Method for preparing core-shell type carbon nanotube conductive fillers by virtue of controllable coating technology

A carbon nanotube and conductive filler technology, which is applied in the field of composite material preparation, can solve problems such as poor compatibility, uneven coating, and difficult production, and achieve the effects of improved dispersion, uniform coating, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

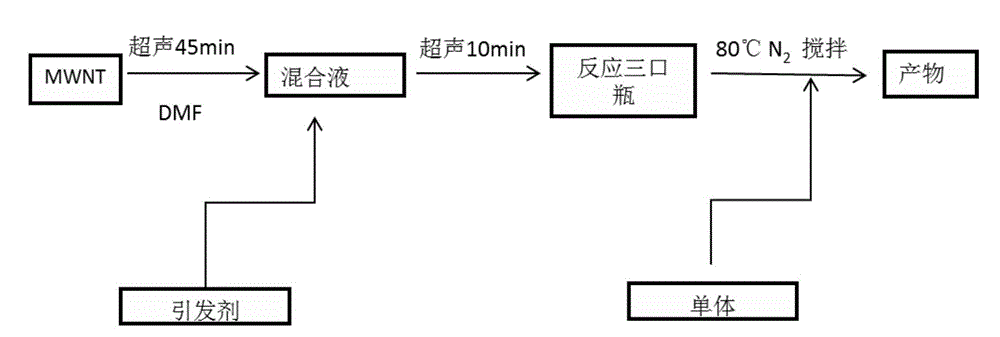

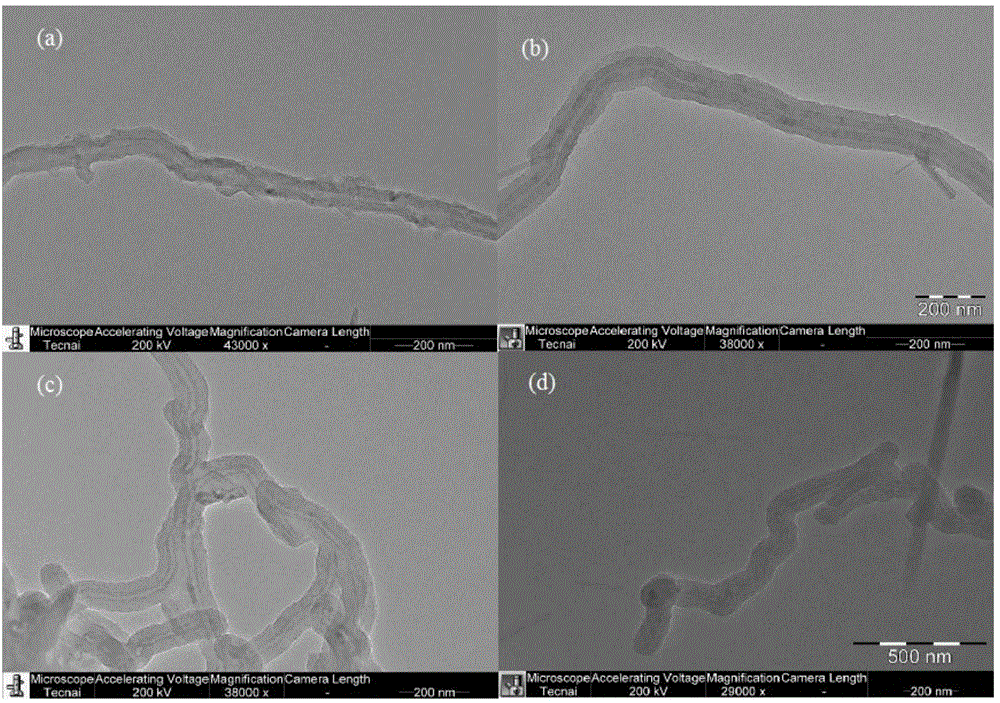

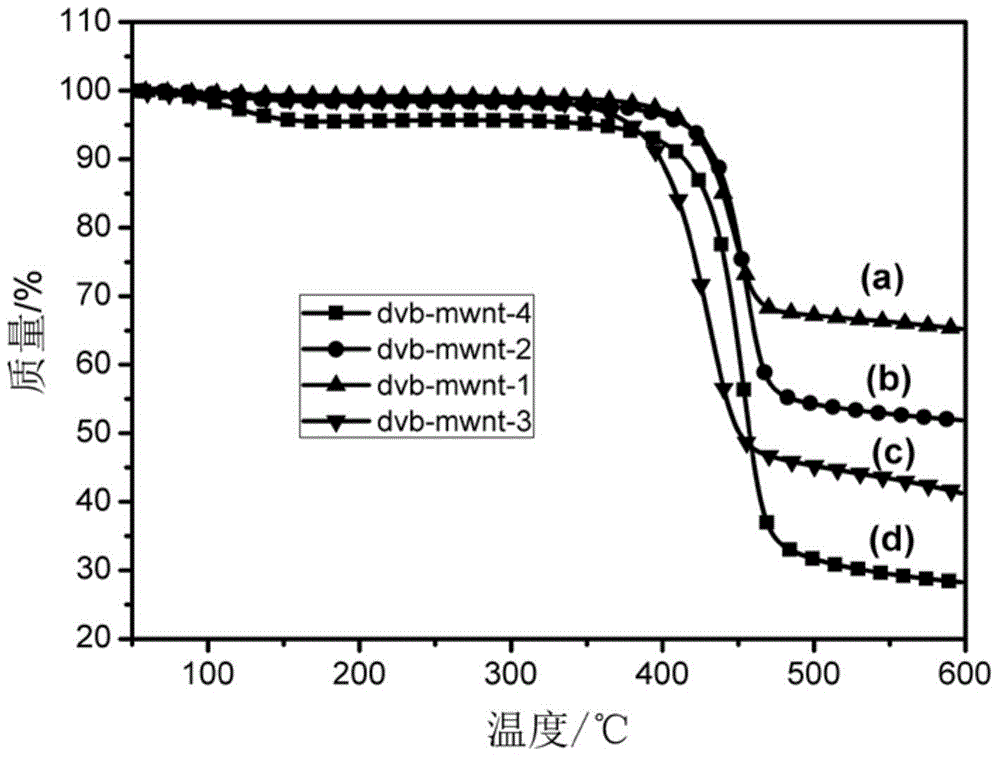

[0033] Weigh 150 mg of carbon nanotubes, place them in a three-necked flask, add 150 ml of N, N dimethylformamide (DMF) as a solvent, ultrasonically disperse for 45 min, add 25 mg of initiator azobisisobutyronitrile and continue ultrasonication for 10 min. Measure 0.15g of divinylbenzene (DVB) monomer and add it into the dropping device after dilution. The three-necked flask was moved into an oil bath, and stirred at room temperature for 1 h under the protection of nitrogen. The temperature was raised to 80°C, and the divinylbenzene (DVB) monomer in the dropping device was gradually added dropwise to carry out the polymerization reaction. After 12h, the heating was stopped to end the reaction. The product was obtained by suction filtration, washed with water and methanol respectively for 30 min, and finally the target product was obtained by suction filtration. figure 2 (a) is the core-shell composite of divinylbenzene-coated carbon nanotubes prepared in this example (the s...

Embodiment 2

