Lithium ion battery non-aqueous electrolyte, lithium ion battery and preparation method of lithium ion battery non-aqueous electrolyte

A lithium-ion battery and non-aqueous electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as increased battery expansion, potential safety hazards, and serious gas production during storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Embodiment: the present invention provides a kind of non-aqueous electrolytic solution of lithium ion battery, comprise electrolyte lithium salt, non-aqueous organic solvent and additive, by the mass percentage content in the non-aqueous electrolytic solution of lithium ion battery, described additive comprises Part A, component B and component C, the component A is 0.1%-3%; the component B is 10%-80%; the component C is 0.1%-3%;

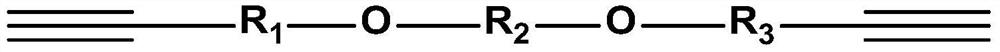

[0052] The component A is a substance represented by the following structural formula (1),

[0053]

[0054] The component B is one or more of the substances represented by the following structural formula (2), structural formula (3), structural formula (4) or structural formula (5),

[0055] The structural formula (2) is R4-COO-R5; the structural formula (3) is R6-OCOO-R7;

[0056] The structural formula (4) is R8-O-R9;

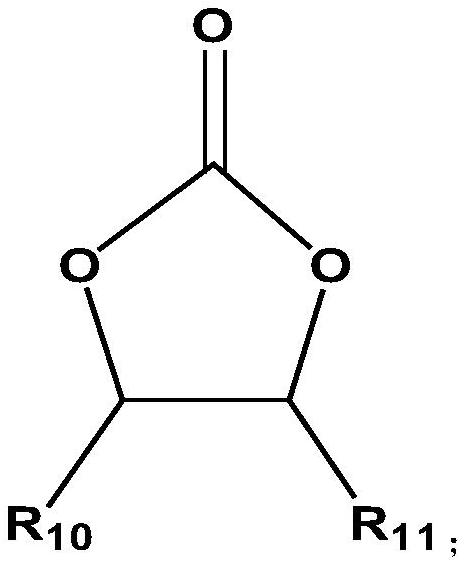

[0057] Described structural formula (5) is

[0058]

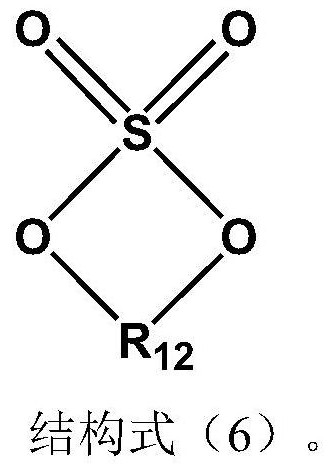

[0059] The component C is a substance represented by struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com