Iron-based catalyst and preparation method thereof

A technology of catalyst and catalyst carrier, applied in the field of coal chemical industry, can solve problems such as easy agglomeration of iron-based catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

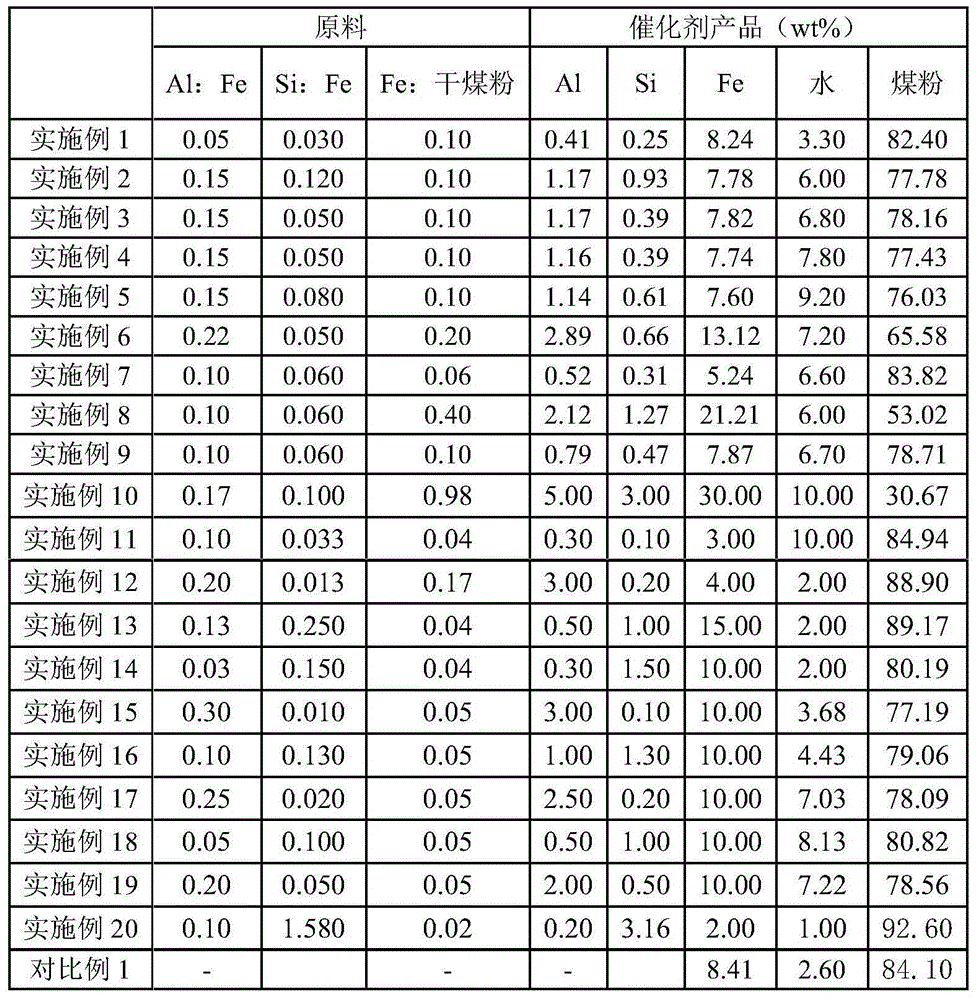

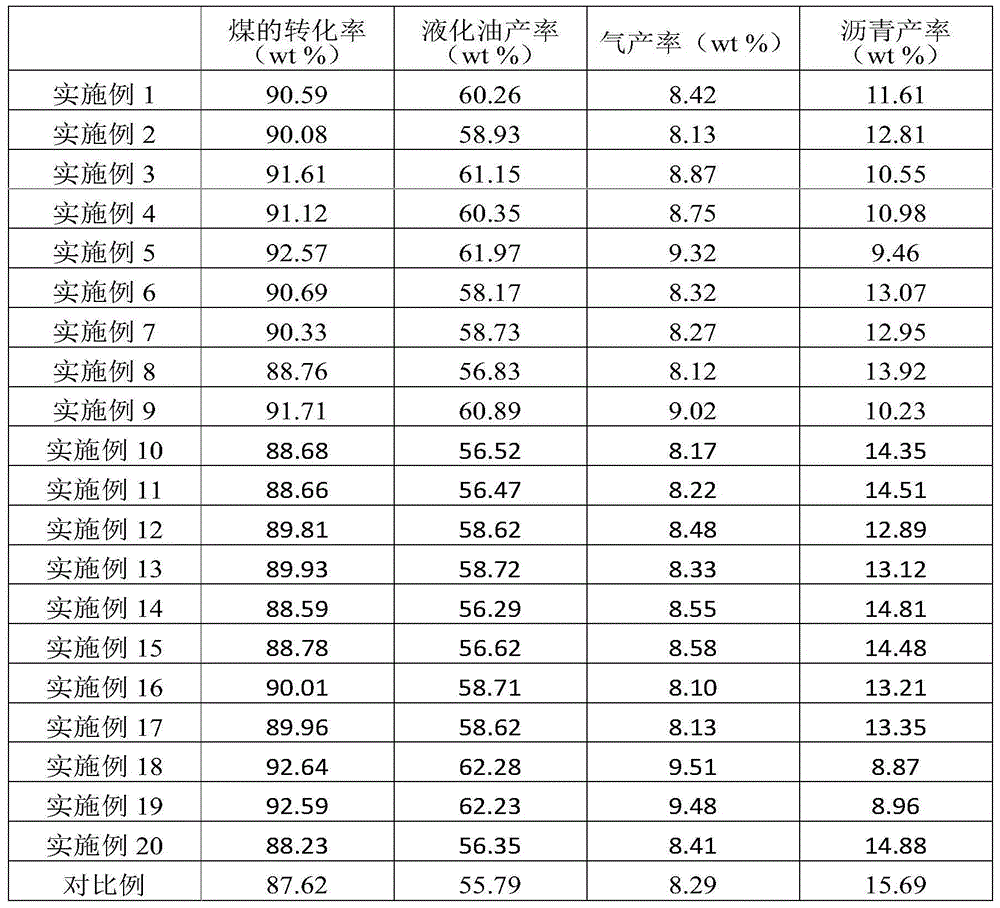

[0036] The preparation method provided by the present invention uses AlOOH, silicon dioxide and FeOOH as raw materials, and through slurry mixing and catalyst carrier introduction, an iron-based catalyst containing both structural additives AlOOH and silicon dioxide and active component FeOOH is obtained. The presence of AlOOH and silicon dioxide in the structural aid can reduce the particle size of the active ingredient FeOOH, making it ultra-fine and highly dispersed amorphous. At the same time, AlOOH can play the role of dispersing FeOOH particles, so that the generated FeOOH particles are not easy to agglomerate during the dehydration and drying process. Si atoms in silicon dioxide can enter the FeOOH crystal lattice and interact with Fe atoms to form a certain number of Fe-O-Si, thus playing the role of separating and dispersing FeOOH crystal grains. Furthermore, under the internal and external effects of AlOOH and silica, when the iron-based catalyst is under coal liquef...

Embodiment 1

[0051] Weigh 248.23g FeSO 4 ·7H 2 O and 34.72g Al(NO 3 ) 3 9H 2 O was added to 2000g deionized water, fully stirred and dissolved to obtain the first mixture; the concentrated ammonia water with a concentration of 27wt% was added to deionized water to form a dilute ammonia solution, and then 10.71g of SiO-containing 2 The silica sol with a concentration of 30 wt% and a pH value of 9 is added to the prepared ammonia solution, fully stirred and mixed uniformly to form a second mixture;

