Environment-friendly lubricating oil taking bio-oil as base oil and preparation method of lubricating oil

A bio-oil and lubricating oil technology, which is applied in lubricating compositions and the petroleum industry, can solve the problems of poor compatibility of vegetable oil anti-oxidation stability additives, application limitations, investment limitations in preparation process equipment, and large-scale promotion of base oils. Enhance dispersibility and anti-oxidation stability, maintain social benefits, and have good and stable lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

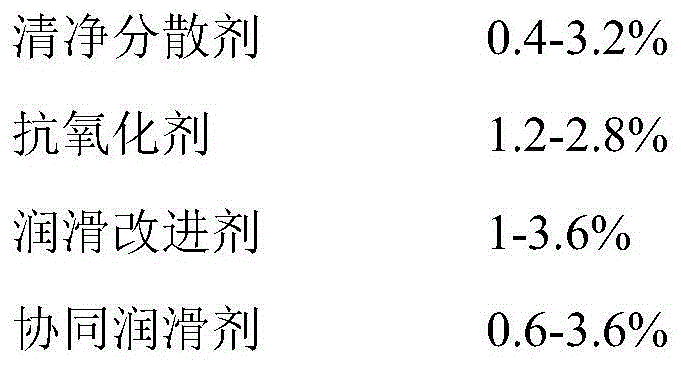

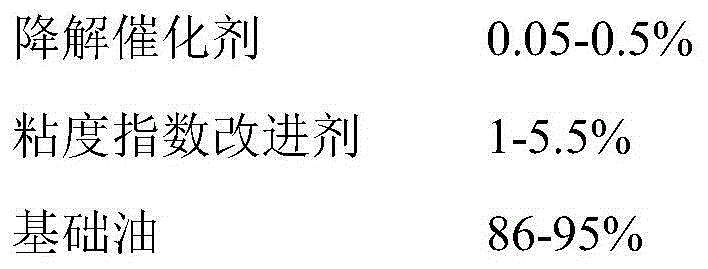

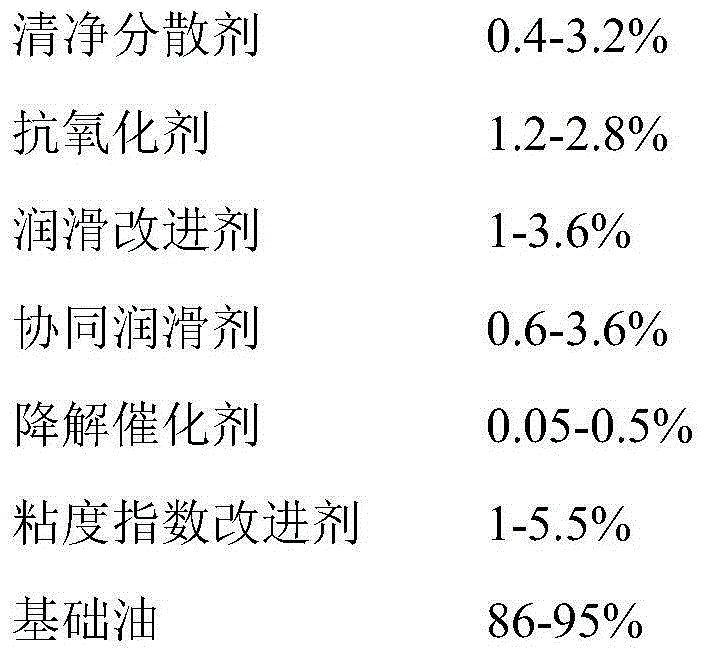

Method used

Image

Examples

example 1

[0017] Example 1: Take 88.6g bio-oil, add 2.0g ZSM-5 zeolite molecular sieve and 4.0g clay respectively, stir at 70°C for 4 hours, filter to remove solid particles in the oil, and complete the refinement; mix succinimide with Tween 80 Add 1.2g of the mixture with a mass ratio of 1:1 to the refined bio-oil, stir evenly, then add 1.6g of 2,5-di-tert-butylhydroquinone, continue stirring evenly, and raise the temperature of the system to 105°C , keep warm for 30min, and complete the dehydration; lower the temperature of the dehydrated bio-oil to 55°C and stir at a constant temperature, mix 2.4g of inorganic fullerene molybdenum disulfide with a particle size of 80-110nm, 0.6g of single-layer graphene, and 0.1g of Titanium dioxide with a diameter of 50-80nm and 5.5g of polymethacrylate with a Z-average molecular weight of 68,000 were added to the bio-oil in sequence. Each time an additive was added, it was first stirred at 400rpm for 6min, and then the next additive was added. Afte...

example 2

[0018] Example 2: Take 92g bio-oil, add 2.2g ZSM-5 zeolite molecular sieve and 3.6g clay respectively, stir at 75°C for 3 hours, filter to remove solid particles in the oil, and complete the refinement; mix succinimide with Tween 80 mass Add 0.6g of the mixture with a ratio of 1:2 to the refined bio-oil, stir evenly, then add 1.2g of 2,5-di-tert-butyl-3-methylhydroquinone, continue stirring evenly, and mix the system Raise the temperature to 110°C, keep it warm for 25 minutes, and complete the dehydration; lower the temperature of the dehydrated bio-oil to 50°C and stir at a constant temperature, mix 1.6g of inorganic fullerene molybdenum disulfide with a particle size of 50-70nm, and 1.2g of single-layer graphene , 0.2g of titanium dioxide with a particle size of 50-80nm, and 3.2g of polymethacrylate with a Z-average molecular weight of 68,000 were added to the bio-oil successively, wherein, each time an additive was added, it was first stirred at 600rpm for 5min, Add the nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com