Method for extracting boron by solvent extraction-ion exchange adsorption combination

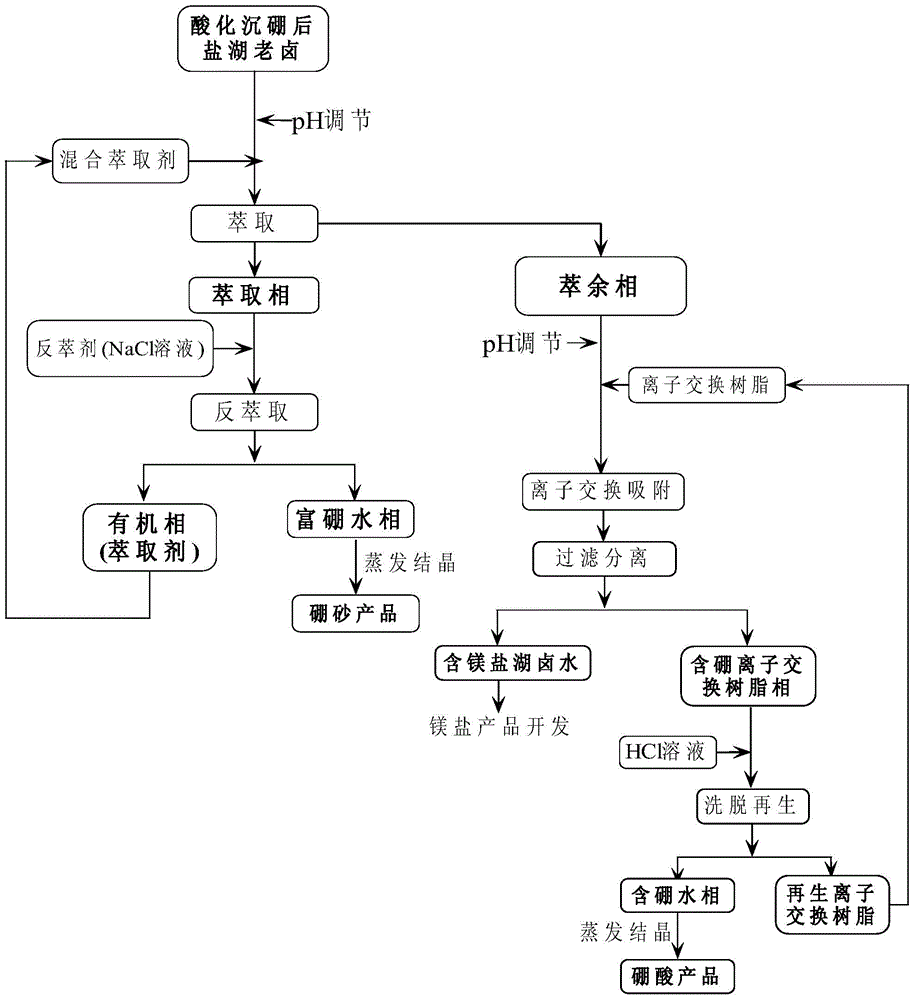

An ion-exchange adsorption and ion-exchange resin technology, which is applied in the field of extraction of boron by the combination of solvent extraction and ion-exchange adsorption, the development and comprehensive utilization of salt lake brine water resources, and can solve the problems that are not suitable for high-content boron-containing brine extraction, boron element It is difficult to extract and separate, and there are many extraction and stripping stages, so as to reduce the number of boron extraction stages, reduce energy consumption, and reduce dissolution loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (a) take the magnesium-containing salt lake old brine after salt lake acidification and boron precipitation as raw material liquid 100mL, boron content (in B 2 o 3 Meter) is 10.005g / L, and the pH value that pH meter records raw material solution is less than 1.0. The pH value of the old salt lake brine was adjusted to 1.0 with 0.5mol / L NaOH solution.

[0051] (b) Preparation of mixed extractant system: Take 50mL of aviation kerosene, add 34mL of n-decyl alcohol, 15mL of isooctyl alcohol, and 1mL of tributyl phosphate, stir and mix thoroughly, the total mass is 81.67g, and then add 2,2,4- Trimethyl-1,3-pentanediol is 2.80g, and the mass fraction of 2,2,4-trimethyl-1,3-pentanediol in the total extractant is 3.31%. After fully stirring and dissolving, a mixed extractant system.

[0052] (c) Use the mixed extractant system to extract the magnesium-containing salt lake old brine after acidification and boron precipitation, the volume ratio of the extraction agent (O) to t...

Embodiment 2

[0057] (a) take the magnesium-containing salt lake old brine after salt lake acidification and boron precipitation as raw material liquid 100mL, boron content (in B 2 o 3 ) is 10.005g / L, and the pH value of the old salt lake brine is adjusted to 5.0 with 5mol / L NaOH solution.

[0058] (b) Preparation of mixed extractant system: Take 50mL of aviation kerosene, add 18mL of n-decyl alcohol, 30mL of isooctyl alcohol, and 2mL of tributyl phosphate, stir and mix thoroughly, the total mass is 80.62g, and then add 2,2,4- Trimethyl-1,3-pentanediol 4.24g, then the mass fraction of 2,2,4-trimethyl-1,3-pentanediol in the total extractant is 5.0%, after fully stirring and dissolving, a mixed extractant system.

[0059] (c) Use the mixed extractant system to extract the magnesium-containing salt lake old brine after acidification and boron precipitation, the volume ratio of the extraction agent (O) to the salt lake old brine (W) is 1:1, the mixing time of the two is 20 minutes, and let it...

Embodiment 3

[0064] (a) take the magnesium-containing salt lake old brine after salt lake acidification and boron precipitation as raw material liquid 100mL, boron content (in B 2 o 3 Meter) is 10.005g / L, the pH value of raw material solution is adjusted to 3.0 with the NaOH solution of 2mol / L.

[0065] (b) Preparation of mixed extractant system: Take 50mL of aviation kerosene, add 30mL of n-decyl alcohol, 18mL of isooctyl alcohol, and 2mL of tributyl phosphate, stir and mix thoroughly, the total mass is 81.18g, and then add 2,2,4- Trimethyl-1,3-pentanediol is 3.38g, and the mass fraction of 2,2,4-trimethyl-1,3-pentanediol in the total extractant is 4.0%. After fully stirring and dissolving, a mixed extractant system.

[0066] (c) Use the mixed extractant system to extract the magnesium-containing salt lake old brine after acidification and boron precipitation, the volume ratio of the extraction agent (O) to the salt lake old brine (W) is 3:1, the mixing time of the two is 20 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com