[0052] Using a peristaltic pump, the above-mentioned first mixture and the second mixture were added into a 10L reactor containing 1000g of water in parallel to carry out precipitation reaction. Wherein, the reactor is kept warm by circulating water in the jacket to control the reaction temperature to be 45° C., the feed time of the first mixture is 25 minutes, and the feed rate of ammonia water is controlled to maintain the reaction pH value at 7.0. After the first mixture was fed, compres...

Embodiment 2

[0055] Weigh 248.23g FeSO 4 ·7H 2 O and 104.17g Al(NO 3 ) 3 9H 2 O was added to 2000g deionized water, fully stirred and dissolved to obtain the first mixture; the concentrated ammonia water with a concentration of 27wt% was added to deionized water to form a dilute ammonia solution, and then 12.86g of SiO-containing 2 The silica sol with a concentration of 30 wt% and a pH value of 9 is added to the prepared ammonia solution, fully stirred and mixed uniformly to form a second mixture;

[0056] Using a peristaltic pump, the above-mentioned first mixture and the second mixture were added into a 10L reactor containing 1000g of water in parallel to carry out precipitation reaction. Wherein, the reactor is kept warm by circulating water in the jacket to control the reaction temperature to be 45°C, the feed time of the first mixture is 25 minutes, and the feed rate of ammonia water is controlled to maintain the reaction pH value as 7.0; the first After the mixture solution was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com