Intumescent phosphorus-containing grafted polymer flame retardant as well as preparation and application thereof

A polymer flame retardant, intumescent technology, used in fiber types, textiles and paper making, fiber processing, etc. Excellent performance, smooth and smooth coating, excellent decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

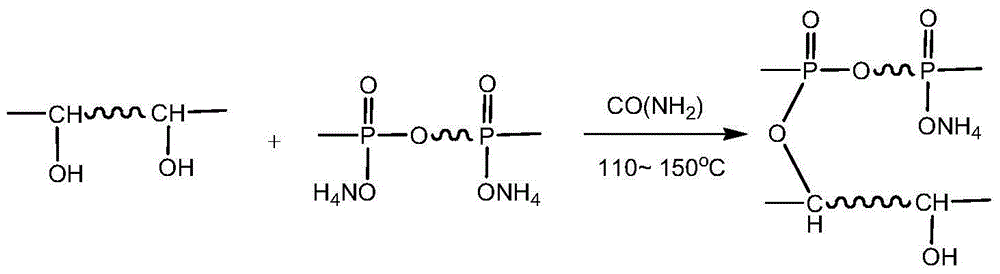

Method used

Image

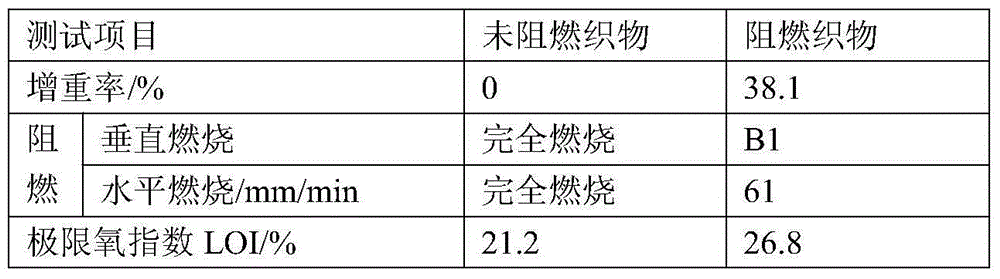

Examples

Embodiment 1

[0033] Synthesis of PUPVA:

[0034] Weigh 50 parts of polyvinyl alcohol 1799 and wet it with a small amount of water, add it to 200 parts of water, stir and dissolve it into a colorless transparent liquid at 50-90°C; add 25 parts of ammonium polyphosphate, and then add 10 parts of urea phosphate to mix Fully stir in the liquid; disperse into a uniform transparent liquid, transfer to a glass plate and dry at 50-100°C, then bake at 110-150°C for 10-30 minutes to obtain foaming white modified polyvinyl urea salt PUPVA, yield 92%. The infrared spectrum data of modified polyvinyl urea salt PUPVA are as follows: 3510-3050, 2915, 2898, 1689, 1472, 1321, 1133, 1089, 982. PUPVA's 1 H-NMR data: the displacement value is 1.4~1.5ppm (m, J=42.2Hz, 2H, CH 2 ) and 3.7~3.8ppm (d, J=24.5Hz, 1H, CH) peaks are respectively -CH on the main chain 2 - and -CH- peaks, while the chemical shift is between 4.6 and 6.3ppm (d, br, 2H, -NH 2 , -OH) are OH and -NH in PUPVA 2 , the weak peak at 7.2ppm...

Embodiment 2

[0043] Synthesis of PMAPVA:

[0044] Weigh 30g of polyvinyl alcohol 2099 and wet it with a small amount of water, add it to 200 parts of water, stir and dissolve it into a colorless transparent liquid at 80°C; add 15 parts of melamine phosphate and 10 parts of ammonium polyphosphate, and then add 5 parts of Add the dicyandiamide catalyst into the mixed liquid and stir well; disperse into a uniform transparent liquid, transfer it to a glass dish, dry it at 100°C, and bake it at 130°C for 30 minutes to obtain a foamed white modified polyethylene melamine salt PMAPVA. The rate is 94%. The infrared spectrum data of modified polyethylene melamine salt PMAPVA are as follows: 3620-3150, 2917, 2894, 1676, 1454, 1331, 1134, 1079, 982, 645. PMAPVA 1 H-NMR data: 1.4~1.5ppm (m, J=34.1Hz, 2H, CH 2 ) and 3.7~3.8ppm (d, J=23.3Hz, 1H), 4.7~6.2ppm (d, br, 2H), 7.1ppm.

[0045] Flame retardant finishing of fabrics:

[0046] Weigh 40g of PMAPVA and add it to 100 parts of water, fully stir a...

Embodiment 3

[0052] Synthesis of APPHPMC:

[0053] Weigh 60g of hydroxypropyl methylcellulose (HPMC) and moisten it with a small amount of water, add it to 200 parts of water, stir and dissolve it into a colorless transparent liquid at 90°C; add 15 parts of ammonium polyphosphate, and then add 5 parts Add urea into the mixture and stir thoroughly; disperse into a uniform transparent liquid, transfer to a glass dish and dry at 100°C, then bake at 130°C for 30 minutes to obtain foaming white modified hydroxypropyl methylcellulose APPHPMC with a yield of 97 %. The infrared spectrum data of APPHPMC are as follows: 3610-3130, 2918, 2896, 1684, 1465, 1327, 1154, 1083, 889, 765. APPHPMC's 1 H-NMR data: 1.3~1.5ppm (m, J=40.2Hz, 2H, CH 2 ) and 3.6~3.7ppm (d, J=28.4Hz, 1H), 4.8~6.3ppm (d, br, 2H), 7.3ppm.

[0054] Flame retardant finishing of fabrics:

[0055] Weigh 40g of APPHPMC and add it to 100 parts of water, fully stir and dissolve at 90°C; then add 3 parts of anionic surfactant, then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com