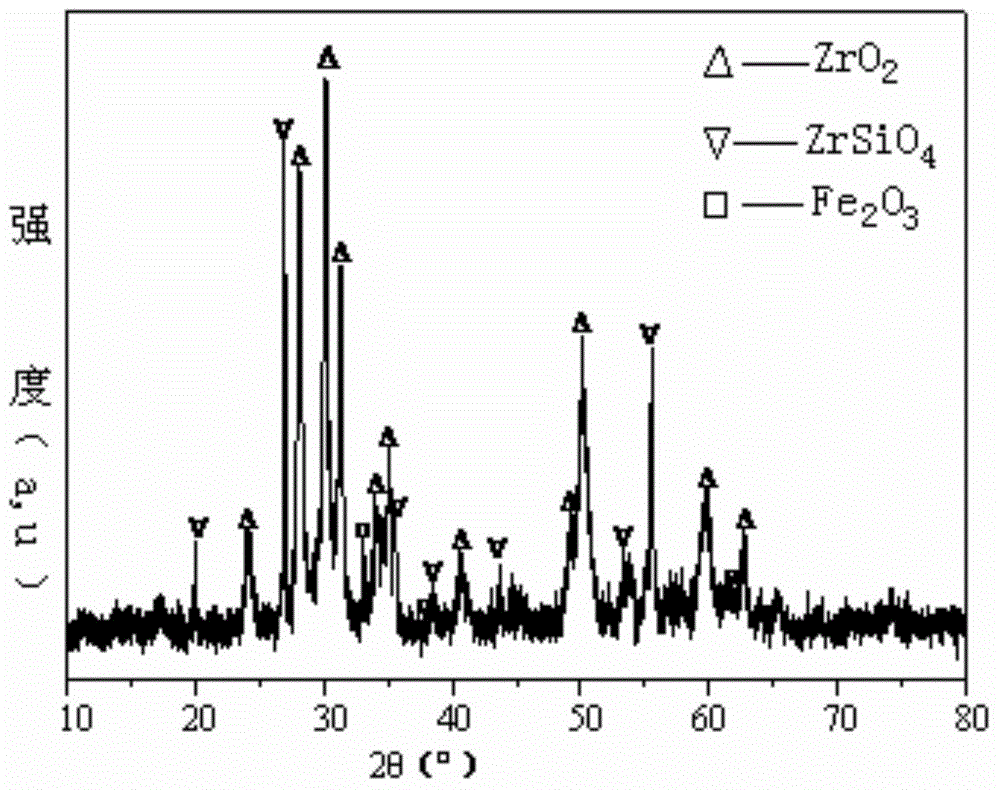

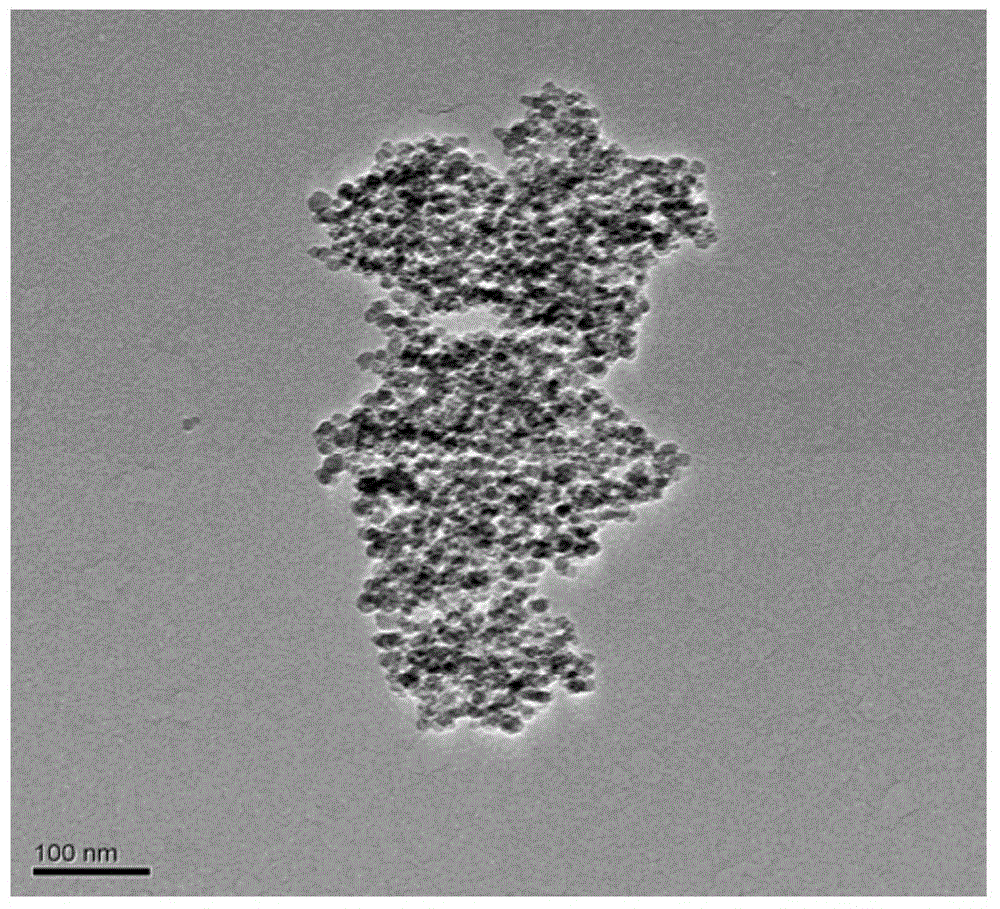

Organic network preparation method of ferrozirconium red zirconia nano-composite ceramic powder

An organic network and nano-composite technology, applied in zirconia and other directions, can solve the problems of uneven mixing of solid-phase raw materials, excessive hydrolysis speed, and inability to form gels, and achieve accurate product composition control, simple production equipment, and reduced sintering. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of organic network precursor solution: mix polyvinyl alcohol and water uniformly at a mass ratio of 3:100, heat and stir at 80°C for 3 hours, then let stand and cool to room temperature to obtain a polyvinyl alcohol aqueous solution, which is Organic network precursor solution;

[0026] 2) Zr 4+ And the preparation of colored ion / organic network gel: take 57g of the organic network precursor solution prepared above, add 30g of zirconium oxychloride and 0.18g of ferric nitrate nonahydrate in sequence and stir until completely dissolved, then add 0.68g The silica sol was stirred well, then 0.95g of glutaraldehyde was added and stirred rapidly to form Zr 4+ and colored ionic / organic network gels;

[0027] 3) Zr 4+ and coloring ion / organic network gel post-treatment: the above Zr 4+ After standing for 5 hours with the colored ion / organic network gel, place it in 25% ammonia water and soak it for 12 hours, then wash it with deionized water until neutral, t...

Embodiment 2

[0032] 1) Preparation of organic network precursor solution: mix polyvinyl alcohol and water uniformly at a mass ratio of 5:100, heat and stir at 85°C for 2.5 hours, then let stand and cool to room temperature to obtain polyvinyl alcohol aqueous solution, which is Organic network precursor solution;

