Activated carbon fiber modification method, water treatment filter device and application of water treatment filter device

An activated carbon fiber and water treatment technology, applied in the field of water treatment and filler, can solve the problems of inability to use the environment for a long time, insufficient strength and toughness, easy to fall off and easy to block, etc., to achieve good water purification effect, enhanced microbial affinity, environmental protection friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Boil and soak the PAN-based carbon fiber filaments in deionized water for 2.5 hours and keep stirring; then move to room temperature deionized water and soak for 3 hours and keep stirring, and then wash with a large amount of deionized water to remove impurities. After cleaning, the PAN-based carbon fiber filaments Dry at 120°C for 10 hours to obtain the pretreated activated carbon fiber filaments; dilute analytically pure nitric acid with a mass fraction of 65% with deionized water to obtain a nitric acid solution with a concentration of 0.15mol / L, and then prepare the obtained pretreated Immerse activated carbon fiber filaments in 0.15mol / L nitric acid solution, add ammonium dihydrogen phosphate according to the molar concentration ratio of ammonium dihydrogen phosphate (99% in mass concentration, analytically pure) to nitric acid and stir, and soak for 12 hours Take it out, heat it and dry it for 10 hours, then calcine it under the condition of passing through N2 for 0...

Embodiment 2

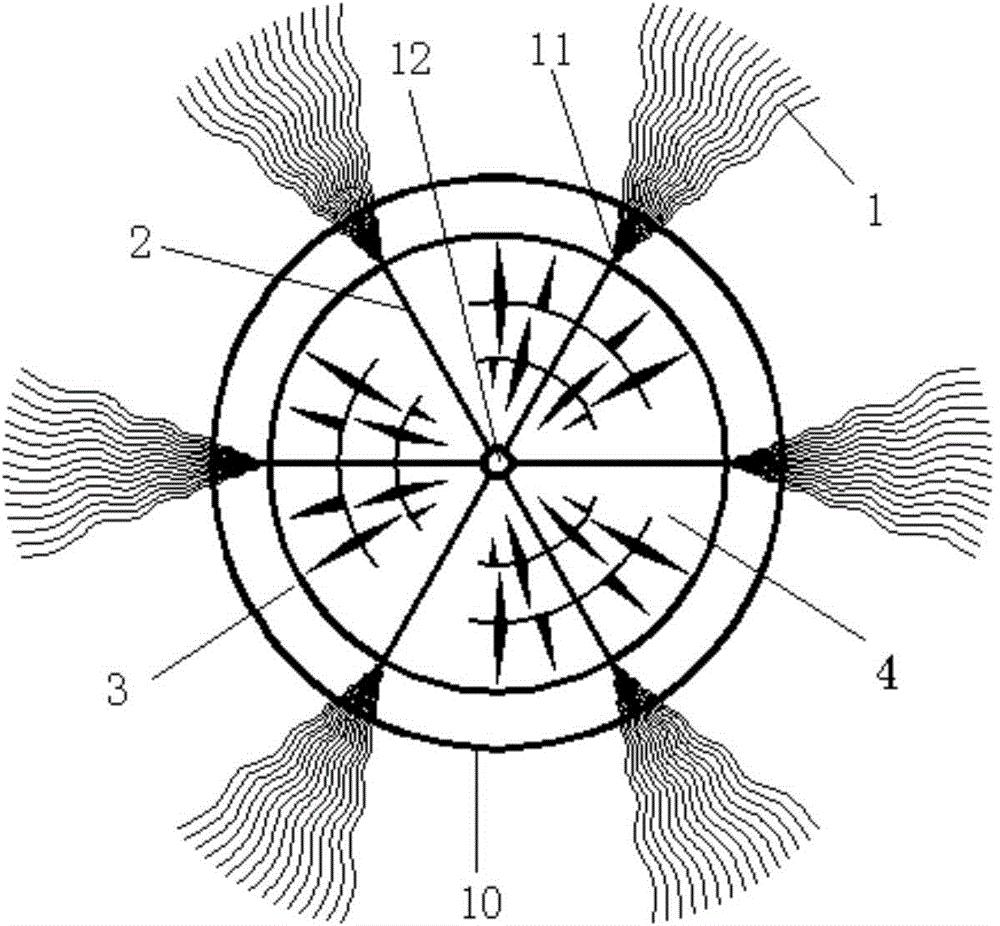

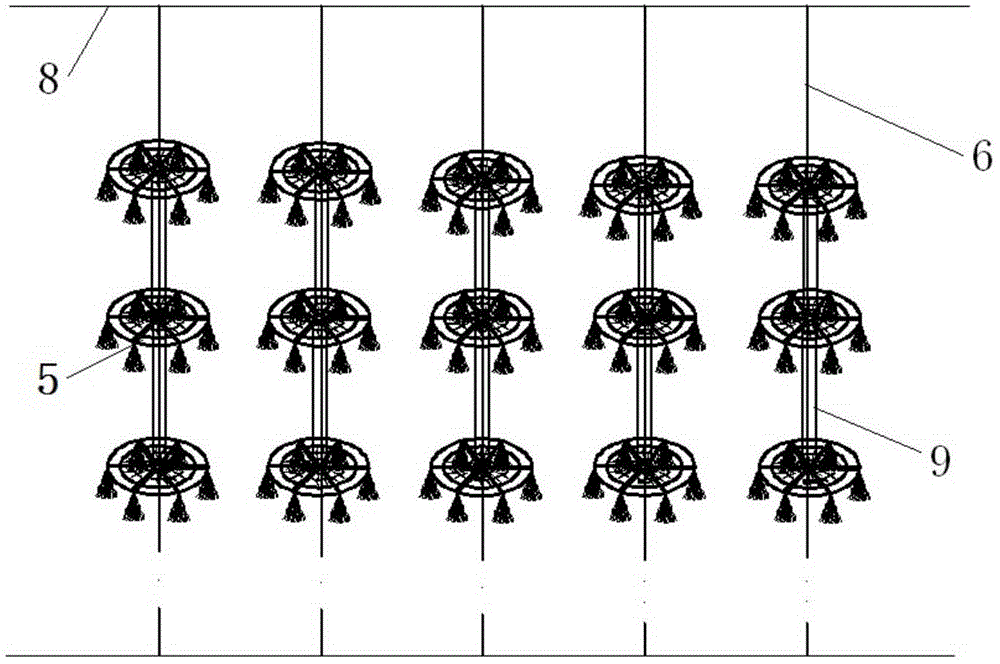

