Method for preparing sodium hydrogen carbonate for flue gas purification by using alkali wastes

A sodium bicarbonate and flue gas purification technology, applied in the field of flue gas purification, can solve the problems of staying in the crude product stage, increasing the industrial scale, and increasing the cost investment of the preparation process, achieving significant social benefits, solving environmental pollution, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

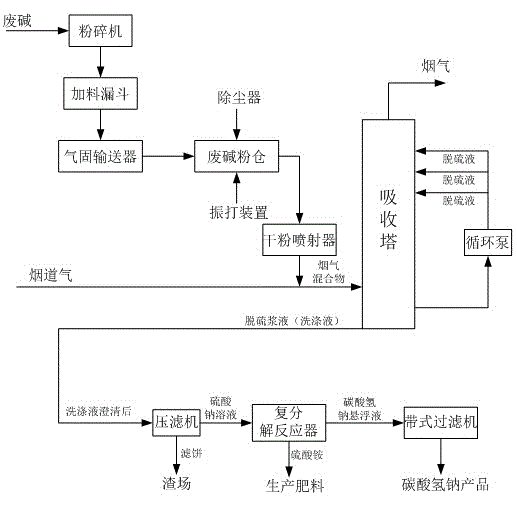

Image

Examples

Embodiment 1

[0072] The preparation method of the present embodiment comprises the steps:

[0073] A: Preparation of sodium sulfate solution: mix waste caustic soda with flue gas, purify pollutants in flue gas to obtain flue gas mixture, and then cycle wash the flue gas mixture to obtain Na 2 SO 4 Washing solution with a concentration of 24%;

[0074] B: Sodium bicarbonate unit: send the washing solution obtained in the above steps into the reactor, and react with ammonium bicarbonate to obtain a sodium bicarbonate suspension;

[0075] C: purification: the sodium bicarbonate suspension is purified to obtain the sodium bicarbonate product,

[0076] In the above steps, the spent caustic soda is a dry solid, and by weight percentage, the spent caustic soda comprises the following components:

[0077] Na 2 CO 3 : 72%;

[0078] Na 2 SO 4 : 20%;

[0079] Others: 8%,

[0080] Pollutants in flue gas include the following components:

[0081] SO 2 and SO 3 : Total 4500mg / Nm 3 ;

[0...

Embodiment 2

[0084] The preparation method of the present embodiment comprises the steps:

[0085] A: Preparation of sodium sulfate solution: mix waste caustic soda with flue gas, purify pollutants in flue gas to obtain flue gas mixture, and then cycle wash the flue gas mixture to obtain Na 2 SO 4 Washing solution with a concentration of 28%;

[0086] B: Sodium bicarbonate unit: send the washing solution obtained in the above steps into the reactor, and react with ammonium bicarbonate to obtain a sodium bicarbonate suspension;

[0087] C: purification: the sodium bicarbonate suspension is purified to obtain the sodium bicarbonate product,

[0088] In the above steps, the spent caustic soda is a dry solid, such as: sodium bicarbonate spent caustic soda, by weight percentage, the spent caustic soda comprises the following components:

[0089] Na 2 CO 3 : 80%;

[0090] Na 2 SO 4 : 15%;

[0091] Others: 5%,

[0092] Pollutants in flue gas include the following components:

[0093] S...

Embodiment 3

[0096] The preparation method of the present embodiment comprises the steps:

[0097] A: Preparation of sodium sulfate solution: mix waste caustic soda with flue gas, purify pollutants in flue gas to obtain flue gas mixture, and then cycle wash the flue gas mixture to obtain Na 2 SO 4 Washing solution with a concentration of 28%;

[0098] B: Sodium bicarbonate unit: send the washing solution obtained in the above steps into the reactor, and react with ammonium bicarbonate to obtain a sodium bicarbonate suspension;

[0099] C: purification: the sodium bicarbonate suspension is purified to obtain the sodium bicarbonate product,

[0100] In the above steps, the spent caustic soda is dry solid, such as: caprolactam incineration spent caustic soda, by weight percentage, spent caustic soda comprises the following components:

[0101] Na 2 CO 3 : 85%;

[0102] Na 2 SO 4 : 17%;

[0103] Others: 3%,

[0104] Pollutants in flue gas include the following components:

[0105] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com