Treatment system and method for biogas slurry produced from anaerobic fermentation of kitchen waste

A technology of kitchen waste and anaerobic fermentation, which is applied in the field of anaerobic fermentation biogas slurry treatment system of kitchen waste, can solve problems such as easy to generate stench, large floor area, complex composition, etc., and achieve stable operation and guarantee running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

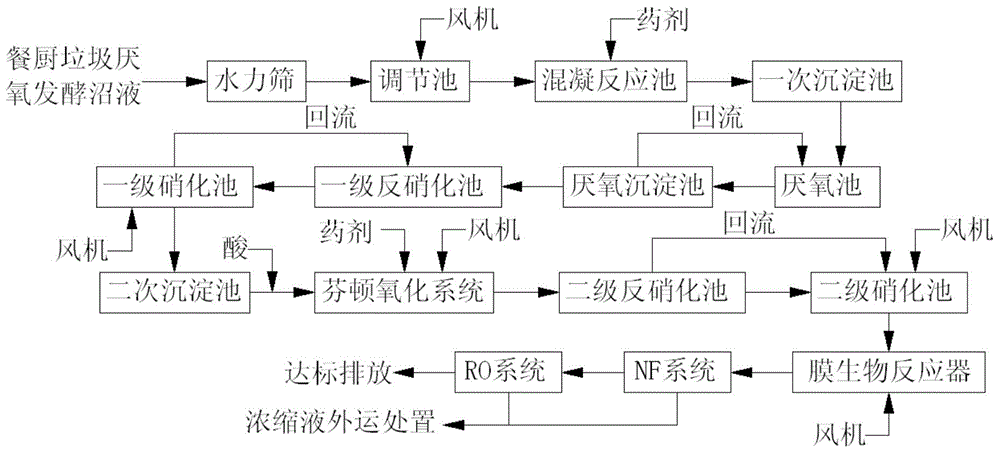

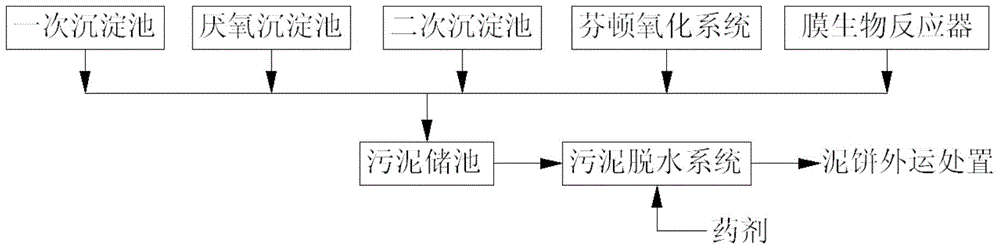

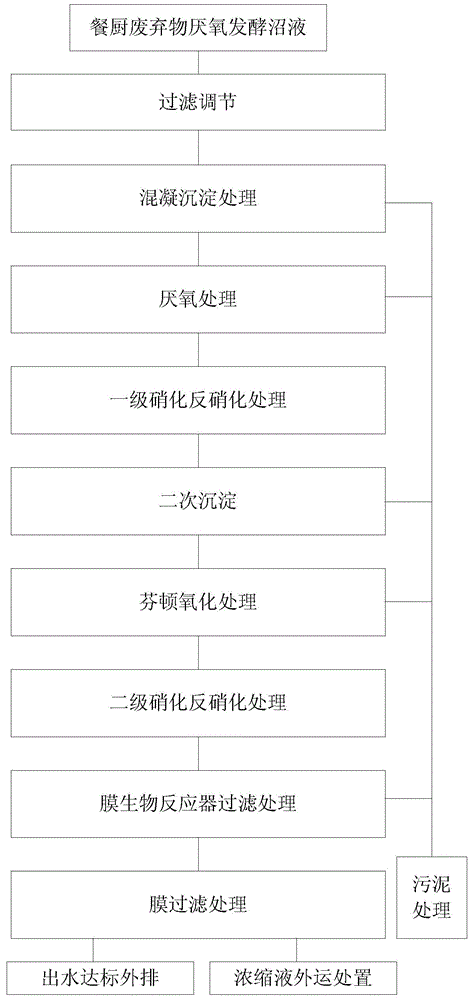

[0044] A kind of treatment method of kitchen waste anaerobic fermentation biogas slurry provided in this embodiment adopts the system of the present invention (see figure 1 , 2 ), including the following steps (such as image 3 shown):

[0045] (1) The biogas slurry from the anaerobic fermentation of kitchen waste is filtered by a hydraulic sieve to remove part of the suspended solids, and then enters the regulating tank to adjust the water quality and quantity. 0.04m 3 / m 2 Min;

[0046] (2) The biogas slurry in the adjustment pond enters the coagulation reaction system after being lifted by the pump. Add polyaluminum sulfate in the mixing tank, the dosage is 1000mg / L, and add cationic polyacrylamide in the reaction tank, the dosage is 15mg / L. The mixed solution after full flocculation reaction enters the primary sedimentation tank for mud-water separation;

[0047] (3) The supernatant after a precipitation enters the anaerobic treatment system. The organic load of th...

Embodiment 2

[0056] This embodiment provides a method for treating kitchen waste anaerobic fermentation biogas slurry, using the system of the present invention, comprising the following steps:

[0057] (1) The biogas slurry from the anaerobic fermentation of kitchen waste is screened by a hydraulic sieve to remove part of the suspended solids, and then enters the regulating tank to adjust the water quality and quantity. 0.05m 3 / m 2 Min;

[0058] (2) The biogas slurry in the adjustment pond enters the coagulation reaction system after being lifted by the pump. Add polyaluminum sulfate in the mixing tank, the dosage is 1500mg / L, and add cationic polyacrylamide in the reaction tank, the dosage is 20mg / L. The mixed solution after full flocculation reaction enters the primary sedimentation tank for mud-water separation;

[0059] (3) The supernatant after a precipitation enters the anaerobic treatment system. The organic load of the anaerobic tank is 5kgCOD / (m 3 d), the anaerobic sedimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com