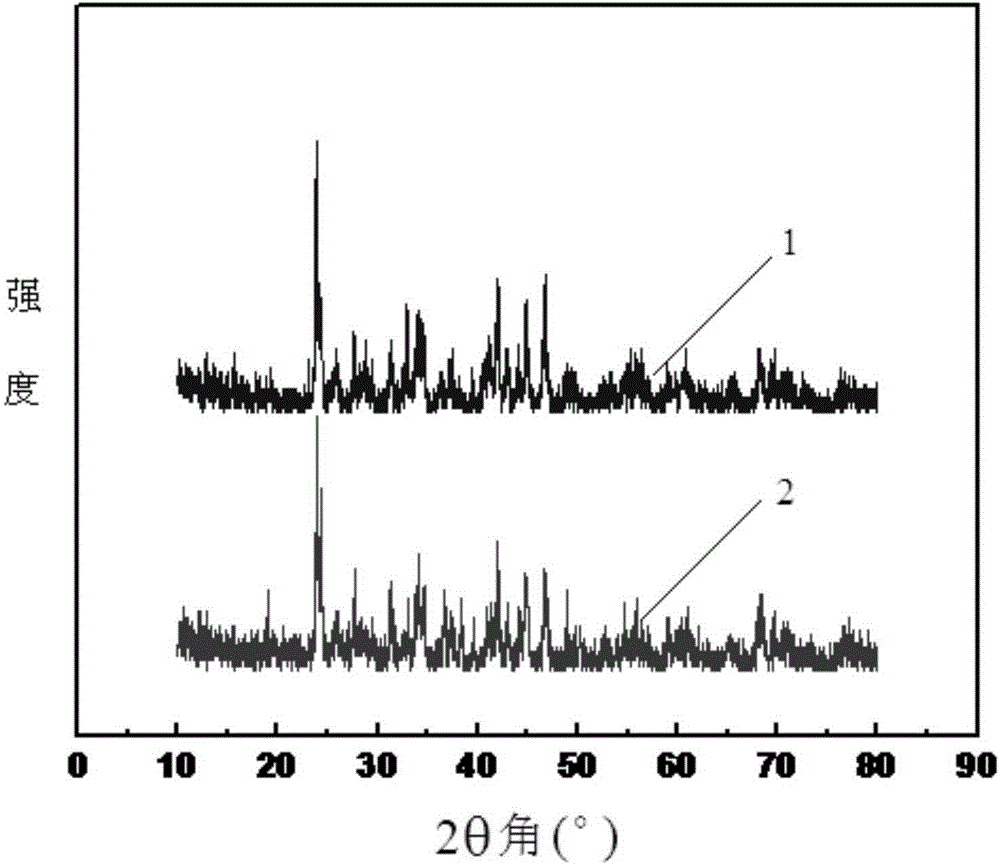

Embodiment 1

[0021] According to the stoichiometric ratio (BaMn 1-x Mg x O 3 , X = 0, 0.1, 0.2, 0.3, 0.4) A certain amount of precursor salt was dissolved in 120 ml of distilled water, ultrasonicated for 15 minutes, heated to 50° C., and stirred for 15 minutes. Add appropriate amount of citric acid and ethylene glycol (the ratio of metal salt cation is 1.25), stir for 0.5h, then heat to 80°C and stir for 2h. Place it in an oven at 120°C for 12h, put it in a muffle furnace at 400°C for 2h, and then 700°C for 4h to obtain the corresponding catalyst powder.

