Method for separating acetophenone and alpha-phenethyl alcohol from mixture of acetophenone and alpha-phenethyl alcohol

A technology of acetophenone and phenethyl alcohol, applied in the separation field of chemical industry and perfume, can solve the problems of high cost, difficult to realize industrialization, low separation purity and the like, and achieve the effects of preventing oxidation, low cost and short separation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

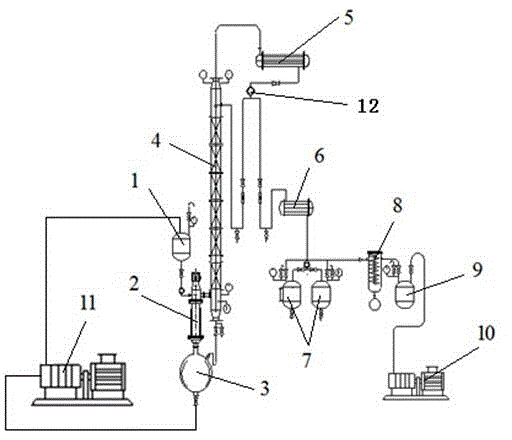

Image

Examples

Embodiment 1

[0019] The method for separating acetophenone, α-phenylethyl alcohol binary components from acetophenone and α-phenylethyl alcohol mixture of the present invention comprises the steps:

[0020] Put 400.0 g of a mixture of 50% acetophenone and 50% α-phenylethanol into the material tank 1, control the temperature of the rectification column at 80 °C, the evaporation temperature at 105 °C, and total reflux for 30 min, with a reflux ratio of 3 and The vacuum degree was 1200 Pa, and the components of this section were collected to obtain 152.0 g of acetophenone with a purity of 85.2% and 170.7 g of α-phenylethanol with a purity of 75.6%. Take 152.0 g of a mixture with acetophenone content of 85.2% and α-phenylethanol content of 14.8%, control the rectification column temperature at 72 °C, evaporation temperature at 91 °C, total reflux for 32 min, reflux ratio of 2 and vacuum degree of 1400 Pa, and collect 121.1 g of acetophenone with a purity of 99.6% was obtained for this segment ...

Embodiment 2

[0022] The method for separating acetophenone, α-phenylethyl alcohol from acetophenone and α-phenylethyl alcohol mixture of the present invention comprises the steps:

[0023] Put 400.0 g of the content mixture of acetophenone and α-phenylethanol in equal mass into material tank 1, control the rectification column temperature at 85 °C, evaporation temperature at 112 °C, total reflux for 40 min, reflux ratio of 3 and vacuum degree of 1200 Pa, The components of this section were collected to obtain 156.4 g of acetophenone with a purity of 88.4% and 174.0 g of α-phenylethanol with a purity of 77.1%. Take 156.4 g of a mixture with 88.4% acetophenone content and 11.6% α-phenylethanol content, control the rectification column temperature at 75 °C, evaporation temperature at 95 °C, total reflux for 35 min, reflux ratio of 2.4 and vacuum degree of 1500 Pa, and collect 126.3g of acetophenone with a purity of 99.4% was obtained for this segment of components; 174.0 g of a mixture with a...

Embodiment 3

[0025] The method for separating acetophenone, α-phenylethyl alcohol from acetophenone and α-phenylethyl alcohol mixture of the present invention comprises the steps:

[0026] Put 400.0 g of a mixture of equal mass of acetophenone and α-phenylethanol into material tank 1, control the rectification column temperature at 88°C, evaporation temperature at 110°C, total reflux for 35 min, reflux ratio of 4 and vacuum degree of 1400 Pa, The components of this section were collected to obtain 150.2 g of light components with a purity of 85.0%-acetophenone and 169.0 g of heavy components with a purity of 75.2%. Take 150.2 g of a mixture with 85.0% acetophenone content and 15.0% α-phenylethanol content, control the rectification column temperature at 80°C, evaporation temperature at 100°C, total reflux for 40 min, reflux ratio 3 and vacuum degree 1400 Pa, collect 128.2 g of acetophenone with a purity of 99.5% is obtained for this segment of components; 169.0 g of a mixture with a conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com