Solid electrolytic capacitor and manufacturing method thereof

A technology of solid electrolysis and solid electrolyte layer, applied in the direction of solid electrolytic capacitors, electrolytic capacitor manufacturing, electrolytic capacitors, etc., to achieve high withstand voltage characteristics, ensure charge and discharge performance, and prevent deterioration of withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

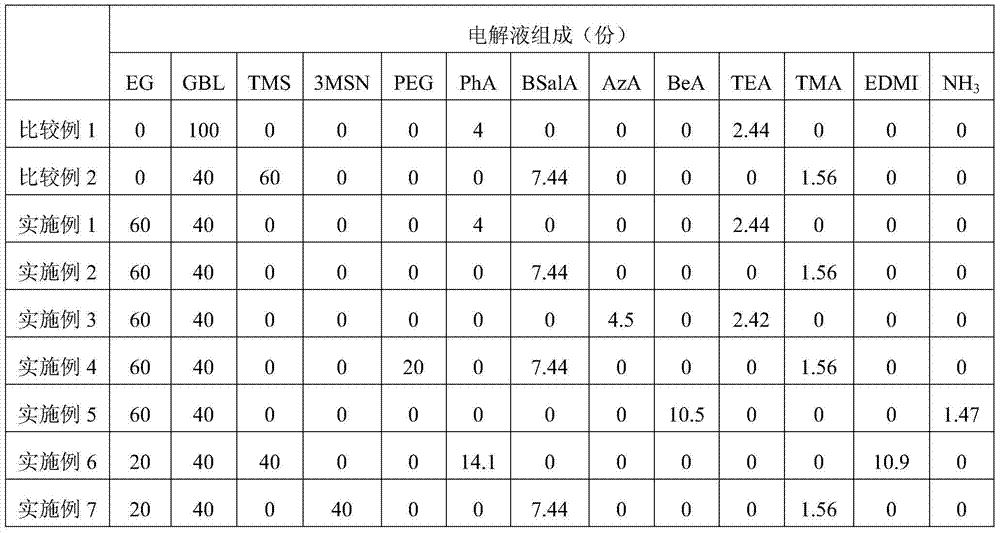

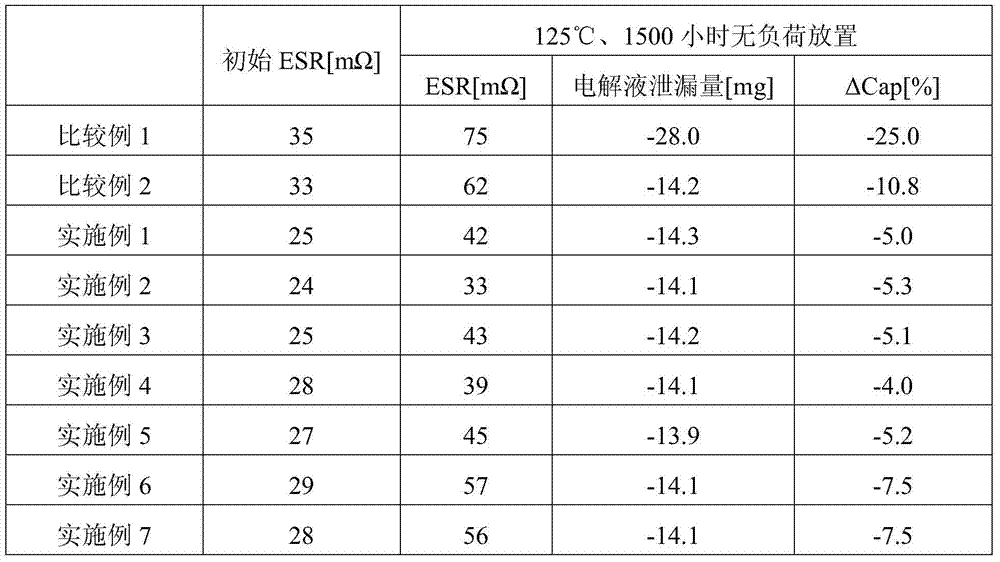

[0046] Next, the present invention will be described in more detail based on Examples and Comparative Examples manufactured as follows.

[0047] First, the anode foil and the cathode foil with the oxide film layer formed on the surface were connected to the electrode lead-out member, and the two electrode foils were wound through a separator to form a capacitor element with an element shape of 6.3φ×6.1L. Next, the capacitor element was immersed in an aqueous solution of ammonium dihydrogen phosphate for 40 minutes to perform repair chemical conversion. Then, the conductive polymer compound dispersion obtained by dispersing fine particles of PEDOT and polystyrenesulfonic acid in an aqueous solution was immersed, and the capacitor element was pulled up and dried at about 150°C. Furthermore, the immersion-drying in which the capacitor element is immersed in the conductive polymer compound dispersion is repeated several times to form a conductive polymer layer made of a conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com