Electrolyte and lithium ion battery using same

A technology of electrolyte and lithium salt, which is applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve problems such as loss, and achieve the effect of ensuring high temperature performance and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Electrolyte L1 # ~L13 # preparation of

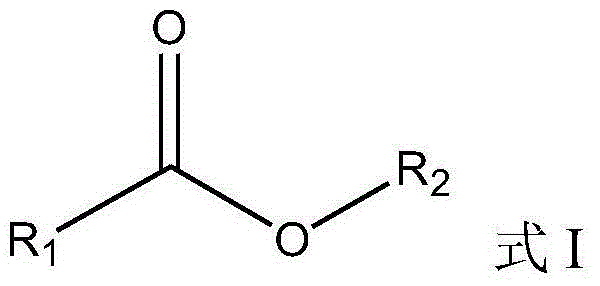

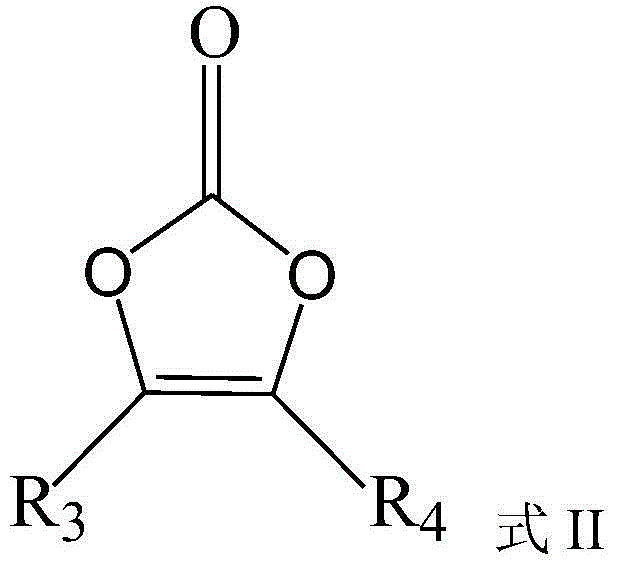

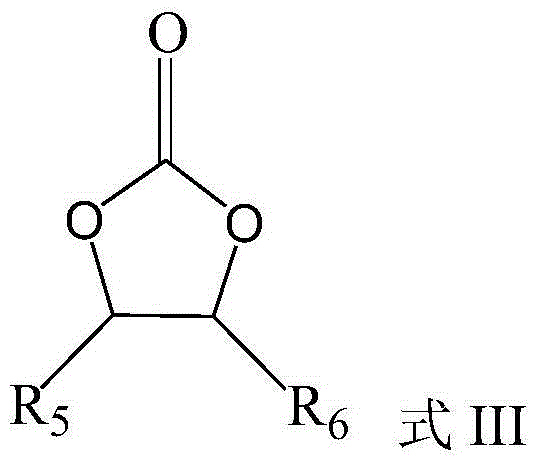

[0046] The preparation steps of the electrolyte are: mix ethylene carbonate and diethyl carbonate at a volume ratio of 1:2, add chain carbonate, cyclic carbonate containing C=C double bond in chemical structure formula, and other additives , after mixing well, add LiPF 6 , to get LiPF 6 A solution with a concentration of 1 mol / L is the electrolyte.

[0047]The numbering of gained electrolytic solution and electrolytic solution form (the kind of chain carbonate and the mass percent composition in electrolytic solution, the kind and the quality of the cyclic carbonate that contains C=C double bond in the chemical structural formula percentage content, whether to add additives, and the mass percentage content of additives in the electrolyte) are shown in Table 1.

Embodiment 2

[0053] Example 2 Battery C1 # ~C13 # 、DC1 # ~DC8 # production

[0054] Production of the positive electrode sheet:

[0055] The positive electrode active material lithium cobaltate (molecular formula is LiCoO 2 ), the conductive agent acetylene black, and the binder polyvinylidene fluoride (abbreviated as PVDF) are fully stirred and mixed in an appropriate amount of N-methylpyrrolidone (abbreviated as NMP) solvent in a weight ratio of 96:2:2 to form Uniform cathode slurry. The slurry was coated on the positive electrode current collector Al foil, dried and cold pressed to obtain the positive electrode sheet.

[0056] Production of negative electrode sheet:

[0057] Negative electrode active material graphite, conductive agent acetylene black, binder styrene-butadiene rubber (abbreviated as SBR), thickener sodium carboxymethyl cellulose (abbreviated as CMC) in an appropriate amount according to the weight ratio of 95:2:2:1 Fully stir and mix in the deionized water solve...

Embodiment 3

[0062] Example 3 Battery High Temperature Storage Performance Test

[0063] Respectively to the lithium ion battery C1 obtained in embodiment 2 # ~C13 # , battery DC1 # ~DC8 # To test the high temperature storage performance, the method is as follows:

[0064] At 25°C, first charge the lithium-ion secondary battery C1 with a constant current of 0.5C. # ~C13 # 、DC1 # ~DC8 # Charge to the charge cut-off voltage of 4.35V, charge at a constant voltage of 4.35V to a current of 0.025C, and then discharge to 3.0V at a rate of 0.5C. The discharge capacity is recorded as the discharge capacity of the battery before storage. Afterwards, charge to 4.35V with a constant current at a rate of 0.5C, and then charge at a constant voltage of 4.35V to a current of 0.025C, so that it is fully charged at 4.35V, and test the thickness and internal resistance of the battery before storage; then, put it in 85°C In the incubator, take it out after 24 hours of storage, test its thickness again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com