Polyurethane package material and preparation method thereof

A packaging material and polyurethane technology, applied in the field of structural materials and their preparation, packaging materials, and composite materials, can solve problems such as unfavorable environmental protection and soil and water conservation, damage to instruments and equipment, and poor anti-extrusion effect, and achieves the Conducive to soil and water conservation, low production cost and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of polyurethane packaging material and preparation method thereof, its preparation process is:

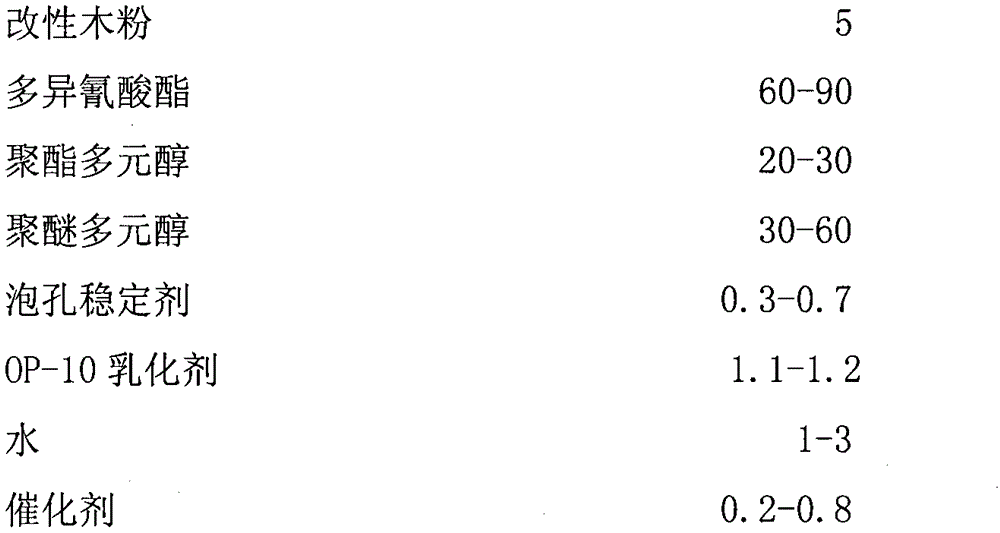

[0022]

[0023]

[0024] (1), be 2: 100 by weight ratio of glucanase and wood flour, take dextranase and wood flour; Mix glucanase and water by weight ratio 1: 25, wherein water is solvent, Prepare a dextranase solution;

[0025] (2) Spray the dextranase solution on the surface of the wood flour by spraying, and turn the wood flour while spraying to prepare the dextranase-modified wood flour, and place the dextranase-modified wood flour in an environment of 105°C Cool to room temperature after drying in medium to obtain modified wood flour;

[0026] (3), take each raw material by formula quantity;

[0027] (4), polyester polyol, polyether polyol, cell stabilizer, OP-10 emulsifier, water, and catalyst are placed in a mechanical stirring tank and stirred for 15 minutes to prepare a white material combination;

[0028] (5), the modified wood flour ...

Embodiment 2

[0030] Embodiment 2: a kind of polyurethane packaging material and preparation method thereof, its preparation process is:

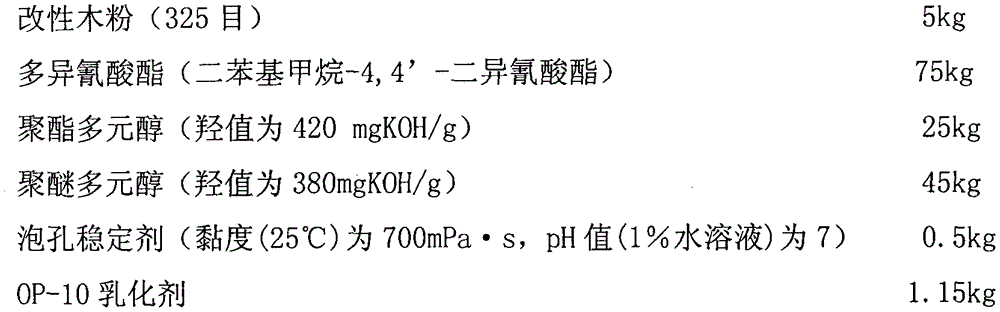

[0031]

[0032] (1), be 1: 100 by weight ratio of dextranase and wood powder, take by weighing glucanase and wood flour; Mix 1: 20 by weight of glucanase and water, wherein water is solvent, Prepare a dextranase solution;

[0033] (2) Spray the dextranase solution on the surface of the wood flour by spraying, and turn the wood flour while spraying to prepare the dextranase-modified wood flour, and place the dextranase-modified wood flour in an environment of 105°C Cool to room temperature after drying in medium to obtain modified wood flour;

[0034] (3), take each raw material by formula quantity;

[0035] (4) Put polyester polyol, polyether polyol, cell stabilizer, OP-10 emulsifier, water, and catalyst in a mechanical stirring tank and stir for 10 minutes to prepare a white material combination;

[0036] (5), the modified wood flour and polyisocy...

Embodiment 3

[0038] Embodiment 3: a kind of polyurethane packaging material and preparation method thereof, its preparation process is:

[0039]

[0040]

[0041] (1), be 3: 100 by weight ratio of glucanase and wood flour, take dextranase and wood flour; Mix glucanase and water by weight ratio 1: 30, wherein water is solvent, Prepare a dextranase solution;

[0042] (2) Spray the dextranase solution on the surface of the wood flour by spraying, and turn the wood flour while spraying to prepare the dextranase-modified wood flour, and place the dextranase-modified wood flour in an environment of 105°C Cool to room temperature after drying in medium to obtain modified wood powder;

[0043] (3), take each raw material by formula quantity;

[0044] (4), polyester polyol, polyether polyol, cell stabilizer, OP-10 emulsifier, water, catalyst were placed in a mechanical stirring tank and stirred for 20 minutes to prepare a white material combination;

[0045] (5), the modified wood flour an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com