[0033] 2) Zr 4+ And the preparation of colored ion / organic network gel: take 60g of the organic network precursor solution prepared above, add 30g of zirconium oxychloride and 0.25g of ferric nitrate nonahydrate in sequence and stir until completely dissolved, then add 0.94g The silica sol was stirred well, then 1g of glutaraldehyde was added and stirred rapidly to form Zr 4+ and colored ionic / organic network gels;

[0034] 3) Zr 4+ and coloring ion / organic network gel post-treatment: the above Zr 4+ After standing for 4 hours with the colored ion / organic network gel, place it in 26% ammonia water and soak it for 11 hours, then wash it with deionized water until it is neutral...

Embodiment 3

[0037] 1) Preparation of organic network precursor solution: mix polyvinyl alcohol and water uniformly at a mass ratio of 8:100, heat and stir at 90°C for 2 hours, then let stand and cool to room temperature to obtain an aqueous solution of polyvinyl alcohol, which is Organic network precursor solution;

[0038] 2) Zr 4+ And the preparation of colored ion / organic network gel: take 58g of the organic network precursor solution prepared above, add 30g of zirconium oxychloride and 0.33g of ferric nitrate nonahydrate in sequence and stir until completely dissolved, then add 0.79g The silica sol was stirred well, then 1.05 g of glutaraldehyde was added and stirred rapidly to form Zr 4+ and colored ionic / organic network gels;

[0039] 3) Zr 4+ and coloring ion / organic network gel post-treatment: the above Zr 4+ After standing for 5 hours with the colored ion / organic network gel, soak in ammonia water with a mass percentage concentration of 28% for 10 hours, then wash with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com