Self-cleaning real stone paint and preparation method thereof

A real stone paint and self-cleaning technology, which is applied in the field of self-cleaning real stone paint and its preparation, can solve the problems of lack of preparation methods for self-cleaning real stone paint, troubles in the social environment of buildings, and rare building surfaces, etc., to achieve prolonged cleaning time, good freeze-thaw resistance, and reduced contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

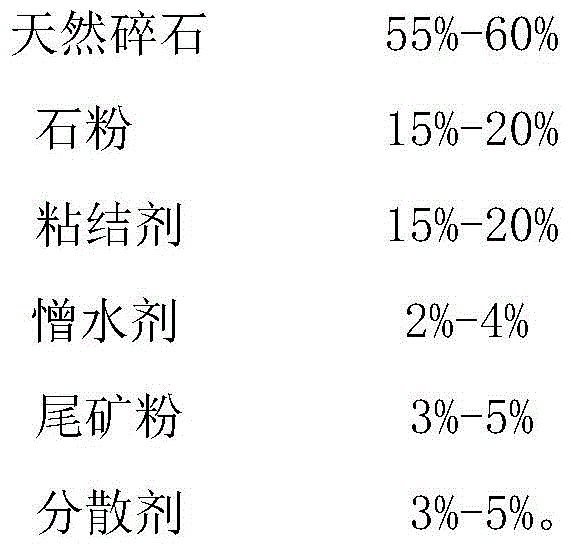

[0024] The invention provides a kind of self-cleaning real stone paint, which is composed of the following components by mass percentage:

[0025]

[0026] The binder is inorganic gelling synthetic resin and synthetic resin emulsion. The tailings powder contains silicon, and the content of the silicon accounts for more than 65% of the total amount of the tailings powder.

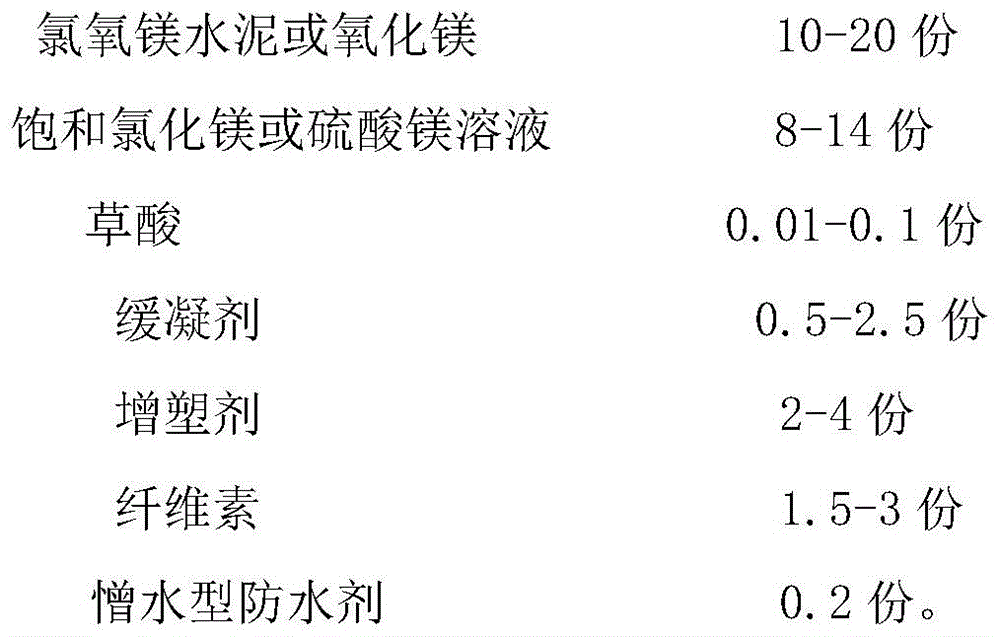

[0027] The binder is made of the following components in parts by weight:

[0028]

[0029] A kind of method for preparing described self-cleaning real stone paint of the present invention, comprises the steps:

[0030] (1) Pulverize the natural crushed stone to a diameter of 0.2cm; in order to maintain the effect of marble, no pigments or dyes can be added;

[0031] (2) take by weighing the natural gravel, stone powder, binder, water repellent, tailings powder and dispersant of the above-mentioned proportions for subsequent use; mix the stone powder and tailings powder into the natural gravel partic...

Embodiment 2

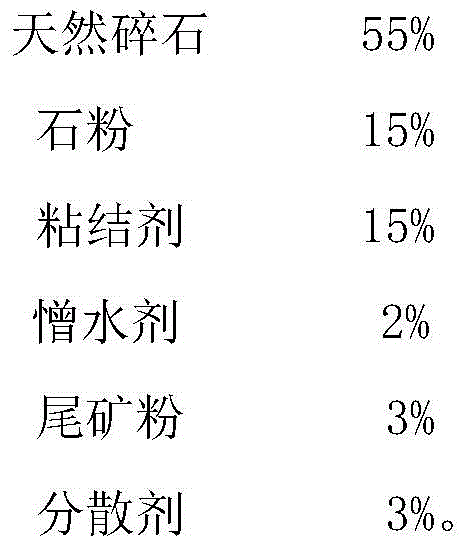

[0039] The difference between embodiment 2 and embodiment 1 is: the present invention provides a kind of self-cleaning real stone paint, which is made up of the following components by mass percentage:

[0040]

[0041] The binder is an inorganic gelling synthetic resin.

[0042] The tailings powder contains silicon, and the content of the silicon accounts for more than 65% of the total amount of the tailings powder.

[0043] The binder is made of the following components in parts by weight:

[0044]

[0045] A kind of method for preparing described self-cleaning real stone paint of the present invention, comprises the steps:

[0046] In step (1), the natural crushed stone is pulverized to a diameter of 0.6 cm;

[0047] In step (2), take by weighing the natural crushed stone, stone powder, binder, water repellent, tailings powder and dispersant of the above-mentioned proportions for subsequent use; The stone powder and tailings powder are mixed into the natural crushed...

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is: the present invention provides a kind of self-cleaning real stone paint, which is made up of the following components by mass percentage:

[0051]

[0052] The binder is a synthetic resin emulsion.

[0053] The tailings powder contains silicon, and the content of the silicon accounts for more than 65% of the total amount of the tailings powder.

[0054] The binder is made of the following components in parts by weight:

[0055]

[0056] A kind of method for preparing described self-cleaning real stone paint of the present invention, comprises the steps:

[0057]In step (1), the natural gravel is crushed to a diameter of 0.8cm; in step (2), the natural gravel, stone powder, binder, water repellent, tailings powder and dispersion Mix the stone powder and tailings powder into the natural gravel particles, stir evenly, then add water-repellent agent to stir, stir for 5 minutes, add binder and stir to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com