[0035] Weigh 150 mg of carbon nanotubes, place them in a three-necked flask, add 150 ml of N,N dimethylformamide (DMF) as a solvent, and disperse them ultrasonically for 45 minutes. Add 25 mg of initiator azobisisobutyronitrile and continue sonication for 10 min. Measure 0.45g of divinylbenzene (DVB) monomer and add it into the dropping device after dilution. The three-necked flask was moved into an oil bath, and stirred at room temperature for 1 h under the protection of nitrogen. The temperature was raised to 80°C, and the monomer was gradually added dropwise to carry out the polymerization reaction. After 12h, the heating was stopped to end the reaction. The product was obtained by suction filtration, washed with water and methanol respectively for 30 min, and finally the target product was obtained by suction filtration. figure 2 (b) is a transmission electron micrograph of the core-shell composite of divinylbenzene-coated carbon nanotubes prepared in this example. It...

Embodiment 3

[0037]Weigh 150 mg of carbon nanotubes, place them in a three-necked flask, add 150 ml of N, N dimethylformamide (DMF) as a solvent, ultrasonically disperse for 45 min, add 25 mg of initiator azobisisobutyronitrile and continue ultrasonication for 10 min. Measure 0.75g of divinylbenzene (DVB) monomer, add it into the dripping device after dilution. The three-necked flask was moved into an oil bath, and stirred at room temperature for 1 h under the protection of nitrogen. The temperature was raised to 80°C, and the monomer was gradually added dropwise to carry out the polymerization reaction. After 12h, the heating was stopped to end the reaction. The product was obtained by suction filtration, washed with water and methanol respectively for 30 min, and finally the target product was obtained by suction filtration. figure 2 (c) is a transmission electron micrograph of the core-shell composite of divinylbenzene-coated carbon nanotubes prepared in this example. It can be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com