Waterborne blocked polyisocyanate cross-linking agent with polyethyleneimine skeleton and preparation method of waterborne blocked polyisocyanate cross-linking agent

A technology of polyethyleneimine and polyisocyanate, which is applied in the field of water-based blocked polyisocyanate crosslinking agent and its preparation, can solve the problems of difficult control of the copolymerization process, great differences in product structure and residual active group content, etc., and achieve production The process is easy to control, the repeatability is strong, and the molecular structure is highly controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

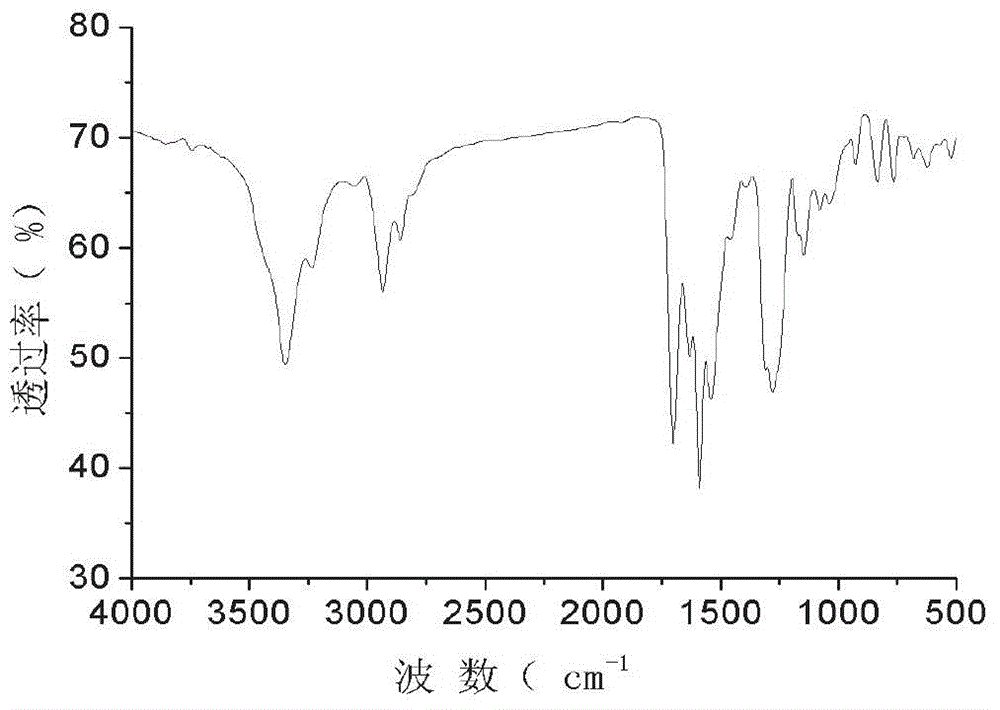

[0029] Example 1, under nitrogen protection and mechanical stirring, 10 grams of hexamethylene diisocyanate, 0.13 grams of dibutyltin dilaurate and 10 grams of cyclohexanone were added to a four-necked flask, and the temperature was slowly raised to 75 ° C. Add 5.89 grams of 3,5-dimethylpyrazole in batches to a four-necked flask, the addition time is 0.5 hours, and react for 3 hours; then add 10 grams of cyclohexanone and 11.67 grams of polyethyleneimine (molecular weight 1000) Into the reaction system, the feeding time is 30 minutes, and the reaction is 1.5 hours; finally, the reaction system is cooled to room temperature, and 16.22 grams of acetic acid are added in batches, the feeding time is 10 minutes, and the reaction is continued for 1 hour to obtain a water-based closed type polyethylenimine skeleton. Polyisocyanate crosslinker. figure 1 It is the infrared spectrum of the water-based blocked polyisocyanate crosslinking agent of the obtained polyethylenimine skeleton, F...

