A kind of preparation method and device of chlorine trifluoride

A technology of chlorine trifluoride and chlorine gas, which is applied in the direction of interhalogen compounds, can solve the problems of restricting the industrialization scale of chlorine trifluoride, complex production process, and low reliability of equipment, and shorten the reaction time and lower the reaction temperature , The effect of increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

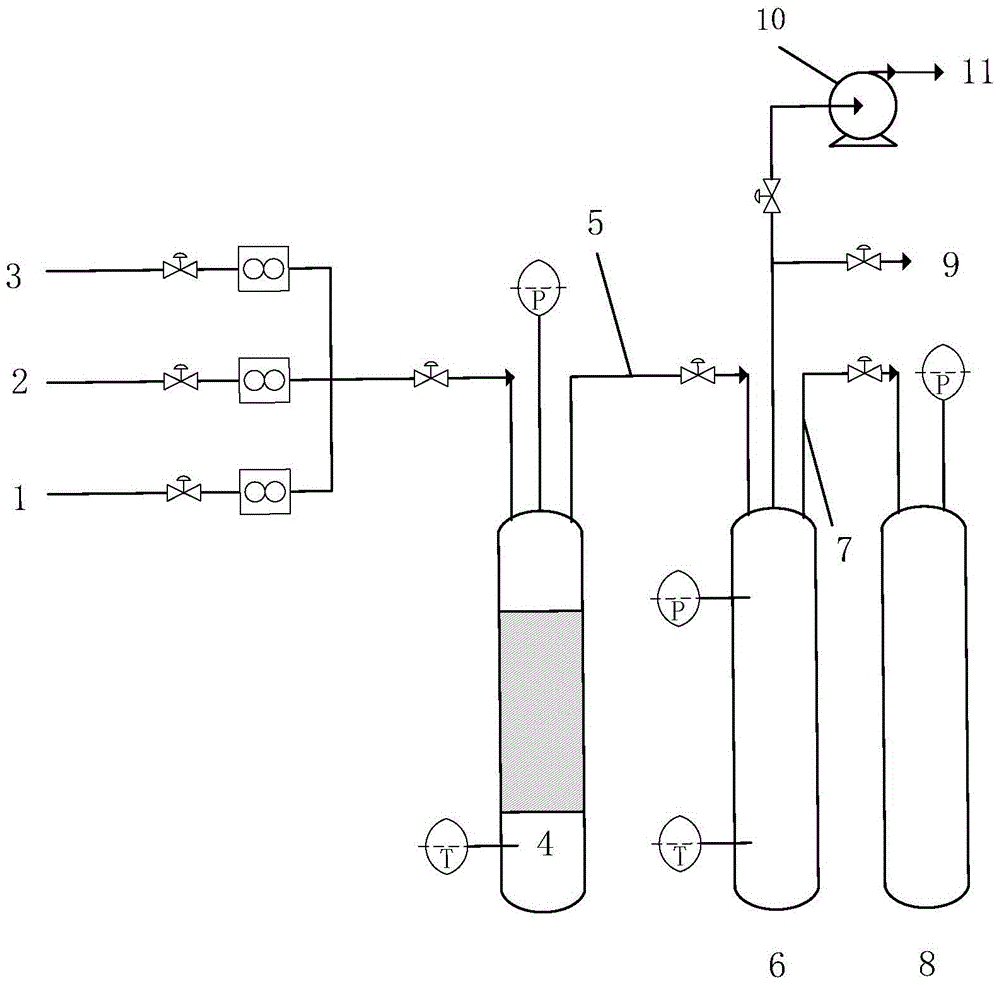

[0046] A schematic diagram of a preparation device for chlorine trifluoride is as figure 1 As shown, the device comprises a catalytic reactor 4, a cryogenic collector 6, a chlorine trifluoride storage tank 8 and a vacuum pump 10;

[0047] Wherein, the catalytic reactor 4 is provided with an air inlet pipe, and the air inlet pipe includes a fluorine gas pipe 1, a chlorine gas pipe 2 and a dilution gas pipe 3; an emptying pipe is arranged on the cryogenic collector, and the emptying pipe includes a normal pressure emptying pipe 9 And vacuum evacuation pipe 11, vacuum pump 10 is installed at the outlet end of vacuum evacuation pipe 11;

[0048] The overall connection relationship is:

[0049] The catalytic reactor 4 is connected with the low-temperature collector 6 through a connection pipe one 5; the low-temperature collector 6 is connected with the chlorine trifluoride storage tank 8 through a connection pipe two 7;

[0050] The constituent materials of the cryogenic collecto...

Embodiment 2

[0054] A preparation method for chlorine trifluoride, the specific steps of the method are as follows:

[0055] (1) Put cobalt fluoride pellets with a diameter of 10 to 20mm into the reactor, first vacuumize the various parts of the device with a vacuum pump; then use a diluted gas to purge and replace the residual air and moisture in the system ; Chlorine, fluorine, and nitrogen are passed into the catalytic reactor at a flow rate of 0.1L / min, 0.3L / min, and 1.2L / min respectively, and the operating pressure of the catalytic reactor is set to 0.6MPa, at 400°C Reaction, obtain product 1;

[0056] (2) Pass the product 1 into the liquefaction collector, set the operating pressure of the liquefaction collector to 0.6MPa, cool and liquefy at 0°C, and send the low-boiling point gas impurities to the tail gas treatment system through the exhaust pipeline. Dispose of and empty. After 20 hours, the introduction of chlorine and fluorine gas was stopped, and the heating of the reactor w...

Embodiment 3

[0062] A preparation method for chlorine trifluoride, the specific steps of the method are as follows:

[0063] (1) Put nickel fluoride pellets with a diameter of 10-20mm into the reactor, first vacuumize and pre-treat each part of the device with a vacuum pump; then use a diluted gas to purge and replace the residual air and moisture in the system ; Pass chlorine, fluorine, and helium into the catalytic reactor at a flow rate of 1L / min, 4L / min, and 40L / min respectively, set the operating pressure of the catalytic reactor to -0.09MPa, and react at 100°C , to obtain the product 1;

[0064] (2) Pass the product 1 into the liquefaction collector, set the operating pressure of the liquefaction collector to -0.09MPa, cool and liquefy at -100°C, and send the low-boiling point gas impurities to the tail gas treatment system through the exhaust pipeline. Void after chemical treatment. After 3 hours, the introduction of chlorine and fluorine gas was stopped, and the heating of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com