Water purifying agent for sewage resulting from recovery of waste/used tires and sewage treatment method

A technology of waste tires and water purifiers, applied in biological water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as pollution and air pollution, and achieve high safety and clean water Fast, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

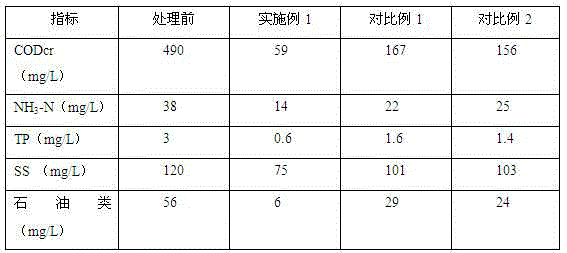

Embodiment 1

[0034] Adopt the method for water body treatment of water purifying agent that produces sewage in waste tire recycling of the present invention, this method comprises the following steps:

[0035] First add flocculation water purifier to the sewage, stir evenly at a speed of 15 rpm, stir for 0.5 hours, and let it stand for 4 hours; the flocculation water purifier is: polyaluminum chloride 16, polyacrylamide 12, ferrous sulfate 10. Aluminum sulfate 12;

[0036] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 15 rpm, stir for 0.6 hours, and let stand for 4 hours; the microbial water purifiers are nitrifying bacteria Powder 1.5, Denitrification Paracoccus powder 0.9, Pseudomonas aeruginosa powder 0.9, Candida lipolytica powder 0.5, Bacillus megaterium powder 0.5;

[0037] Then add the enzyme preparation in the above steps, stir evenly a...

Embodiment 2

[0050] Adopt the method for the water body treatment of the water purifying agent that produces sewage in the above-mentioned waste tire recycling, this method comprises the following steps:

[0051] First add flocculation water purifier to the sewage, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 2 hours; flocculation water purifier is: polyaluminum chloride 4, polyacrylamide 4, ferrous sulfate 2. Aluminum sulfate 3;

[0052] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 2 hours; microbial water purifiers are: nitrifying bacteria Bacteria powder 0.5, Denitrification Paracoccus bacteria powder 0.4, Pseudomonas aeruginosa bacteria powder 0.2, Candida lipolytica bacteria powder 0.2, Bacillus megaterium bacteria powder 0.2;

[0053] Then add the enzyme preparation...

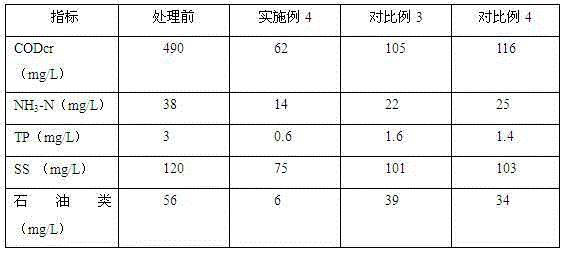

Embodiment 3

[0055] Adopt the method for the water body treatment of the water purifying agent that produces sewage in the above-mentioned waste tire recycling, this method comprises the following steps:

[0056] First add flocculation water purifier to the sewage, stir evenly at a speed of 20 rpm, stir for 1 hour, and let it stand for 5 hours; the flocculation water purifier is: polyaluminum chloride 16, polyacrylamide 16, ferrous sulfate 12. Aluminum sulfate 16;

[0057] Release the clear water in the upper layer of the above-mentioned sewage, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 20 rpm, stir for 1 hour, and let stand for 6 hours; the microbial water purifiers are: nitrifying bacteria Bacteria powder 2.0, Denitrification Paracoccus bacteria powder 1.5, Pseudomonas aeruginosa bacteria powder 1.2, Candida lipolytica bacteria powder 0.8, Bacillus megaterium bacteria powder 0.8;

[0058] Then add the enzyme pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com