Preparation method of carbon nano tube-modified layered lithium-enriched high-manganese positive electrode material

A carbon nanotube modification and positive electrode material technology, which is applied in battery electrodes, electrical components, circuits, etc., to achieve the effects of good cycle performance, fast charging speed, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

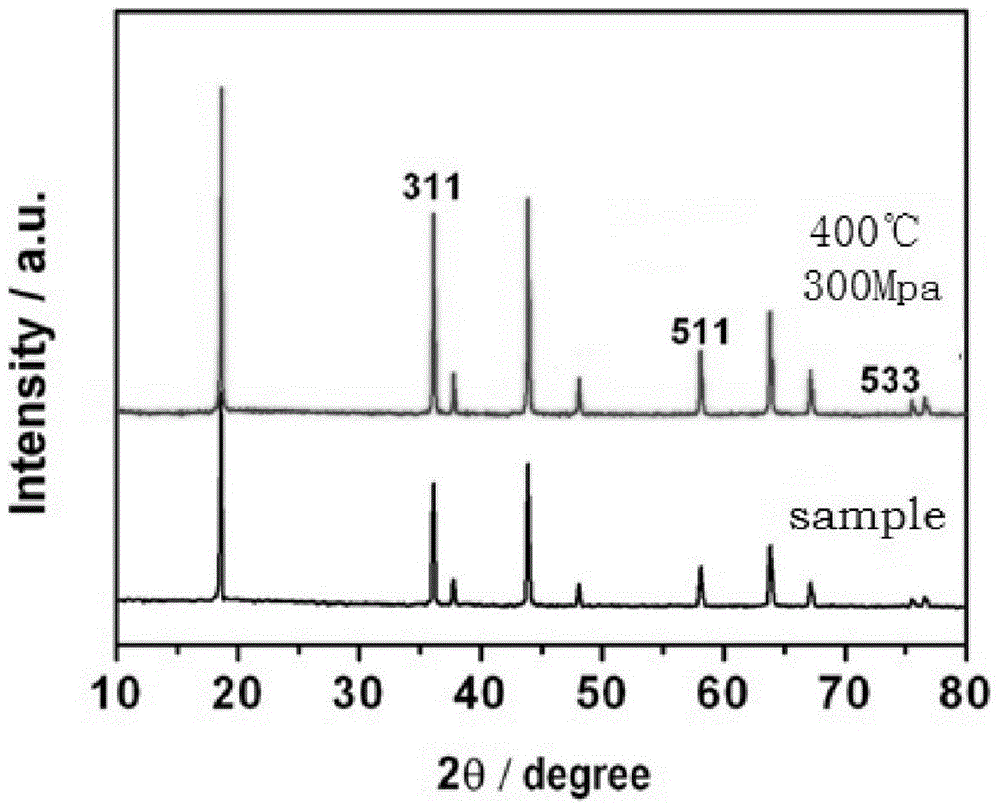

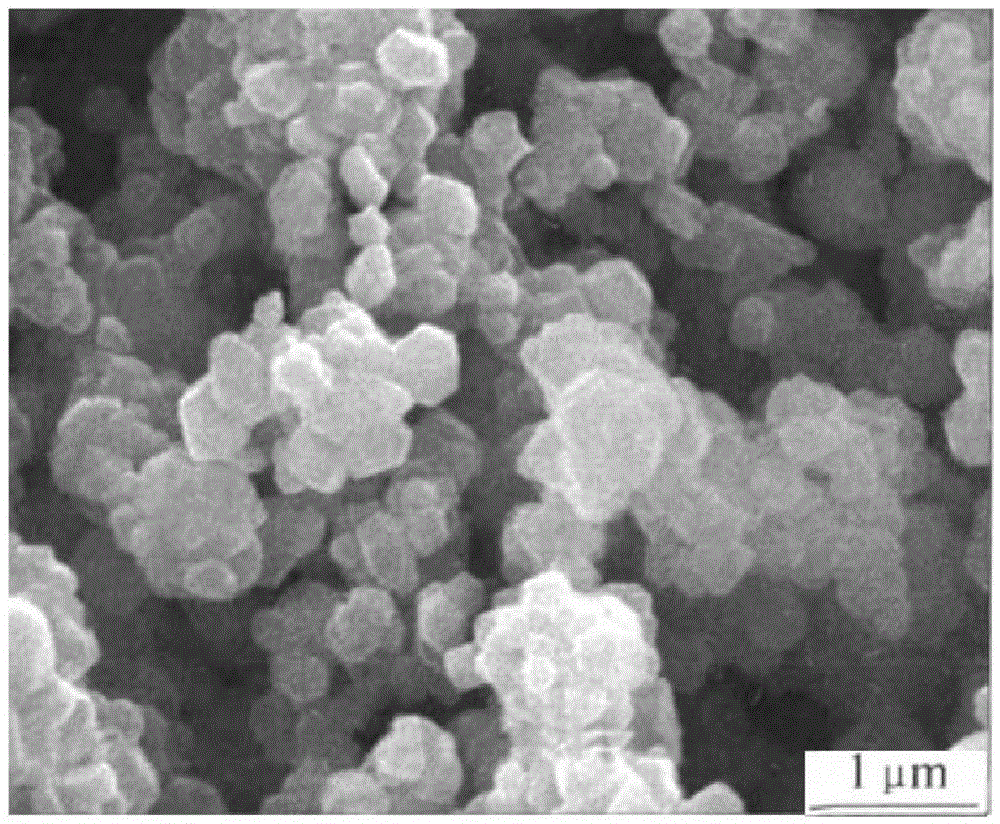

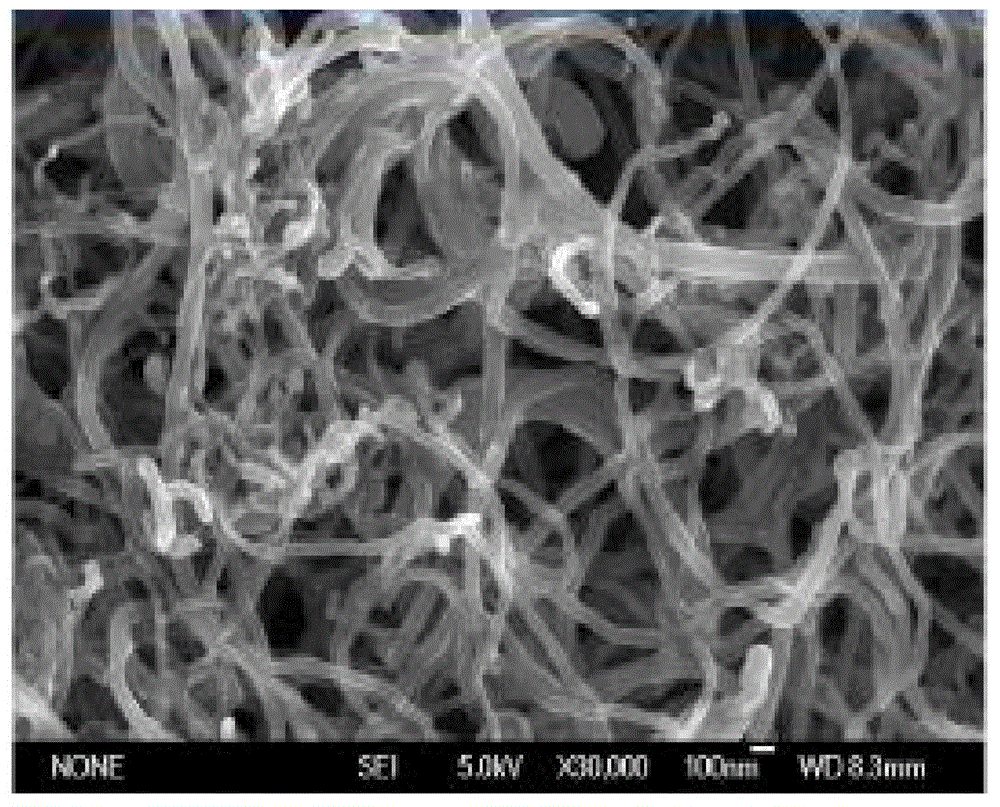

[0030] Take lithium carbonate 8.62g, manganese carbonate 13.34g and nickel carbonate 5.94g respectively according to general formula metering ratio and mix and form mixture, described mixture is placed in agate mortar, adds dehydrated alcohol and carries out wet grinding to form homogeneous mixture, The uniformly ground mixture is vacuum-dried, and sintered at a temperature of 800° C. to form a bulk phase doped body. The bulk phase doped body is wet ground and dried to form a bulk phase doped powder. The bulk-phase doped powder is dispersed in the aluminum nitrate solution, ammonia water is added to adjust the pH value of the solution, the solution is dried and then ground, and then heat-treated at 400°C to form a precursor, and the obtained precursor is heated under a pressure of 100Mpa Hold the pressure for 2 minutes to form a green body, place the green body in the pyrophyllite cavity of the hot isostatic pressing equipment, heat and hold the pressure for 0.5 hours at a temp...

Embodiment 2

