Bacterial strain capable of producing chitinase and application of bacterial strain to production of chitinase by fermenting crab shell

A chitinase and strain technology, applied in the directions of enzymes, enzymes, bacteria, etc., can solve the problems of restricting the large-scale use of chitinase, high production cost of enzyme preparations, and insufficient activity to meet the needs of industrialization, and achieve significant economic benefits and Environmental benefits, low production costs, and efficient hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for producing chitinase by fermentation of crab shells includes the following steps:

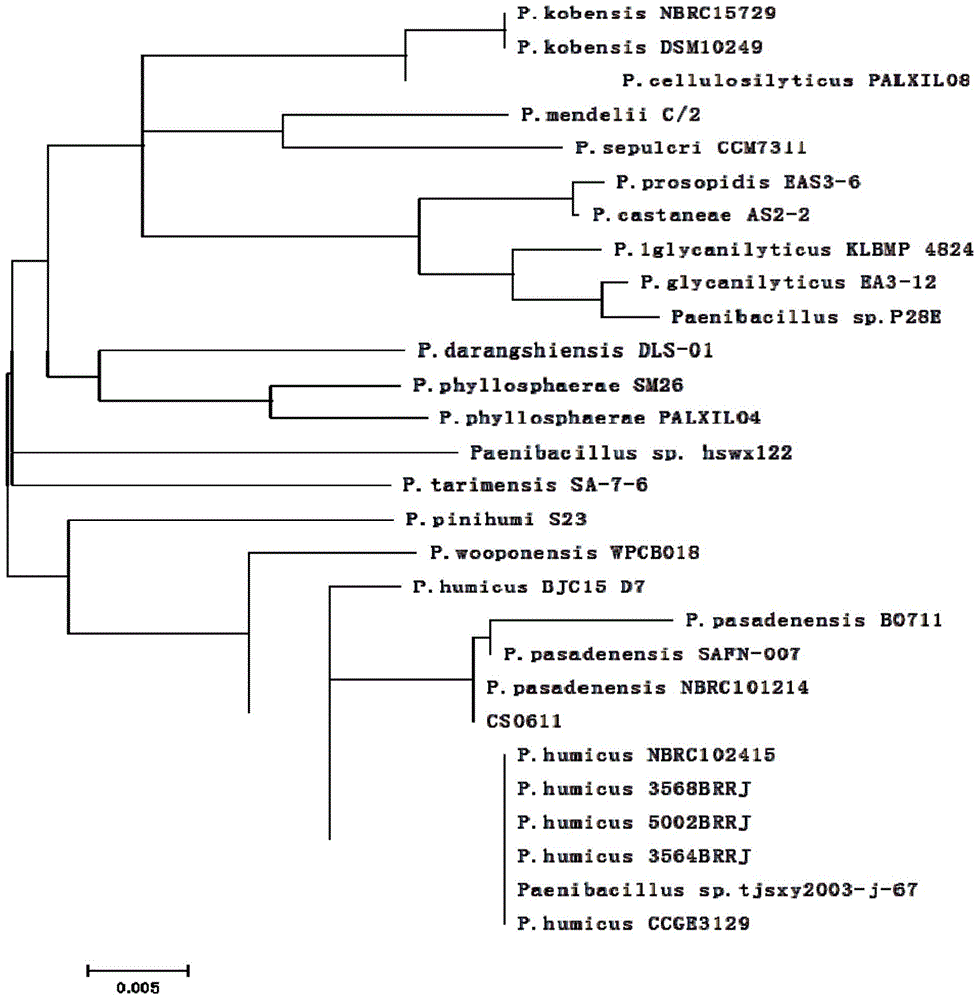

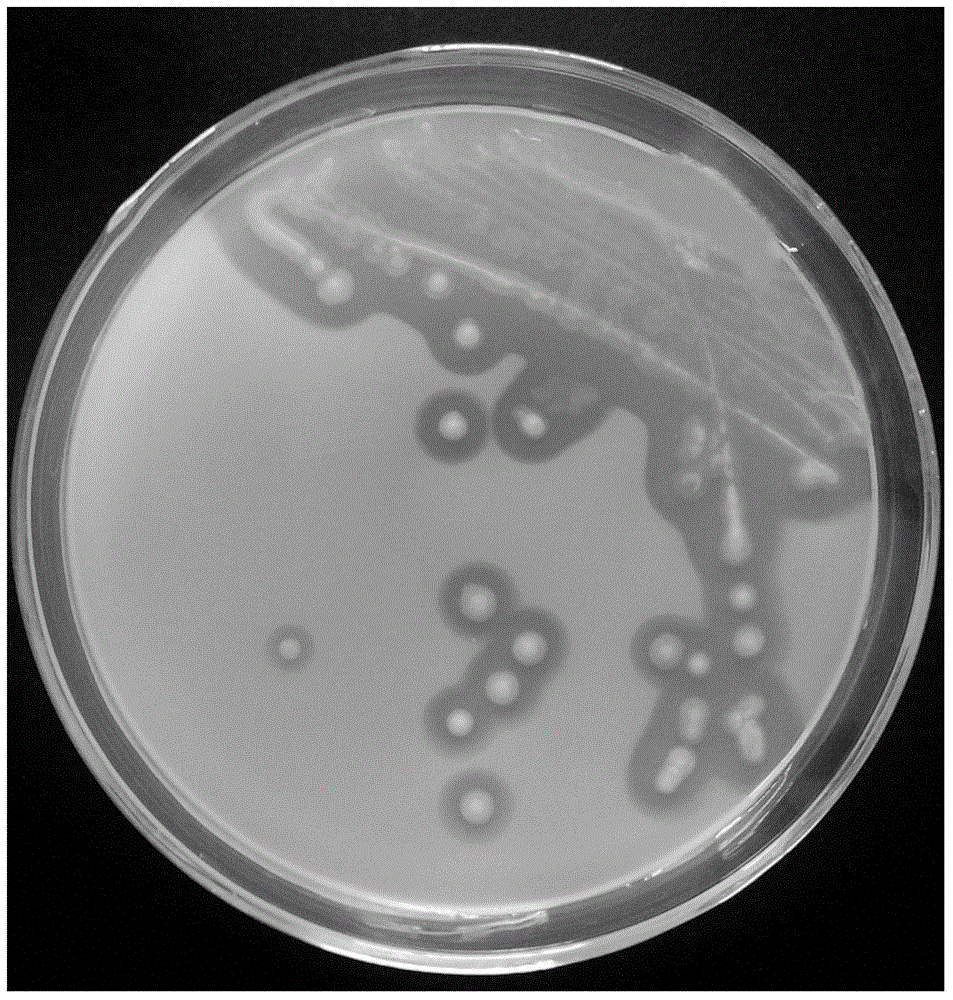

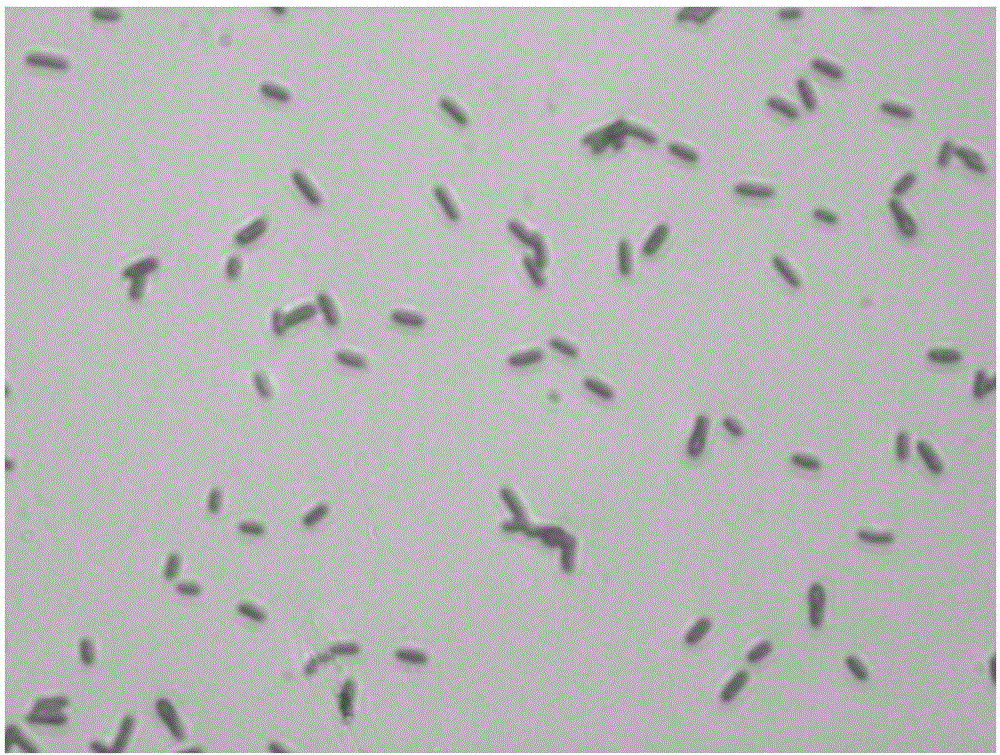

[0035] (1) Activation of Paenibacillus pasadenensis CS0611 Take the slant culture and place it in a 37°C constant temperature incubator for 30 minutes to activate the strain.

[0036] (2) Seed liquid culture

[0037] An appropriate amount of the slant culture was inoculated into the seed medium, and the seed medium was LB medium, which consisted of: tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, pH 7.0. The culture conditions were 37°C, the rotating speed of the shaker was 180 rpm, and the culture time was 20 h.

[0038] (3) Liquid fermentation culture

[0039] Transfer the seed liquid to the fermentation medium with an inoculum of 4%. The fermentation medium consists of: crab shell powder 10g / L, dipotassium hydrogen phosphate 0.08 g / L, potassium dihydrogen phosphate 0.02 g / L, and magnesium sulfate 0.04 g / L, sodium chloride 0.1g / L. The culture conditions were 30°C, the r...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is:

[0045] Liquid fermentation culture

[0046] The composition of the enzyme production medium is: crab shell powder 10g / L, dipotassium hydrogen phosphate 0.07 g / L, potassium dihydrogen phosphate 0.03 g / L, magnesium sulfate 0.05 g / L, and sodium chloride 0.1 g / L. The inoculation amount is 6%, the culture condition is 30°C, the rotation speed of the shaker is 200 rpm, and the culture time is 48 hours.

[0047] After the fermentation is completed under the above conditions, the supernatant of the fermentation broth is centrifuged to obtain the crude chitinase enzyme solution, and the enzyme activity can reach 205.4mU / mL.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is:

[0050] Liquid fermentation culture

[0051] The composition of the enzyme production medium is: crab shell powder 10g / L, dipotassium hydrogen phosphate 0.08 g / L, potassium dihydrogen phosphate 0.02 g / L, magnesium sulfate 0.04 g / L, and sodium chloride 0.1 g / L. The inoculum amount is 5%, the culture condition is 30°C, the rotation speed of the shaker is 180 rpm, and the culture time is 72 hours.

[0052] After the fermentation is completed under the above conditions, the supernatant of the fermentation broth is centrifuged to obtain the crude chitinase enzyme solution, and the enzyme activity can reach 200.2mU / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com