A method for enriching and recovering tellurium dioxide from tellurium-containing soda slag

A technology of tellurium dioxide and soda slag, which is applied in the field of separation chemistry, can solve problems such as low product purity, low yield, and complicated operations, and achieve the effects of increasing tellurium leaching rate, strong fine grinding force, and shortening leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

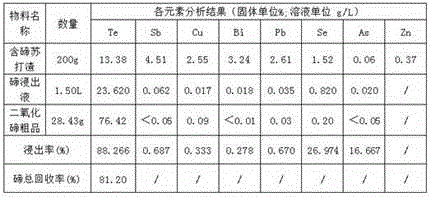

Embodiment 1

[0026] Raw material: tellurium-containing soda slag; elemental analysis shows that the raw material contains Te 13.38%, Sb 4.51%, Cu 2.55%, Bi 3.24%, Pb 2.61%, Se 1.52%, As 0.06%, Zn 0.37%.

[0027] Leaching agent: prepared by mixing 40 parts of sodium hydroxide, 40 parts of quicklime, 20 parts of sodium sulfide and 0.1 part of sodium polyacrylate.

[0028] In a 5L vertical spiral agitation mill, add 200g of tellurium-containing soda slag with a particle size of less than 5mm, 1000ml of water at 95°C, and 60g of the above-mentioned leaching agent in sequence, and turn on the vertical spiral agitation mill for fine grinding, stirring and leaching Work; pour out the reacted slurry after 30 minutes, vacuum filter and wash to obtain 1500ml of tellurium leaching solution; add sulfuric acid solution to the filtered tellurium leaching solution to neutralize the solution so that the pH value of the solution reaches 3-5, then filter and wash 1. Dry the precipitate to obtain 28.85 g of ...

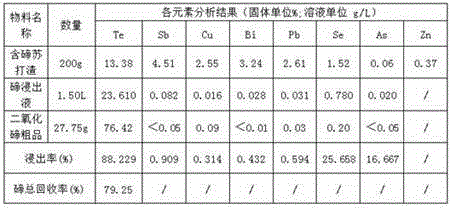

Embodiment 2

[0033] Raw material: tellurium-containing soda slag; elemental analysis shows that the raw material contains Te 13.38%, Sb 4.51%, Cu 2.55%, Bi 3.24%, Pb 2.61%, Se 1.52%, As 0.06%, Zn 0.37%.

[0034] Leaching agent: The leaching agent is prepared by mixing 45 parts of sodium hydroxide, 40 parts of quicklime, 15 parts of sodium sulfide and 0.5 part of sodium polyacrylate.

[0035] In a 5L vertical spiral agitation mill, add 200g of tellurium-containing soda slag with a particle size of less than 5mm, 1000ml of water at 95°C, and 40g of the above-mentioned leaching agent in sequence, and turn on the vertical spiral agitation mill for fine grinding, stirring and leaching Work; pour out the reacted slurry after 30 minutes, vacuum filter and wash to obtain 1500ml of tellurium leaching solution; add sulfuric acid solution to the filtered tellurium leaching solution to neutralize the solution so that the pH value of the solution reaches 3-5, then filter and wash 1. Dry the precipitate...

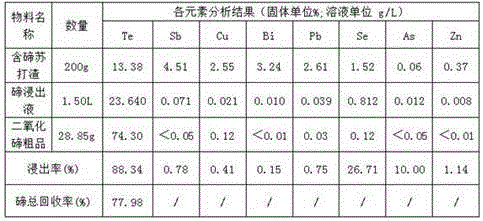

Embodiment 3

[0040] Raw material: tellurium-containing soda slag; elemental analysis shows that the raw material contains Te 13.38%, Sb 4.51%, Cu 2.55%, Bi 3.24%, Pb 2.61%, Se 1.52%, As 0.06%, Zn 0.37%.

[0041] Leaching agent: Take 50 parts of sodium hydroxide, 40 parts of quicklime, 10 parts of sodium sulfide, and 0.3 part of sodium polyacrylate, and mix them uniformly to prepare the leaching agent.

[0042]In a 5L vertical spiral agitation mill, add 200g of tellurium-containing soda slag with a particle size of less than 5mm, 1000ml of water at 95°C, and 30g of the above-mentioned leaching agent in sequence, and turn on the vertical spiral agitation mill for fine grinding, stirring and leaching Work; pour out the reacted slurry after 30 minutes, vacuum filter and wash to obtain 1500ml of tellurium leaching solution; add sulfuric acid solution to the filtered tellurium leaching solution to neutralize the solution so that the pH value of the solution reaches 3-5, then filter and wash 1. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com