[0041] Such as figure 1 with figure 2 As shown, a water treatment packing device includes a packing monomer 5, a steel wire rope 6, a fixed bracket 8 and a hard plastic tube 9, one end of the steel wire rope 6 is fixed on the fixed bracket 8, and the filler monomer 5 is connected in series on the steel wire rope 6. Ten filler monomers 5 are connected in series on each steel wire rope 6, and each two filler monomers 5 are separated by a hard plastic tube 9; the filler monomer 5 is composed of a water treatment filler 1 and an annular carrier 4, and the water The treatment filler 1 is the modified PAN-based carbon fiber filament in Example 1, with a length of 10 cm, and one end folded in half is clamped inside the annular carrier 4 and fixed; the manufacturing material of the annular carrier 4 is POM plastic, made of Composed of two discs, the central part of the disc is provided with a central disc 3, and the outer side is a ring 10 with a diameter of 12 cm. The ring 10 is pr...

Embodiment 3

[0044] The modification method of PAN base carbon fiber silk is the same as embodiment 1, and difference is: the immersion time in the step (b) is 2h; The calcination temperature in the step (f) is 570 ℃, and the calcination time is 0.5h, and the holding temperature is 92° C.; the concentration of the nitric acid solution in step (e) is 0.20 mol / L, obtained by diluting the analytical grade nitric acid with a mass fraction of 68% with deionized water.

[0045] The specific surface area of the PAN-based carbon fiber modified by the method in this example increases by about 0.9 times on average, and the microbial affinity is enhanced, which can better provide conditions for the growth and reproduction of various microorganisms, and the film-hanging rate and uniformity The amount of film hanging increased by 36% and 42% respectively, which can better absorb and absorb dissolved and suspended pollutants in water.

[0046] The above-mentioned modified PAN-based carbon fiber filame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com