Embodiment 2

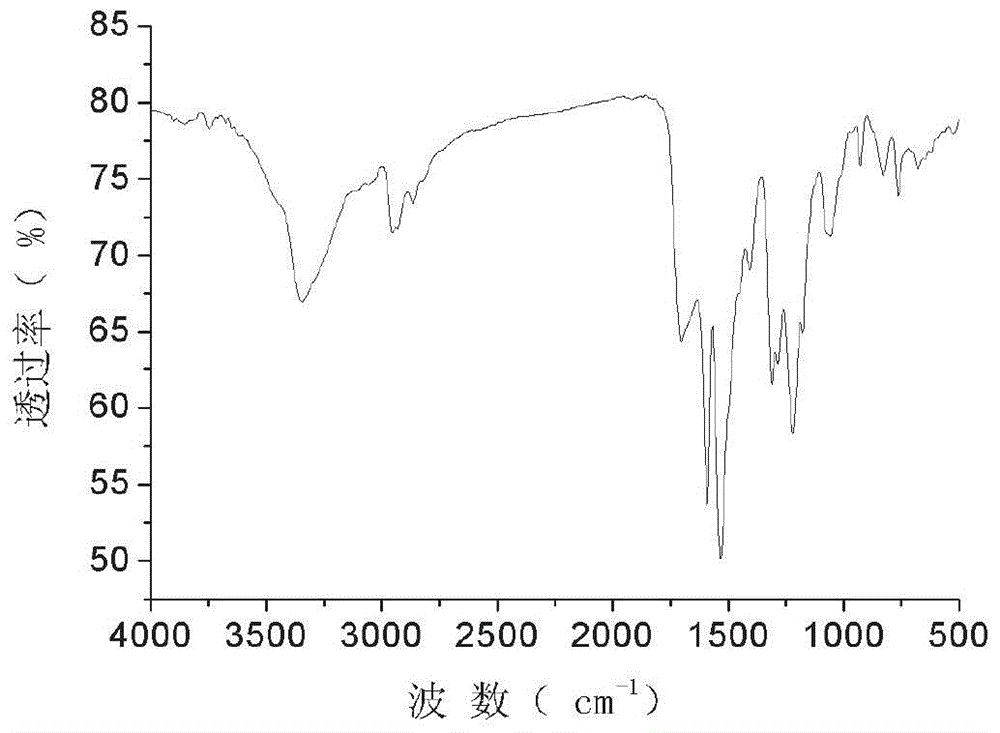

[0030] Example 2, under nitrogen protection and mechanical stirring, 10 grams of toluene diisocyanate, 0.18 grams of dibutyltin dilaurate and 15 grams of butanone were added to a four-necked flask, and the temperature was slowly raised to 60 ° C. 3.52 grams of Add imidazole into the four-necked flask in batches, the addition time is 0.5 hours, and react for 2 hours; then add 20 grams of butanone and 19.71 grams of polyethyleneimine (molecular weight 2000) to the reaction system, the addition time is 45 minutes, and react for 1 hour Finally, the reaction system was cooled to room temperature, and 27.5 grams of acetic acid was added in batches for 12 minutes, and the reaction was continued for 1 hour to obtain a water-based blocked polyisocyanate crosslinking agent with a polyethyleneimine skeleton. Such as figure 2 Shown is the infrared spectrum of the water-based blocked polyisocyanate crosslinking agent of the obtained polyethyleneimine skeleton, FT-IR (KBr, cm -1 ): 3346(N...

Embodiment 3

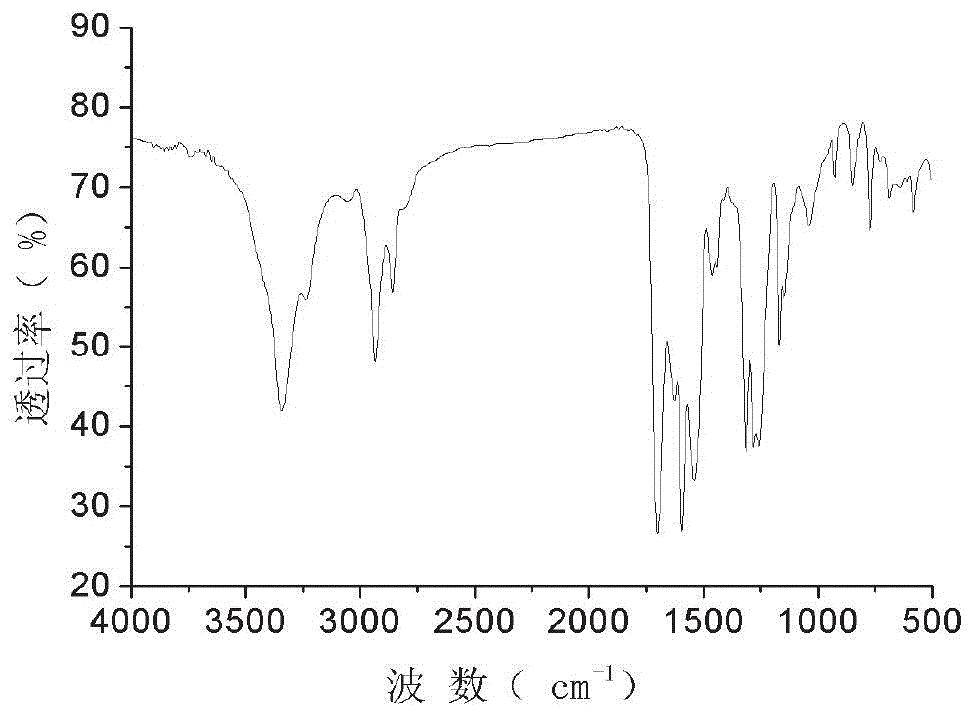

[0031] Example 3, under nitrogen protection and mechanical stirring, 10 grams of isophorone diisocyanate, 0.28 grams of stannous octoate and 12 grams of 1,4-dioxane were added to a four-necked flask, and the temperature was slowly raised to At 70°C, add 3.84 grams of methyl ethyl ketone oxime to a four-necked flask in batches for 0.5 hours, and react for 2.5 hours; then add 30 grams of 1,4-dioxane and 33.56 grams of polyethyleneimine (molecular weight 4000) Added to the reaction system, the feeding time is 1 hour, and the reaction is 2 hours; finally, the reaction system is cooled to room temperature, and 46.83 grams of acetic acid is added in batches, the feeding time is 15 minutes, and the reaction is continued for 1 hour to obtain the aqueous sealing of polyethyleneimine skeleton. Type polyisocyanate crosslinking agent. Such as image 3 Shown is the infrared spectrum of the water-based blocked polyisocyanate crosslinking agent of the obtained polyethyleneimine skeleton, FT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com