[0033] Take lithium carbonate 8.62g, manganese carbonate 13.34g and nickel carbonate 5.94g respectively according to general formula metering ratio and mix and form mixture, described mixture is placed in agate mortar, adds dehydrated alcohol and carries out wet grinding to form homogeneous mixture, The uniformly ground mixture is vacuum-dried, and sintered at a temperature of 800° C. to form a bulk phase doped body. The bulk phase doped body is wet ground and dried to form a bulk phase doped powder. The bulk-phase doped powder is dispersed in the aluminum nitrate solution, ammonia water is added to adjust the pH value of the solution, the solution is dried and then ground, and then heat-treated at 400°C to form a precursor, and the obtained precursor is heated under a pressure of 100Mpa Hold the pressure for 2 minutes to form a green body, place the green body in the pyrophyllite cavity of the hot isostatic pressing equipment, heat and hold the pressure for 0.5 hours at a temp...

Embodiment 3

[0036] Take lithium carbonate 8.62g, manganese carbonate 13.34g and nickel carbonate 5.94g respectively according to general formula metering ratio and mix and form mixture, described mixture is placed in agate mortar, adds dehydrated alcohol and carries out wet grinding to form homogeneous mixture, The uniformly ground mixture is vacuum-dried, and sintered at a temperature of 800° C. to form a bulk phase doped body. The bulk phase doped body is wet ground and dried to form a bulk phase doped powder. The bulk-phase doped powder is dispersed in the aluminum nitrate solution, ammonia water is added to adjust the pH value of the solution, the solution is dried and then ground, and then heat-treated at 400°C to form a precursor, and the obtained precursor is heated under a pressure of 100Mpa Hold the pressure for 2 minutes to form a green body, place the green body in the pyrophyllite cavity of the hot isostatic pressing equipment, heat and hold the pressure for 0.5 hours at a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com