Embodiment 2

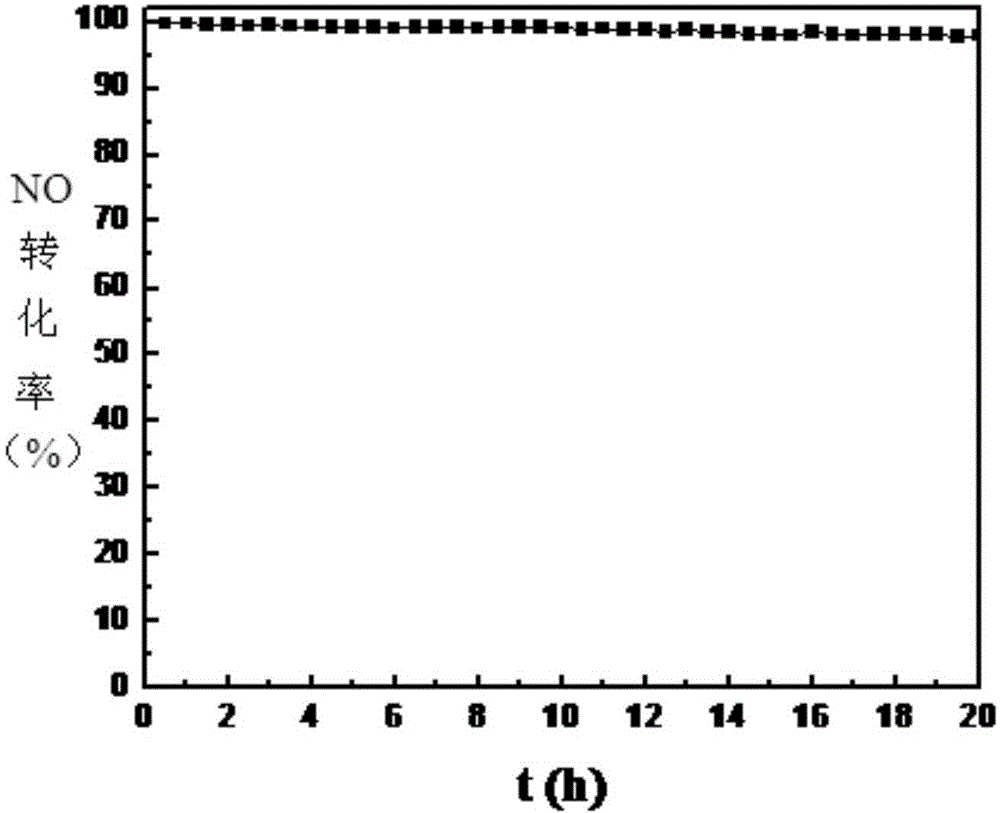

[0023] The method of the present invention includes filling a catalyst in the reaction tube of a microwave catalytic reactor device to form a microwave catalytic reaction bed, and the exhaust gas to be treated undergoes a gas-solid phase reaction when passing through the microwave catalytic reaction bed for denitration treatment; the catalyst is BaMn 1-x Mg x O 3 (x=0,0.1,0.2,0.3,0.4); The catalyst is filled in the reaction tube of the microwave catalytic reactor device. When the exhaust gas to be treated passes through the microwave catalytic reaction bed, the NO in the gas directly decomposes and reacts to generate an environment Friendly N 2 And O 2 , In order to achieve the purpose of direct denitration. The temperature of the direct catalytic decomposition reaction is 100°C to 400°C, preferably 200-300°C; the pressure of the direct catalytic decomposition reaction is normal pressure or slightly higher than atmospheric pressure.

[0024] In this embodiment, the waste gas to be...

Embodiment 3

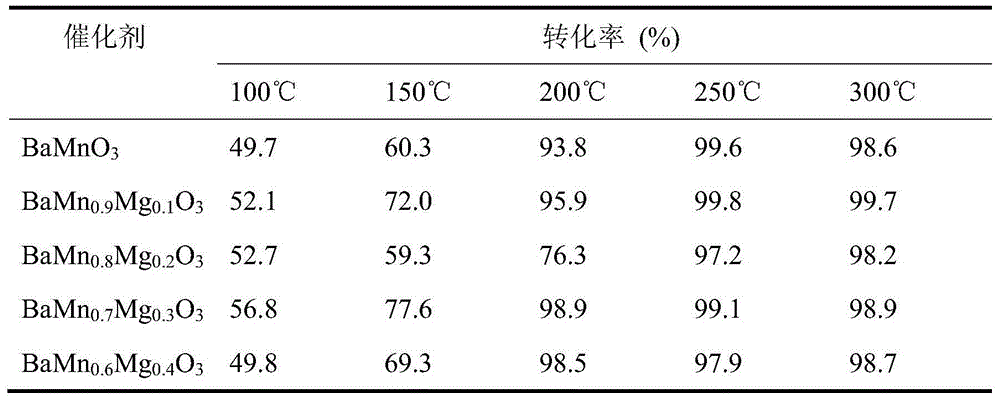

[0031] It is basically the same as Example 2, except that the oxygen content in the intake air is changed to 0-10%.

[0032] The packed catalyst is BaMn 1-x Mg x O 3 , The filling amount of the catalyst is 2g, and the mesh number is 20-60 mesh. The intake NO concentration is 1000 ppm, the oxygen content in the intake is changed to 0%, 5%, 7.5%, 10%, the residence time of the gas in the microwave catalytic reaction bed is 1s, and the reaction pressure is normal pressure. The microwave power was adjusted to maintain the temperature of the catalyst bed at 250°C, and the oxidation resistance of the catalyst in the microwave catalytic decomposition of NO was investigated. The results are shown in Table 2.

[0033] Table 2

[0034]

[0035]

[0036] Among them, the imported NO content is 1000ppm. When oxygen is present, almost all NO is converted into safe N 2 , The NO conversion rate at 250°C is above 97.2%, indicating that the perovskite catalyst has good oxidation resistance in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com