VHG ethanol fermentation technology by using surfactant and water as media

A surfactant, ethanol fermentation technology, applied in the direction of fermentation, microorganism-based methods, microorganisms, etc., can solve the problems of increased energy consumption, prolonged fermentation time, incomplete fermentation, etc., to reduce glucose concentration, improve fermentation efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

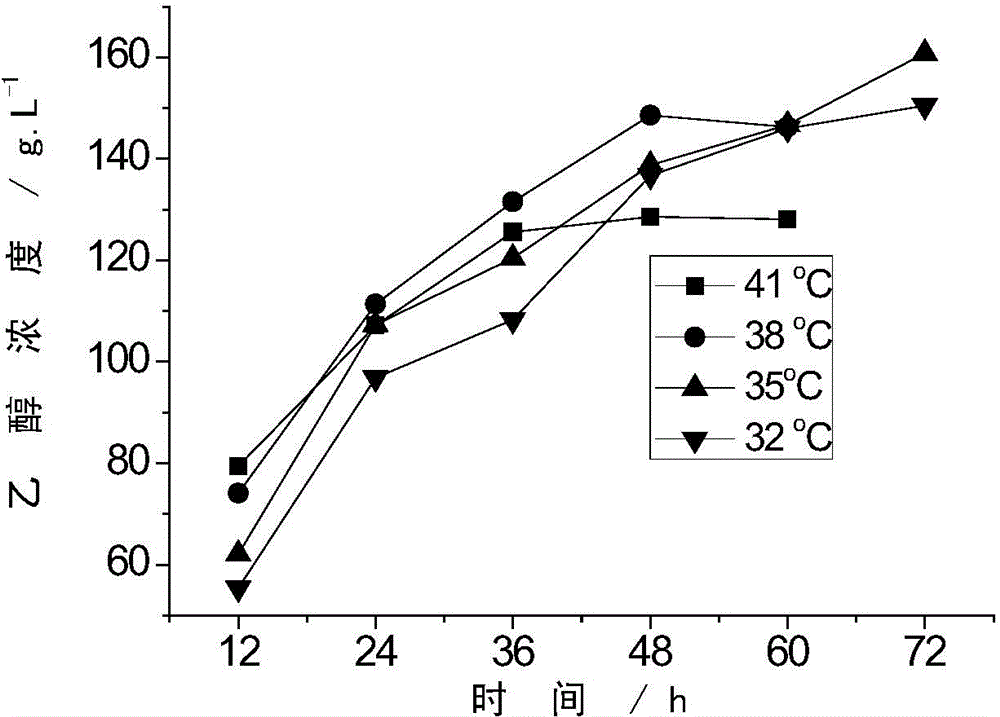

[0039] First, weigh 0.4g of Saccharomyces cerevisiae and place it in a 100mL Erlenmeyer flask, rehydrate and activate it with 4mL of ultrapure water at 38°C for 20min, then it can be used as distiller's mother. Then add 6.0g of glucose, PEG-200 (according to the dosage in Table 1) (1-8g), pre-configured H 2 SO 4 The solution (consumption according to Table 1) was sealed with a plastic wrap, and placed in a shaker for 48 hours at 38° C. with shaking at a speed of 160 r / min. It can be seen from the data in Table 1 that when PEG-200 is not added to the fermentation system (Example 1), the conversion rate of glucose is 96%, the yield of ethanol is 81%, and the concentration of ethanol is 112g L -1 , and when 1.0g PEG-200 was used to replace the pH solution, the glucose conversion rate increased to 99%, the ethanol yield increased to 88%, and the ethanol concentration increased to 129g L -1 , with the increase of the amount of PEG-200, the glucose conversion rate, ethanol yield a...

Embodiment 10-17

[0043] Weigh 0.4g of yeast into a 100mL Erlenmeyer flask, rehydrate and activate with 4mL ultrapure water at 38°C for 20min, and then use it as distiller's mother. Then add 6.0g glucose, PEG-400 (according to the dosage in Table 2) (1-8g), pre-configured H 2 SO 4 The solution (consumption according to Table 2) was sealed with a plastic wrap, and placed in a shaker for 48 hours at 38° C. with shaking at a speed of 160 r / min. It can be seen from the data in Table 2 that when 4.0g PEG-400 is used to replace the pH solution, the ethanol concentration can reach 150g L -1 , and almost no residual sugar remains in the fermentation system. These results further prove that PEG can replace water as a fermentation medium within a certain proportion, increase the concentration of ethanol at the end of fermentation, reduce the residual glucose content at the end of fermentation, reduce water consumption, reduce production costs, and improve fermentation efficiency.

[0044] Table 2. Eff...

Embodiment 18-25

[0047] Weigh 0.4g of yeast into a 100mL Erlenmeyer flask, rehydrate and activate with 4mL ultrapure water at 38°C for 20min, and then use it as distiller's mother. Then add 6.0g of glucose, PEG-600 (according to the dosage in Table 3) (1-8g), pre-configured H 2 SO 4 The solution (consumption according to Table 3) was sealed with a plastic wrap, and placed in a shaker for 48 hours at 38° C. with shaking at a speed of 160 r / min. It can be seen from the data in Table 3 that when PEG-600 is used to replace the pH solution, the ethanol concentration gradually increases and then decreases with the increase of the amount of PEG-600, and the highest ethanol concentration can reach 150g L -1 . These results fully prove that PEG can replace water as a fermentation medium within a certain proportion, increase the concentration of ethanol at the end of fermentation, reduce the residual glucose content at the end of fermentation, reduce water consumption, reduce production costs, and imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com