Lead-free porcelain imitation glass wine bottle and manufacture process thereof

A glass and wine bottle technology, used in glass manufacturing equipment, manufacturing tools, glass pressing, etc., can solve the problems of inability to penetrate the bottle body, and achieve the effect of simple production process, uniform texture, and easy transportation and sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Take 50 parts of quartz sand, 12 parts of soda ash, 11 parts of calcite, 5 parts of superfine talcum powder, 3 parts of magnesium chloride, 2 parts of sodium nitrate and 5 parts of tin oxide by weight and mix well.

[0022] (2) Enter the furnace through the conveyor belt, and heat the mixture to 1150°C for 12 hours;

[0023] (3) Add 2 parts of benzoic acid and 2 parts of dioxolane to the original mixture, make the temperature of the material reach 1300°C, and last for 35 minutes to remove air bubbles;

[0024] (4) Molded by a molding machine, the molding temperature is 800°C, the pressure is 4.5Mpa, and the time is 10 minutes;

[0025] (5) Send the formed lead-free imitation porcelain glass wine bottle into the annealing furnace and anneal for 1.5 hours.

[0026] (6) Grinding and polishing with a grinder to obtain a finished product.

Embodiment 2

[0028] (1) Take 47 parts of quartz sand, 11 parts of soda ash, 10 parts of calcite, 6 parts of superfine talcum powder, 2 parts of magnesium chloride, 3 parts of sodium sulfate, 5 parts of aluminum oxide, 2 parts of tin oxide, and 2 parts of coupling agent by weight Mix well.

[0029] (2) Enter the furnace through the conveyor belt, and heat the mixture to 1200°C for 10 hours;

[0030] (3) Add 1 part of silicon phosphate and 1 part of vinyl triperoxy-tert-butylsilane to the original mixture, make the temperature of the material reach 1300°C, and last for 45 minutes to remove air bubbles;

[0031] (4) Molded by a molding machine, the molding temperature is 700°C, the pressure is 4Mpa, and the time is 8-10 minutes.

[0032] (5) Send the formed lead-free imitation porcelain glass wine bottle into the annealing furnace and anneal for 1 hour.

[0033] (6) Grinding and polishing with a grinder to obtain a finished product.

Embodiment 3

[0035] (1) Take 35 parts of quartz sand, 9 parts of soda ash, 8 parts of calcite, 5 parts of superfine talcum powder, 2 parts of magnesium chloride, 3 parts of sodium sulfate and 4 parts of tin oxide in parts by weight and mix well.

[0036] (2) Enter the furnace through the conveyor belt, and heat the mixture to 1000°C for 10 hours;

[0037] (3) Add 0.5 parts of silicon phosphate and 0.5 parts of dioxolane to the original mixture, so that the temperature of the material reaches 1300 ° C, and last for 20 minutes to remove air bubbles;

[0038] (4) Molded by a molding machine, the molding temperature is 600°C, the pressure is 3Mpa, and the time is 8-10 minutes.

[0039] (5) Send the formed lead-free imitation porcelain glass wine bottle into the annealing furnace and anneal for 0.5 hours.

[0040] (6) Grinding and polishing with a grinder to obtain a finished product.

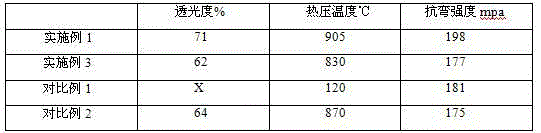

[0041] The parameters of Example 1, Example 3, Patent 201210593455X (Comparative Example 1), and Patent 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com