Method for preparing glassy carbon electrode modified by noncovalent-functionalized graphene and ionic liquid compound

A technology of glassy carbon electrodes and ionic liquids, which is applied in the field of preparation of glassy carbon electrodes modified by non-covalent functionalized graphene ionic liquid composites, can solve the problems of cumbersome operation steps and expensive instruments, and achieve good application prospects and detection The effect of limiting the minimum and reducing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

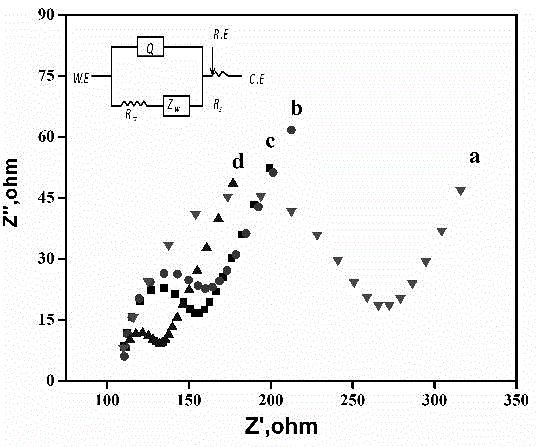

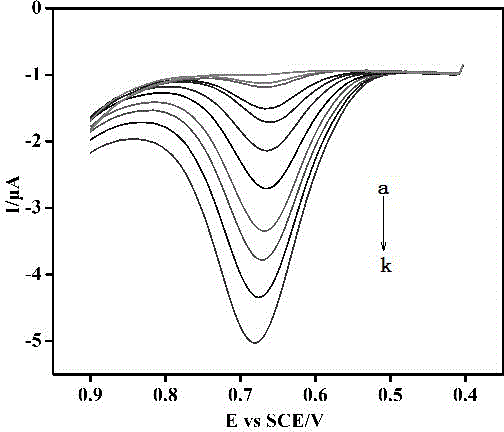

[0032] A preparation method of a non-covalent functionalized graphene ionic liquid composite modified glassy carbon electrode, comprising the following steps:

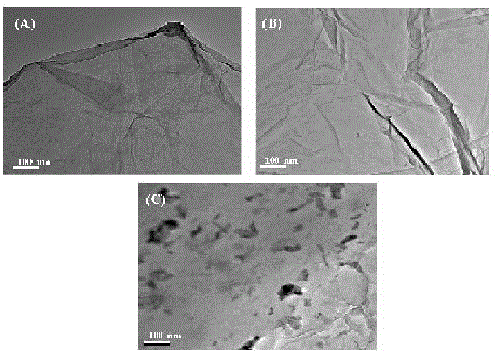

[0033] a. Mix 10mg graphene oxide and 5mM sodium dodecylbenzenesulfonate (SDBS), stir with a magnetic stirrer at room temperature for half an hour, transfer the mixture to a single-necked flask, add 200uL hydrazine, and stir with a constant temperature magnetic stirrer Heated and stirred at 80°C for 24 hours, then centrifuged in a centrifuge, rinsed with distilled water three times, and dried at 60°C to obtain SDBS-functionalized graphene (SDBS-Gr).

[0034] Dissolve 1g chitosan with 0.10M 100mL glacial acetic acid to obtain 1% chitosan aqueous solution (CS), then dissolve 1mg SDBS-Gr synthesized in step a into 5mL chitosan, ultrasonicate for half an hour, and filter under reduced pressure with a vacuum pump , then rinsed with distilled water three times, and dried at 60°C to obtain SDBS-Gr-CS. Finally, add 20 μL ioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com