Water purifying agent for wastewater treatment of tire production enterprises and wastewater treatment method

A technology of wastewater treatment and water purifier, which is applied in the field of water purifiers to treat waste water from tire manufacturing enterprises, and water purifiers for tire manufacturing wastewater treatment. It can solve problems such as pollution and achieve high transparency, high safety, and no secondary pollution. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

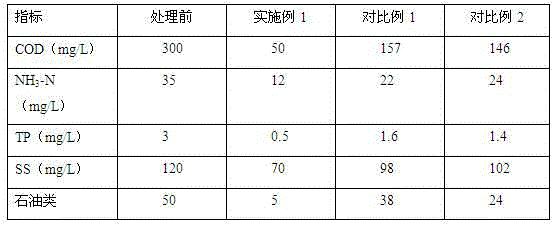

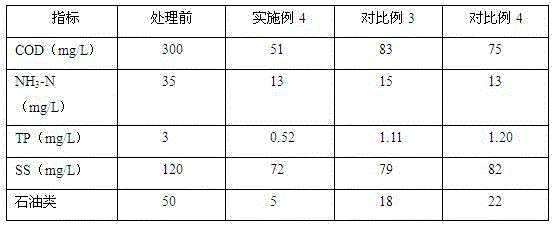

Examples

Embodiment 1

[0028] The tire manufacturing enterprise wastewater treatment method comprises the following steps:

[0029] First add inorganic water purifying agent to the waste water, stir evenly at a speed of 15 rpm, stir for 0.5 hours, and let it stand for 4 hours; the inorganic water purifying agent is: polyaluminum chloride 16, polyacrylamide 12, ferrous sulfate 10. Aluminum sulfate 12;

[0030] Release the clear water in the upper layer of the above-mentioned waste water, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 15 rpm, stir for 0.6 hours, and let stand for 4 hours; the microbial water purifiers are nitrifying bacteria powder 1.2, denitrifying paracoccus powder 0.9, sulfur bacteria powder 0.6, aniline degrading bacteria powder 0.9;

[0031] Add the enzyme preparation in the above steps, stir evenly at a speed of 15 rpm, stir for 0.5 hours, and let stand for 4 hours. The enzyme preparation is: pectinase 0.8,...

Embodiment 2

[0045] The waste water treatment method of tire manufacturing enterprises comprises the following steps:

[0046] First add inorganic water purifying agent to the waste water, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let it stand for 2 hours; the inorganic water purifying agent is: polyaluminum chloride 5, polyacrylamide 4, ferrous sulfate 2. Aluminum sulfate 5;

[0047]Release the clear water in the upper layer of the above-mentioned waste water, remove the pollutants at the bottom, add microbial water purifiers to the upper clear water, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 2 hours; the microbial water purifiers are: nitrifying bacteria Bacteria powder 0.5, denitrification paracoccus bacteria powder 0.4, sulfur bacteria powder 0.2, aniline degrading bacteria powder 0.3;

[0048] Then add the enzyme preparation in the above steps, stir evenly at a speed of 10 rpm, stir for 0.2 hours, and let stand for 3 hours. The enzyme pre...

Embodiment 3

[0050] The waste water treatment method of tire manufacturing enterprises comprises the following steps:

[0051] First add inorganic water purifying agent to the waste water, stir evenly at a speed of 20 rpm, stir for 1 hour, and let it stand for 5 hours; the inorganic water purifying agent is: polyaluminum chloride 20, polyacrylamide 16, ferrous sulfate 15. Aluminum sulfate 16;

[0052] Release the clear water in the upper layer of the above-mentioned waste water, remove the pollutants at the bottom, add a microbial water purifier to the upper clear water, stir evenly at a speed of 20 rpm, stir for 1 hour, and let stand for 6 hours; the microbial water purifier is: nitrifying bacteria Bacteria powder 2.0, denitrification paracoccus bacteria powder 1.4, sulfur bacteria powder 0.8, aniline degrading bacteria powder 1.2;

[0053] Then add the enzyme preparation in the above steps, stir evenly at a speed of 20 rpm, stir for 1 hour, and let stand for 8 hours. The enzyme preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com