Extraction method of water-soluble humic acid

A water-soluble humic acid and extraction method technology, applied in fertilizer mixture, organic chemistry, fertilization equipment, etc., can solve the problems of low extraction rate of water-soluble humic acid, unfavorable industrial production, single activator, etc., to enhance crop resistance High efficiency, obvious effect of increasing production, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

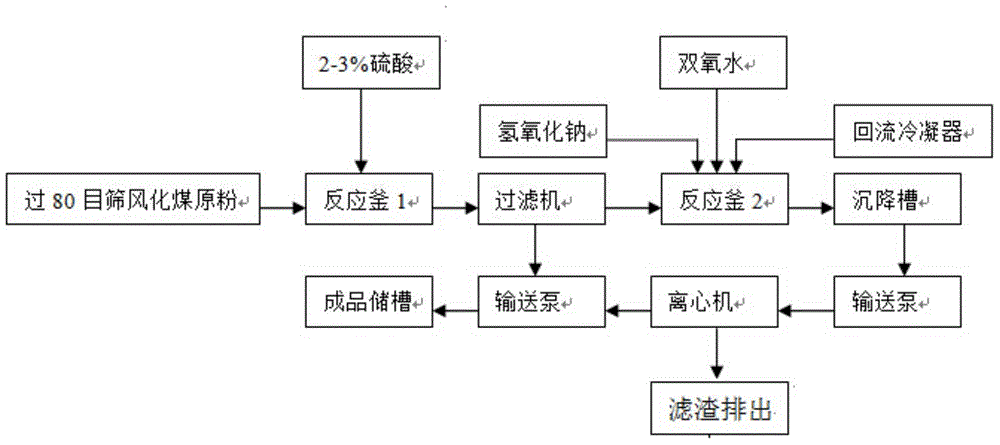

[0022] A kind of extraction method of water-soluble humic acid, such as figure 1 As shown, add humic acid raw powder into the reaction kettle, pickle with sulfuric acid solution with a volume fraction of 2%, remove calcium and magnesium ions; add sodium hydroxide solution with a volume fraction of 4%, slowly add a volume fraction of 30% The hydrogen peroxide was subjected to oxidation and alkali extraction, and reacted at 80°C for 60 minutes while stirring at a speed of 500 r / min until the pH of the final solution was 8 to obtain water-soluble humic acid.

Embodiment 2

[0024] A kind of extraction method of water-soluble humic acid, such as figure 1 As shown, put the original humic acid powder into the reaction kettle, pickle with a sulfuric acid solution with a volume fraction of 3%, and remove calcium and magnesium ions; add a sodium hydroxide solution with a volume fraction of 5%, and then slowly add a volume fraction of 35% hydrogen peroxide, carry out oxidation and alkali extraction, react at 90°C for 90 minutes, and stir at the same time, the rotation speed is 600r / min, until the pH value of the final solution is 10, and water-soluble humic acid is obtained.

Embodiment 3

[0026] A kind of extraction method of water-soluble humic acid, such as figure 1 As shown, put the original humic acid powder into the reaction kettle, pickle with a sulfuric acid solution with a volume fraction of 2.5%, and remove calcium and magnesium ions; add a sodium hydroxide solution with a volume fraction of 4.5%, and then slowly add a volume fraction of 32% hydrogen peroxide, carry out oxidation and alkali extraction, react at 85°C for 75 minutes, and stir at the same time, the rotation speed is 550r / min, until the final pH value of the solution is 9, and water-soluble humic acid is obtained.

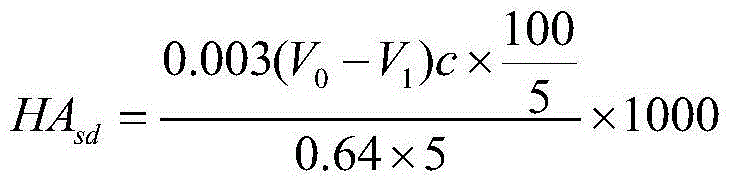

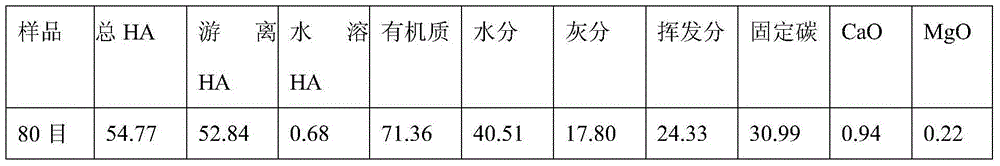

[0027] (1) Determination of Soluble Humic Acid Content in Activation Filtrate of Weathered Coal

[0028] The determination of humic acid must be under strong acidic conditions. Potassium dichromate can oxidize the carbon in humic acid to carbon dioxide, and then it can be analyzed and determined. What get when adopting HG / T 3278-2011 sodium humate line standard to measure is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com