Spherical composite positive pole material for lithium sulfur battery and preparation method and application of spherical composite positive pole material

A composite positive electrode material, lithium-sulfur battery technology, applied in the field of electrochemical energy storage, can solve the problems of low cycle stability and capacity retention, low battery energy density, poor battery stability, etc., to improve cycle stability and capacity retention efficiency, reduce process costs, and improve consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

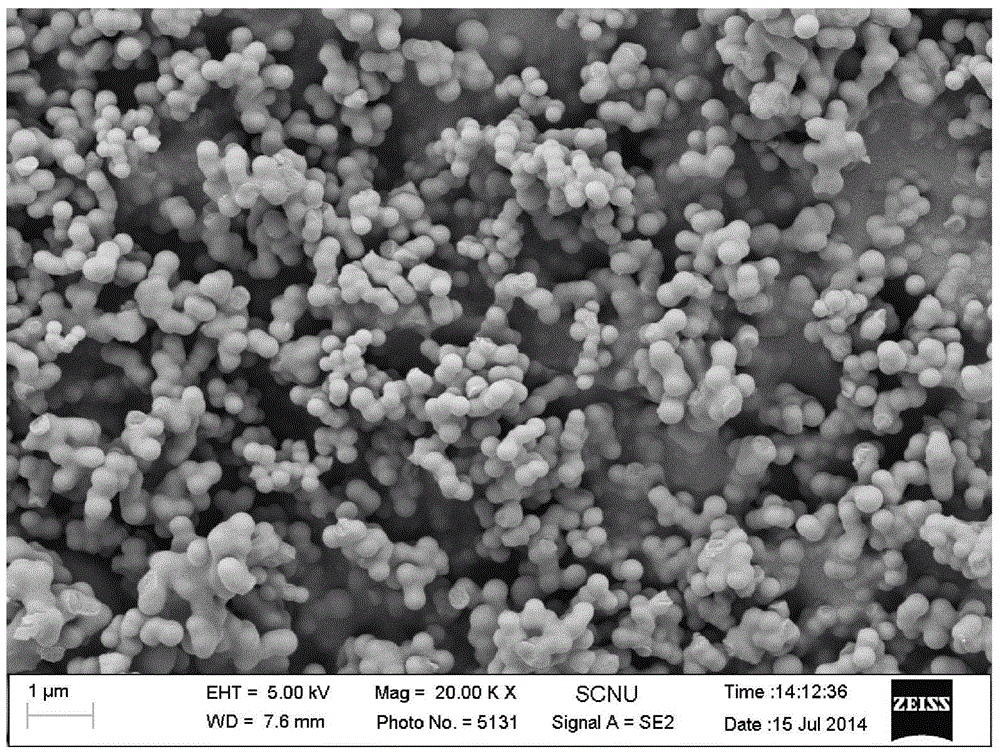

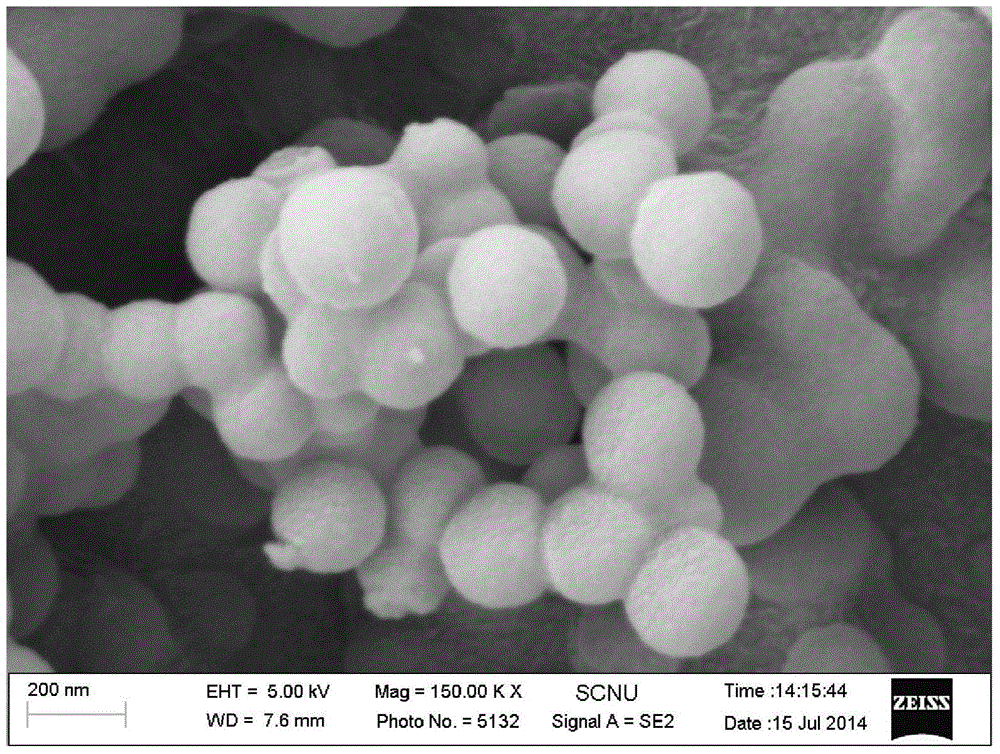

[0071] A kind of porous carbon nanosphere, its preparation method is as follows:

[0072] (a) Dissolve 8.0g of glucose in 80mL of deionized water to prepare a colorless and transparent solution of 0.56mol / L, then add it into a hydrothermal reaction kettle with a capacity of 80mL, seal it, heat to 180°C, keep the temperature for 10h, and cool naturally to Room temperature; (b) filter the reaction solution obtained in step (a), wash the filtered precipitate with absolute ethanol and deionized water several times, and dry it with air at 80°C for 24 hours; (c) dissolve 1.08g of zinc chloride in 40mL of deionized water was prepared into a milky white flocculent turbid liquid; (d) 0.5091 g of the precipitated product obtained in step (b) was dried and added to the milky white flocculent turbid liquid prepared in step (c), and ultrasonically dispersed for 6 hours to obtain a turbid liquid; (e ) heating the turbid liquid obtained in step (d) to 120° C. to evaporate to dryness to obtai...

Embodiment 2

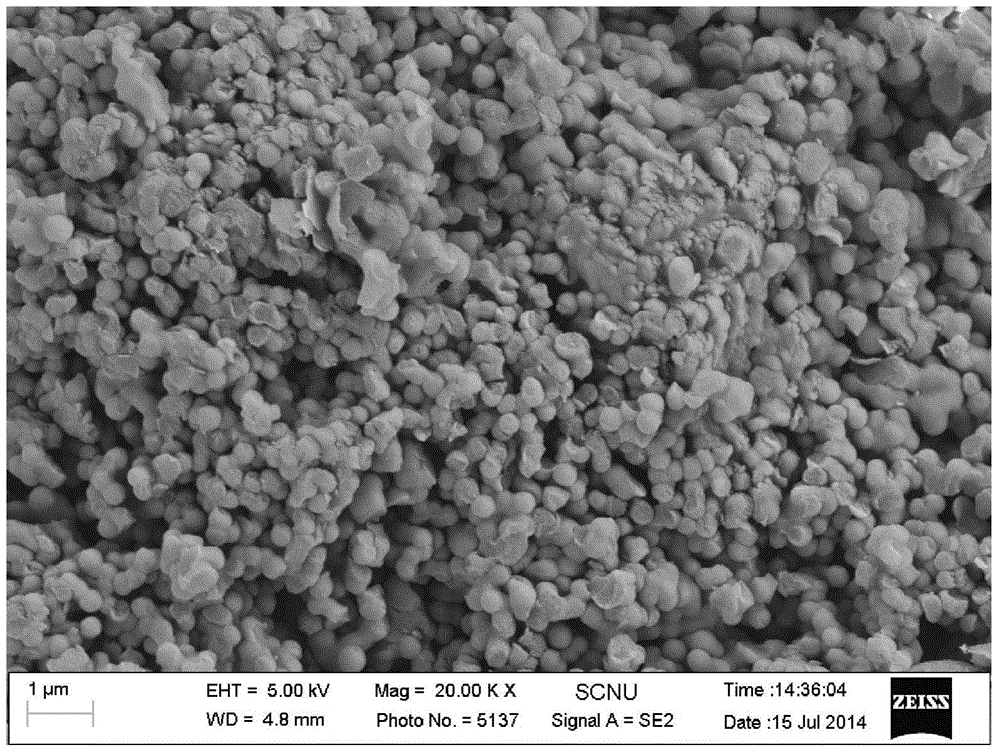

[0074] A kind of porous carbon nanosphere, its preparation method is as follows:

[0075] (a) Dissolve 8.0g of glucose in 80mL of deionized water to prepare a colorless and transparent solution of 0.56mol / L, then add it into a hydrothermal reaction kettle with a capacity of 80mL, seal it, heat to 180°C, keep the temperature for 10h, and cool naturally to room temperature; (b) filter the reaction solution obtained in step (a), wash the filtered precipitate with absolute ethanol and deionized water for several times, and dry it with air at 80°C for 24 hours; (c) dissolve 2.07g of zinc chloride in 40mL of deionized water was prepared into a milky white flocculent turbid liquid; (d) 0.5061 g of the precipitated product obtained in step (b) was dried and added to the milky white flocculent turbid liquid prepared in step (c), and ultrasonically dispersed for 6 hours to obtain a turbid liquid; (e ) heating the turbid liquid obtained in step (d) to 120° C. to evaporate to dryness to o...

Embodiment 3

[0077] A kind of porous carbon nanosphere, its preparation method is as follows:

[0078] (a) Dissolve 8.0g of glucose in 80mL of deionized water to prepare a colorless and transparent solution of 0.56mol / L, then add it into a hydrothermal reaction kettle with a capacity of 80mL, seal it, heat to 180°C, keep the temperature for 10h, and cool naturally to room temperature; (b) filter the reaction solution obtained in step (a), wash the filtered precipitate with absolute ethanol and deionized water for several times, and dry at 80°C for 24 hours; (c) dissolve 3.05g of zinc chloride in 40mL of deionized water was prepared into a milky white flocculent turbid liquid; (d) 0.5032 g of the precipitated product obtained in step (b) was dried and added to the milky white flocculent turbid liquid prepared in step (c), and ultrasonically dispersed for 6 hours to obtain a turbid liquid; (e ) heating the turbid liquid obtained in step (d) to 120° C. to evaporate to dryness to obtain a soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com